Coarse food grain fluffy cake capable of applying microcapsule technology, and preparation method for coarse food grain fluffy cake

A microcapsule technology and microcapsule technology, applied in the field of biscuits, can solve problems such as failure to meet shelf life requirements and microbial contamination, and achieve the effects of improving oxidative deterioration, reducing direct contact, and slowing down oxidative degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

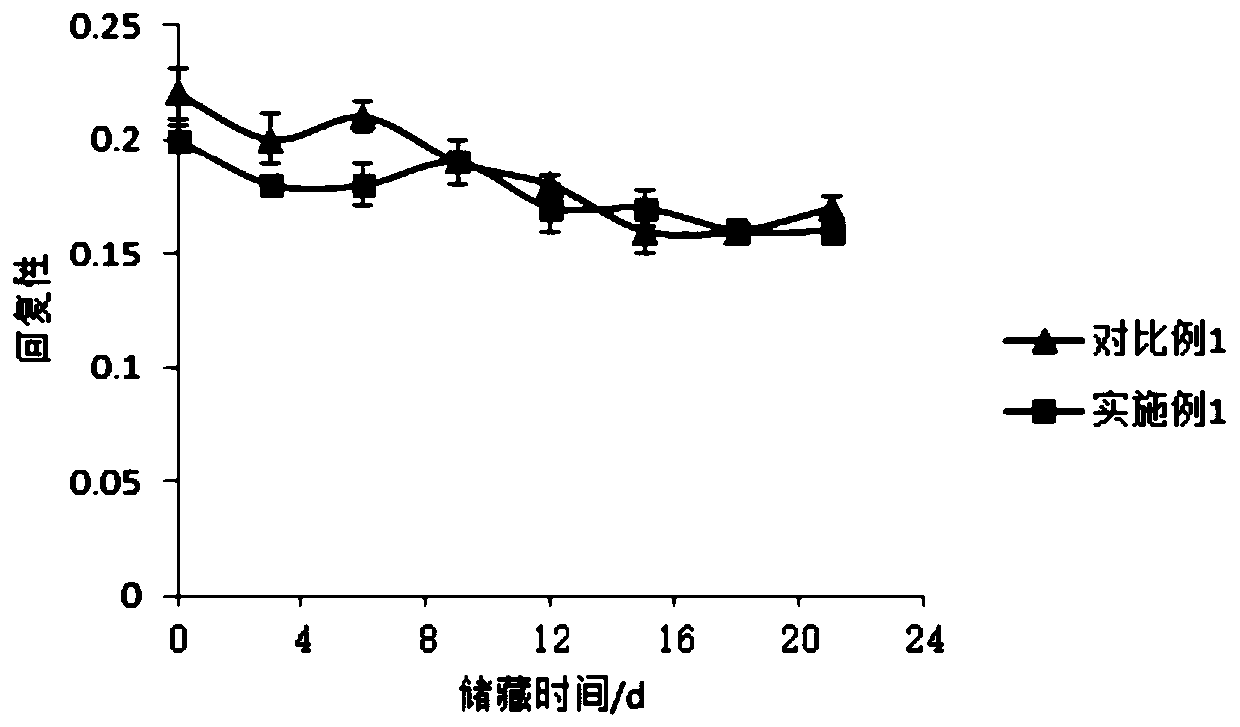

Image

Examples

Embodiment 1

[0044]A coarse grain soft cake using microcapsule technology, which includes the following components by weight: 19g of low-gluten wheat flour, 13g of highland barley flour, 7g of tartary buckwheat flour, 4.5g of oatmeal flour, 3g of black soybean flour, and 2.5g of soybean flour. g. Mung bean flour 1.8g, wheat bran powder 1.7g, linseed oil microcapsules 9.5g, egg liquid 11g, high calcium milk powder 5.2g, xylitol 7g, white sugar 6g, baking powder 0.4g, baking soda 0.4g , edible salt 0.5g, water 7.5g.

[0045] The linseed oil microcapsules in this example include the following components by weight: 60 g of finished linseed oil, 50 g of soybean protein isolate, 50 g of maltodextrin, 3 g of linseed gum, and 907 mL of water.

[0046] Its preparation method is as follows:

[0047] ①Preparation of linseed oil microcapsules: Dissolve soybean protein isolate and maltodextrin in distilled water at 70°C, then add linseed oil, stir well, add linseed gum to form a primary emulsion, and ...

Embodiment 2

[0052] A coarse grain soft cake using microcapsule technology, which comprises the following components by weight: 20g of low-gluten wheat flour, 15g of highland barley flour, 8g of tartary buckwheat flour, 3.5g of oatmeal powder, 3.5g of black soybean flour, and 3.5g of soybean flour 3g, mung bean flour 3g, wheat bran powder 1g, linseed oil microcapsules 8.5g, egg liquid 12g, high calcium milk powder 2g, xylitol 10g, aspartame 0.15g, baking powder 0.4g, edible salt 0.3g , water 6.8g.

[0053] The linseed oil microcapsules in this example include the following components by weight: 80 g of finished linseed oil, 110 g of modified starch, 8 g of monoglyceride, 5 g of sucrose ester, and 797 mL of water.

[0054] Its preparation method is as follows:

[0055] ①Preparation of linseed oil microcapsules: Dissolve modified starch in distilled water at 90°C, then add linseed oil, stir well, add monoglyceride and sucrose ester to form a primary emulsion, and emulsify at a high speed of...

Embodiment 3

[0060] A coarse grain soft cake using microcapsule technology, which comprises the following components by weight: 16g of low-gluten wheat flour, 12.5g of highland barley flour, 7.5g of tartary buckwheat flour, 3.8g of oatmeal powder, 3.4g of black soybean flour, soybean flour Raw flour 3.2g, mung bean raw flour 3.2g, wheat bran powder 3g, linseed oil microcapsules 10g, egg liquid 9g, high calcium milk powder 4g, white sugar 5g, steviol glycoside 0.1g, baking soda 0.6g, ammonium bicarbonate 0.5 g, edible salt 0.45g, water 10.35g.

[0061] The linseed oil microcapsules in this example include the following components by weight: 45 g of finished linseed oil, 40 g of whey protein, 30 g of modified starch, 9 g of lecithin, and 876 mL of water.

[0062] Its preparation method is as follows:

[0063] ① Preparation of linseed oil microcapsules: Dissolve whey protein and modified starch in distilled water at 75°C, then add finished linseed oil, stir well, and add lecithin to form pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com