Method for screening solvent treatment process parameters of polymer porous ion conduction membrane for flow battery

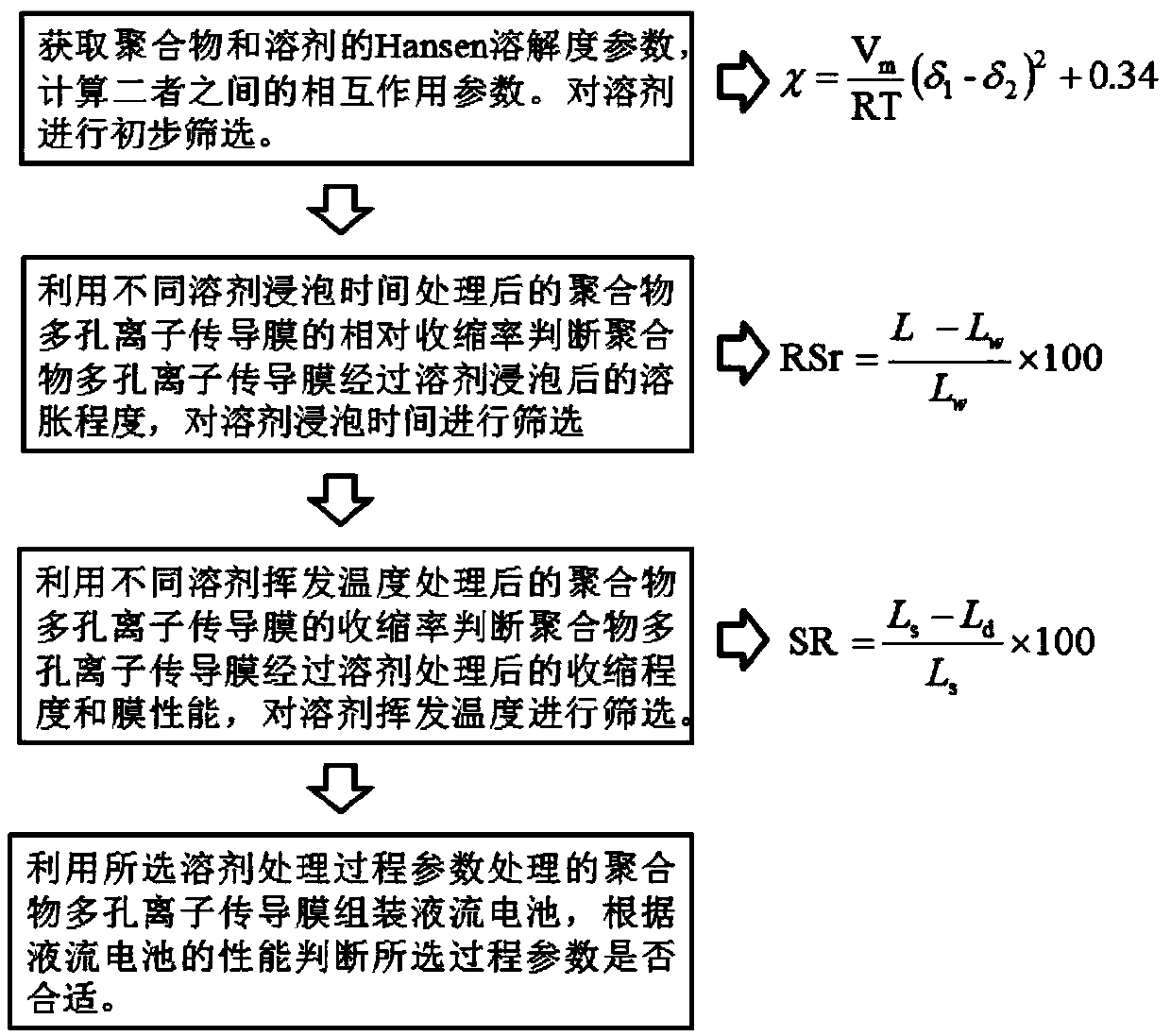

An ion-conducting membrane and treatment process technology, which is used in the field of screening parameters of the solvent treatment process of polymer porous ion-conducting membranes, can solve problems such as high cost and complicated procedures, and achieve optimized performance, high ion selectivity, and excellent proton conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

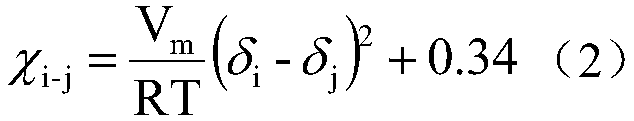

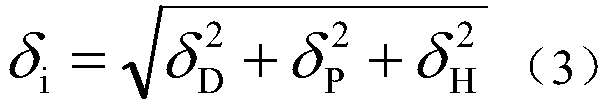

[0064] Porous ion-conducting membranes were prepared using polybenzimidazole as the membrane material, and isopropanol, acetone, and ethyl acetate were used as optional processing solvents. Firstly, obtain the Hansen solubility parameters of polymers and solvents through literature review or equation calculation. Then, the interaction parameter χ between the polymer and the solvent was calculated, and the above-mentioned candidate solvents were initially screened.

[0065] The screening process is as follows:

[0066] When using isopropanol as a processing solvent, according to the literature review, it can be known that the δ of isopropanol IPA =23.5MPa 1 / 2 , V m =76.8L mol -1 .

[0067] According to literature review PBI's F i , n i , S j and m j As shown in Table 1:

[0068] Table 1

[0069]

[0070] through the equation Calculate δ PBI =23.29MPa 1 / 2 .

[0071] Take R=8.314J mol -1 K -1 , T=298K, through the equation Calculated χ PBI-IPA =0.382<2...

Embodiment 2

[0094] Porous PBI membranes were prepared with polybenzimidazole (PBI) as the membrane material, and isopropanol and isopropanol aqueous solution were selected as alternate solvents. Firstly, obtain the Hansen solubility parameters of polymers and solvents through literature review or equation calculation. Then, the interaction parameter χ between the polymer and the solvent was calculated, and the above-mentioned candidate solvents were initially screened.

[0095] The screening process is as follows:

[0096] According to literature review, it can be known that the δ of sleep Water =47.9MPa 1 / 2 , V m =18L mol -1 .

[0097] From the above calculations, it can be seen that δ PBI =23.29MPa 1 / 2 . Take R=8.314J mol -1 K -1 , T=298K, through the formula Calculated χ PBI-Water =4.261.

[0098] When isopropanol: water=9:1, by the equation χ=∑X i Y j x i-j =0.9×0.382+0.1×4.261 It can be seen that the χ=0.7699<2.5 between PBI and the treatment solvent meets the requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Effective area | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com