Photo-thermal double-curing 3D printing method by using ring-opening metathesis polymerization (ROMP) and product thereof

A ring-opening metathesis polymerization and 3D printing technology, applied in the field of 3D printing, can solve the problems of ROMP light-dark dual-cured products becoming brittle and losing toughness, achieving good toughness, improving elongation at break, and broadening the application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of polyurethane polyacrylate: Mix 1 mol of PPG-1000 with 0.5% of the weight of PPG-1000 of DBT and add dropwise to 2 mol of HDI, react at 60°C for 1 hour, then add 2 mol of HEA, and react at 60°C for 3 hours. To obtain polyether urethane acrylate;

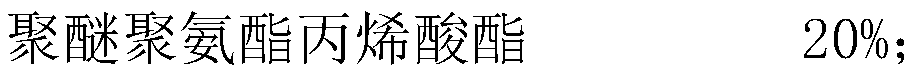

[0028] (2) Light-heat dual curing 3D printing: The polyether urethane acrylate obtained in step (1) is mixed with ACMO and TPO according to the following mass percentages first, and then 3D printing is performed using a light curing printer to obtain a photopolymer, and testing The glass transition temperature of the photopolymer is -15°C, which is lower than room temperature; then according to the following mass percentages, the polyether urethane acrylate, ACMO, TPO, Umicore 22 catalyst and dicyclopentadiene are mixed and photocured for printing, and then heated to After curing at 100°C for 2 hours, a 3D printed product was obtained; the catalyst was Umicore brand Umicore 22, specifically (1,3-bis(2,4,6-trimet...

Embodiment 2

[0032] (1) Preparation of polyurethane polyacrylate: Mix 1mol PCDL-1000 with 0.5% of the weight of PCDL-1000 DBT and add dropwise to 2mol HDI, react at 60℃ for 1h, then add 2mol HEMA, react at 60℃ for 3h, Obtain polyester polyurethane acrylate;

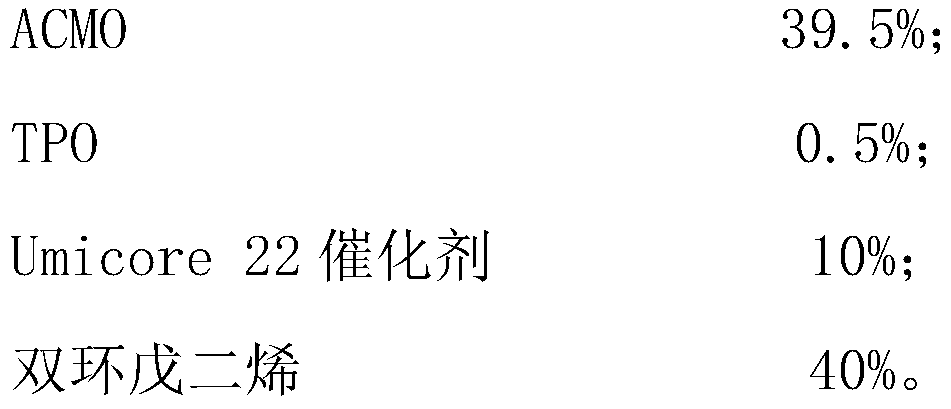

[0033] (2) Light-heat dual curing 3D printing: The polyester polyurethane acrylate obtained in step (1) is mixed uniformly with HEMA and TPO according to the following mass percentages, and 3D printing is performed using a light curing printer to obtain a polymer. Test the polymer The glass transition temperature is -9℃, which is lower than room temperature; then according to the following mass percentages, mix the polyester urethane acrylate, HEMA, TPO, catalyst and cyclopentadiene uniformly, then light-curing and printing, then heat to 90℃ and cure for 2h , To obtain 3D printed products; wherein the catalyst is Umicore brand Umicore 22, specifically (1,3-bis(2,4,6-trimethylphenyl) 2-imidazolidinyl subunit) dichloro (3 -Phenyl-1H-inden...

Embodiment 3

[0036] (1) Preparation of polyurethane polyacrylate: mix 1 mol of PCDL-1000 with 0.5% of the weight of PCDL-1000 of DBT and add dropwise to 2 mol of HDI, react at 60°C for 1 hour, then add 2 mol of HEA, and react at 60°C for 3 hours. Obtain polyester polyurethane acrylate;

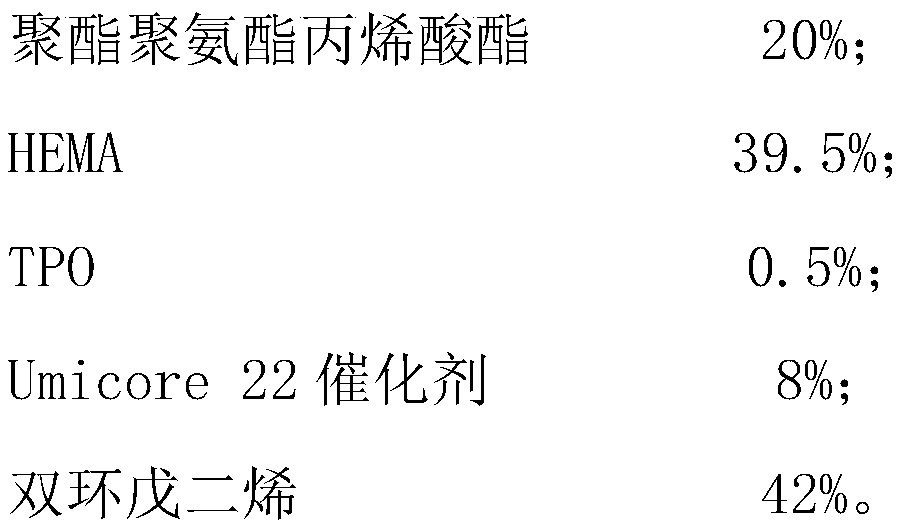

[0037] (2) Light-heat dual curing 3D printing: The polyester polyurethane acrylate obtained in step (1) is mixed uniformly with ACMO, TPO and dicyclopentadiene acrylate according to the following mass percentages, and 3D printing is performed using a light curing printer to obtain Polymer, the glass transition temperature of the tested polymer is 6℃, which is lower than room temperature; then according to the following mass percentages, the polyester urethane acrylate, ACMO, TPO, Umicore 22 catalyst and dicyclopentadiene are mixed uniformly and then light-cured 3D printing , And then heated to 60°C and cured for 6 hours to obtain 3D printed products. The acrylate group of dicyclopentadiene acrylate undergoes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com