Preparation process and detection method of microcapsule toughened and reinforced polypropylene composite material

A composite material and preparation technology, which is applied in the direction of analyzing materials, applying stable tension/pressure to test material strength, measuring devices, etc., can solve the problems of poor low temperature impact resistance, easy aging, etc., to prolong life and firmly bond the interface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

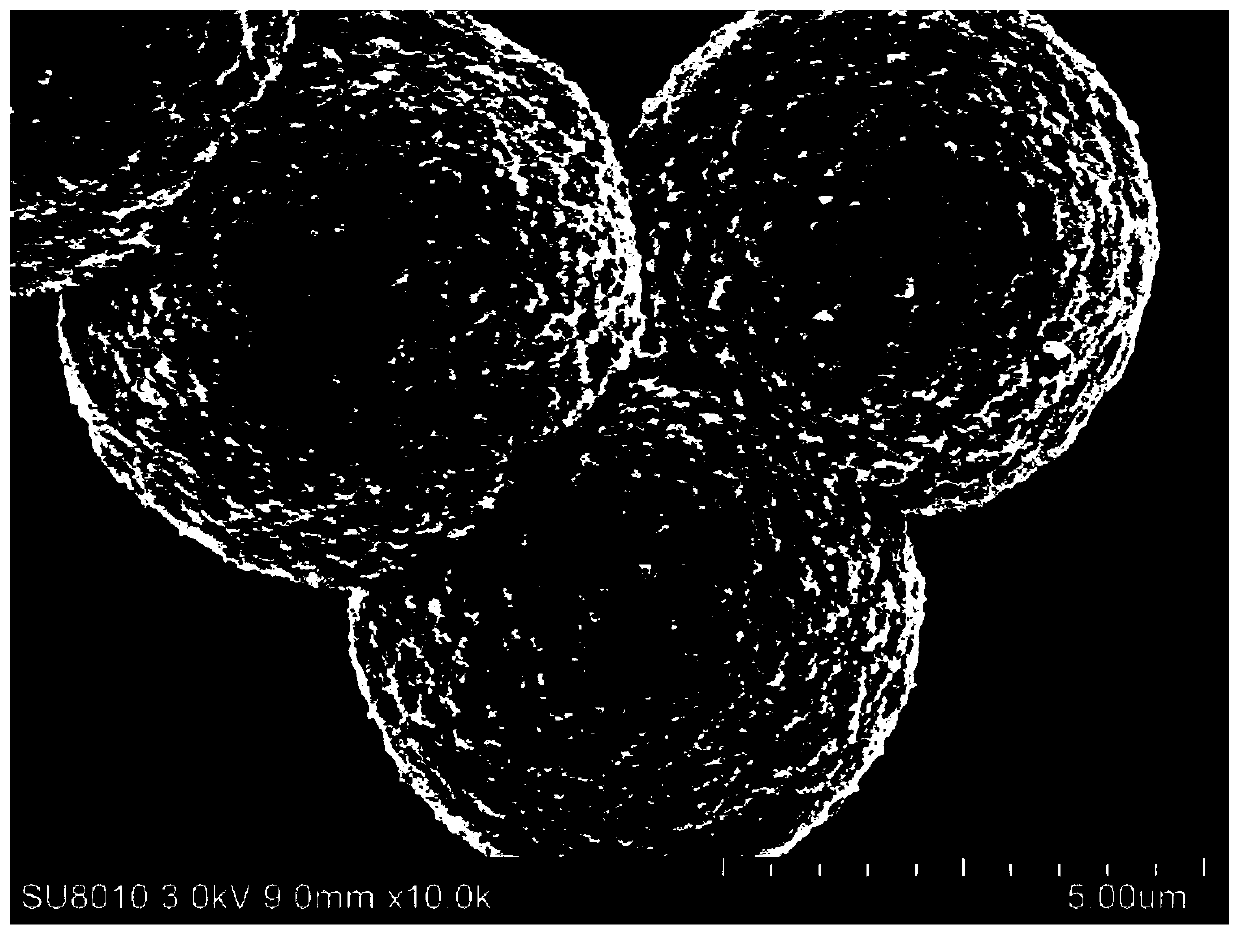

[0051] Preparation of ST-UF microcapsules:

[0052] 1) Weigh urea and formaldehyde solution according to the mass ratio of 10:18, add the two into the flask, adjust the pH of the system to 8 with triethanolamine, then put the flask into a constant temperature water bath at 74°C, and stir for 1 hour. Obtain the capsule wall prepolymer;

[0053] 2) According to the mass ratio, weigh 100 parts of styrene, 37 parts of epoxy resin, 4 parts of acetone and 39 parts of tributyl phosphate, add them into a three-necked flask and stir well, add 188 parts of 1% dodecyl An aqueous solution of sodium alkylbenzenesulfonate, 2 parts of n-octanol, and continuous stirring at 30°C and 750 rpm for 27 minutes to form a stable oil-in-water (O / W) emulsified solution, that is, the core material emulsion;

[0054] 3) Capsule wall coated capsule core: add the capsule wall prepolymer solution prepared in 1) into the core material emulsion under stirring conditions, and adjust the pH of the system to 3 ...

Embodiment 2

[0061] Preparation of ST-UF microcapsules:

[0062] 1) Weigh the urea and formaldehyde solution according to the mass ratio of 10:21, add the two into the flask, adjust the pH of the system to 7 with triethanolamine, then put the flask into a constant temperature water bath at 73°C, and stir for 1 hour. Obtain the capsule wall prepolymer;

[0063] 2) According to the mass ratio, weigh 100 parts of styrene, 30 parts of epoxy resin, 5 parts of acetone and 38 parts of tributyl phosphate, add them into a three-necked flask and fully stir them evenly, add 185 parts of 1% dodecyl An aqueous solution of sodium alkylbenzenesulfonate, 2.5 parts of n-octanol, and continuous stirring at 30°C and 500 rpm for 26 minutes to form a stable oil-in-water (O / W) emulsified solution, that is, the core material emulsion;

[0064] 3) Capsule wall-coated capsule core: Add the capsule wall prepolymer solution prepared in 1) into the core material emulsion under stirring conditions, and adjust the pH ...

Embodiment 3

[0067] Preparation of ST-UF microcapsules:

[0068] 1) Weigh the urea and formaldehyde solution according to the mass ratio of 10:20, add the two into the flask, adjust the pH of the system to 7 with triethanolamine, then put the flask into a constant temperature water bath at 75°C, and stir for 1 hour. Obtain the capsule wall prepolymer;

[0069] 2) According to the mass ratio, weigh 100 parts of styrene, 35 parts of epoxy resin, 4 parts of acetone and 40 parts of tributyl phosphate, add them into a three-necked flask and stir well, add 190 parts of 1% dodecyl An aqueous solution of sodium alkylbenzenesulfonate, 2 parts of n-octanol, and continuous stirring at 30°C and 600 rpm for 27 minutes to form a stable oil-in-water (O / W) emulsified solution, that is, the core material emulsion;

[0070] 3) Capsule wall coated capsule core: add the capsule wall prepolymer solution prepared in 1) into the core material emulsion under stirring conditions, and adjust the pH of the system t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com