High-toughness epoxy resin grouting material for rapid repair of concrete structure joint

A concrete structure, epoxy resin technology, applied in the direction of epoxy resin glue, adhesive type, adhesive, etc., can solve the problems of high viscosity of liquid nitrile rubber, affecting material properties, degumming, etc., to achieve good wet bond strength , Long working time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

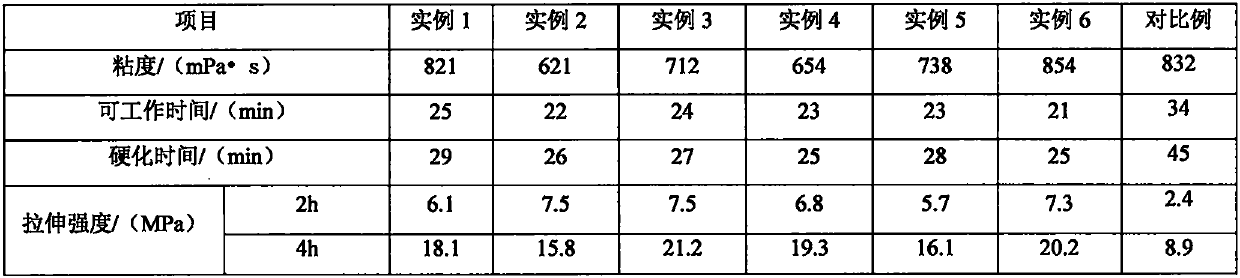

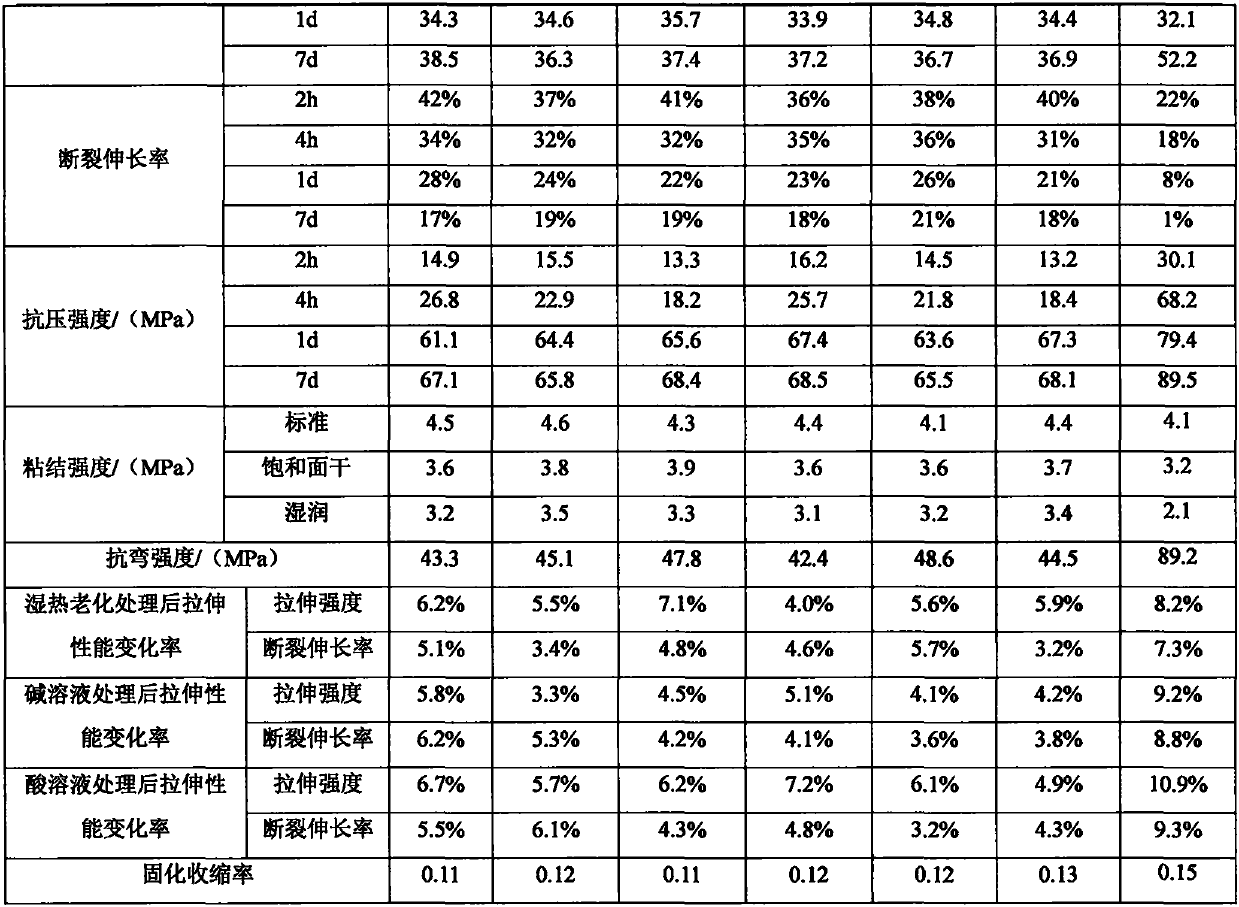

Examples

Embodiment 1

[0025] Component A:

[0026] 10 parts of bisphenol A type epoxy resin, 10 parts of hydrogenated bisphenol A type epoxy resin, 10 parts of bisphenol F type epoxy resin, 10 parts of aliphatic glycidyl ethers, 5 parts of diglycidyl adipate, 2 parts of diglycidyl phthalate, 3 parts of diglycidyl terephthalate, 4 parts of polyurethane modified epoxy resin, 5 parts of silicone modified epoxy resin, 1 part of nitrile rubber modified epoxy resin 10 parts, 10 parts of epoxy-terminated liquid nitrile rubber, 10 parts of aliphatic glycidyl ether;

[0027] Component B:

[0028] 10 parts of modified alicyclic amine, 10 parts of modified fatty amine, 5 parts of polymercaptan, 1 part of tertiary amine accelerator, 5 parts of amino-terminated liquid nitrile rubber, 5 parts of silicone defoamer, 1 part of fungicide 2 parts, 2 parts of antioxidant, 2 parts of heat stabilizer.

[0029] The volume ratio of A and B components is 1:0.4.

Embodiment 2

[0031] Component A:

[0032] 20 parts of bisphenol A type epoxy resin, 20 parts of hydrogenated bisphenol A type epoxy resin, 20 parts of bisphenol F type epoxy resin, 20 parts of aliphatic glycidyl ethers, 10 parts of diglycidyl adipate, 10 parts of diglycidyl phthalate, 10 parts of diglycidyl terephthalate, 30 parts of polyurethane modified epoxy resin, 30 parts of silicone modified epoxy resin, 10 parts of nitrile rubber modified epoxy resin 30 parts, 30 parts of epoxy-terminated liquid nitrile rubber, 40 parts of aliphatic glycidyl ether;

[0033] Component B:

[0034] 60 parts of modified alicyclic amine, 60 parts of modified fatty amine, 15 parts of polymercaptan, 5 parts of tertiary amine accelerator, 25 parts of amino-terminated liquid nitrile rubber, 15 parts of silicone defoamer, 5 parts of antifungal agent 5 parts, 5 parts of antioxidant, 5 parts of heat stabilizer.

[0035] The volume ratio of A and B components is 1:1.

Embodiment 3

[0037] 60 parts of bisphenol F-type epoxy resin, 20 parts of diglycidyl adipate, 40 parts of polyurethane modified epoxy resin, 20 parts of epoxy-terminated liquid nitrile rubber, and 25 parts of aliphatic glycidyl ether;

[0038] Component B:

[0039] 70 parts of modified alicyclic amine, 10 parts of polythiol, 3 parts of tertiary amine accelerator, 15 parts of amino-terminated liquid nitrile rubber, 10 parts of silicone defoamer, and 10 parts of heat stabilizer.

[0040] The volume ratio of A and B components is 1:0.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com