Method for preparing nickel-cobalt lithium manganate monocrystal cathode material by doping strontium

A technology of nickel cobalt lithium manganate and cathode material, applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problems of poor electrical properties such as specific capacity and cycle performance, and unstable secondary particles, etc. Achieve high specific capacity, facilitate lithium ion transport, and reduce side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

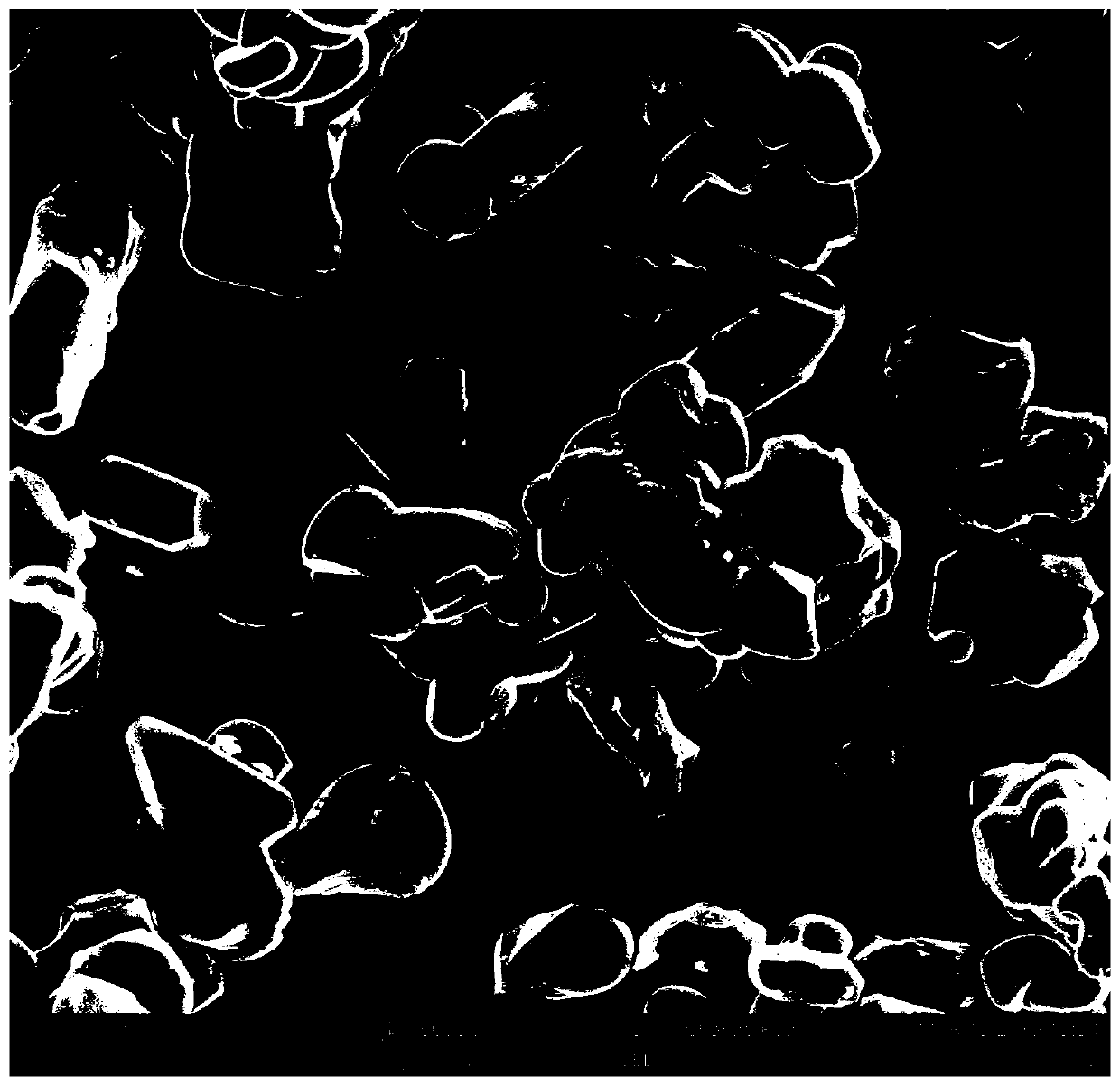

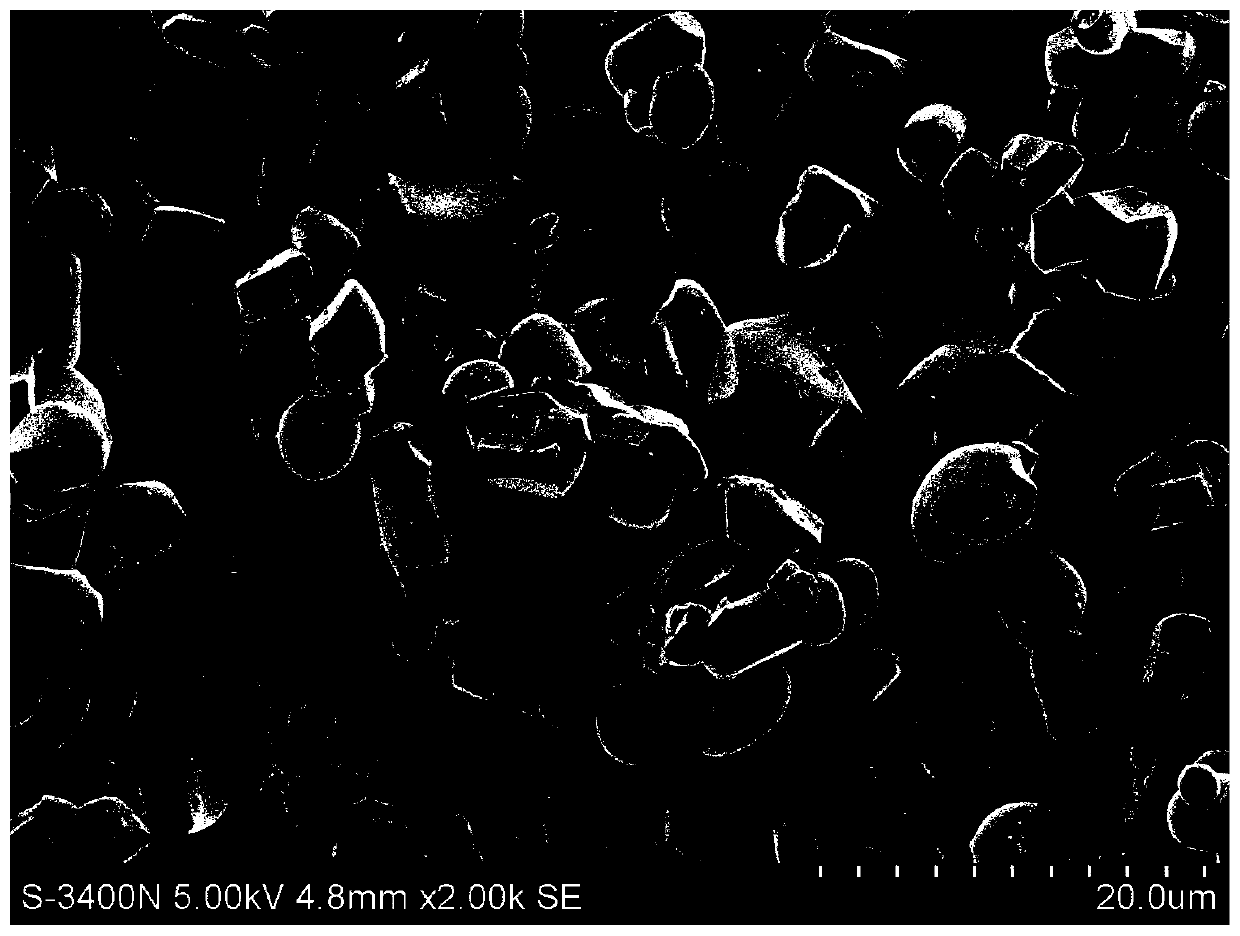

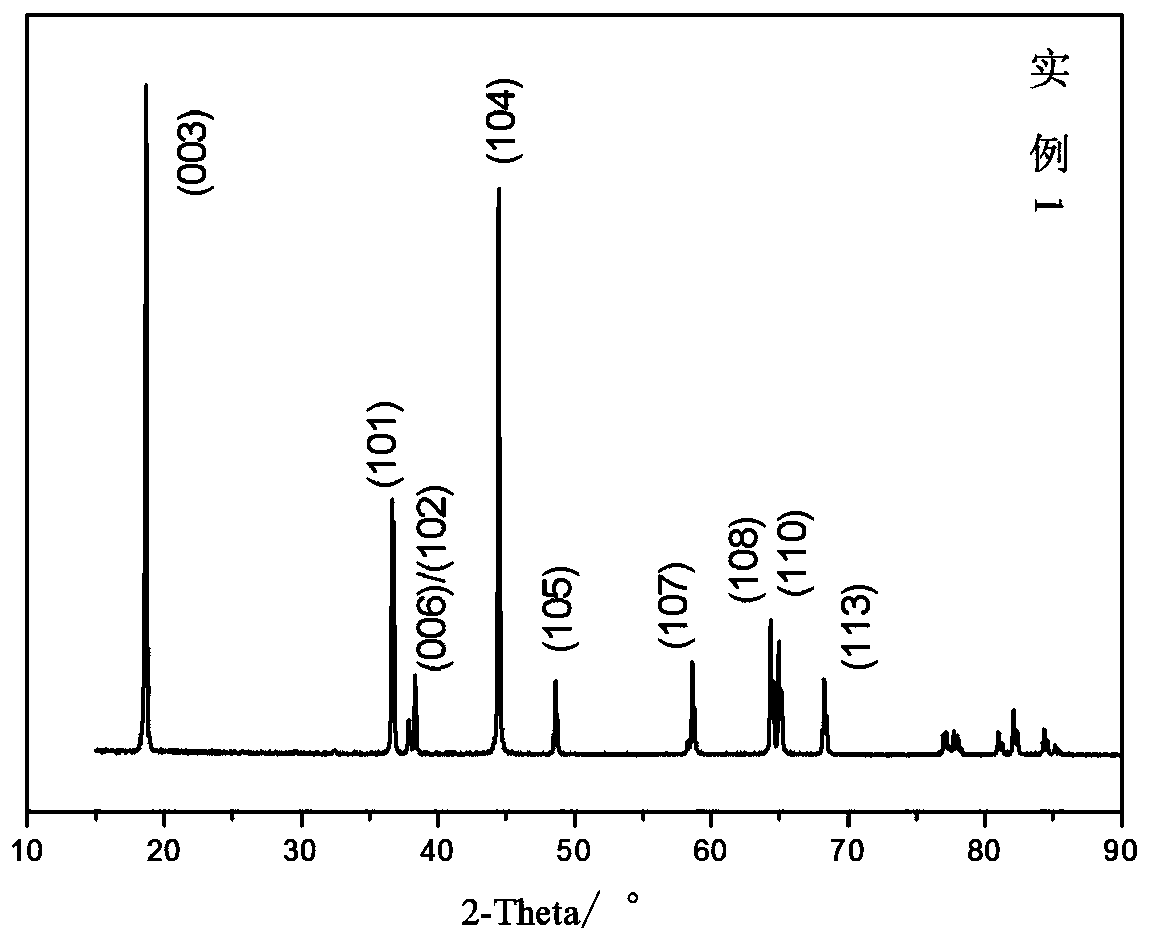

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing a nickel cobalt lithium manganate single crystal cathode material by doping strontium, and the specific steps are as follows:

[0035] Step 1. Put Ni 0.5 Co 0.2 Mn 0.3 (OH) 2 , Lithium carbonate and co-solvent are added to the high-mixer, first mix for 200s at a low speed of 200rpm, and then mix for 900s at a high speed of 900rpm; at the end of the mixing, a black mixed powder is obtained.

[0036] Step 2, the mixed powder of step 1 is calcined in a box furnace: under the condition of oxygen concentration of 40%, the temperature is increased from room temperature to 970°C at a rate of 2°C / min, and the temperature is kept at 970°C for 14h . After taking it out, grinding and passing through a 300-mesh sieve to obtain a primary calcined product.

[0037] Step 3: Put the primary calcined product obtained in step 2 into a box furnace, heat it from room temperature to 880°C at a rate of 2°C / min, keep it at 880°C for 5 hours and then c...

Embodiment 2

[0041] This embodiment provides a method for preparing a nickel cobalt lithium manganate single crystal cathode material by doping strontium, and the specific steps are as follows:

[0042] Step 1. Put Ni 0.5 Co 0.2 Mn 0.3 (OH) 2 , Lithium carbonate and co-solvent are added to the high-mixer, first mix for 200s at a low speed of 200rpm, and then mix for 900s at a high speed of 900rpm; at the end of the mixing, a black mixed powder is obtained.

[0043] Step 2, the mixed powder of step 1 is calcined in a box furnace: under the condition of oxygen concentration of 40%, the temperature is increased from room temperature to 970°C at a rate of 2°C / min, and the temperature is kept at 970°C for 14h . After taking it out, grinding and passing through a 300-mesh sieve to obtain a primary calcined product.

[0044] Step 3: Put the primary calcined product obtained in step 2 into a box furnace, heat it from room temperature to 880°C at a rate of 2°C / min, keep it at 880°C for 5 hours and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com