Organic-inorganic composite coating material, preparation method thereof, and method for preparing wear-resistant coating by using organic-inorganic composite coating material

A technology of inorganic composite and coating materials, which is applied in the field of organic-inorganic composite coating materials, preparation, and preparation of wear-resistant coatings. The preparation method is simple and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

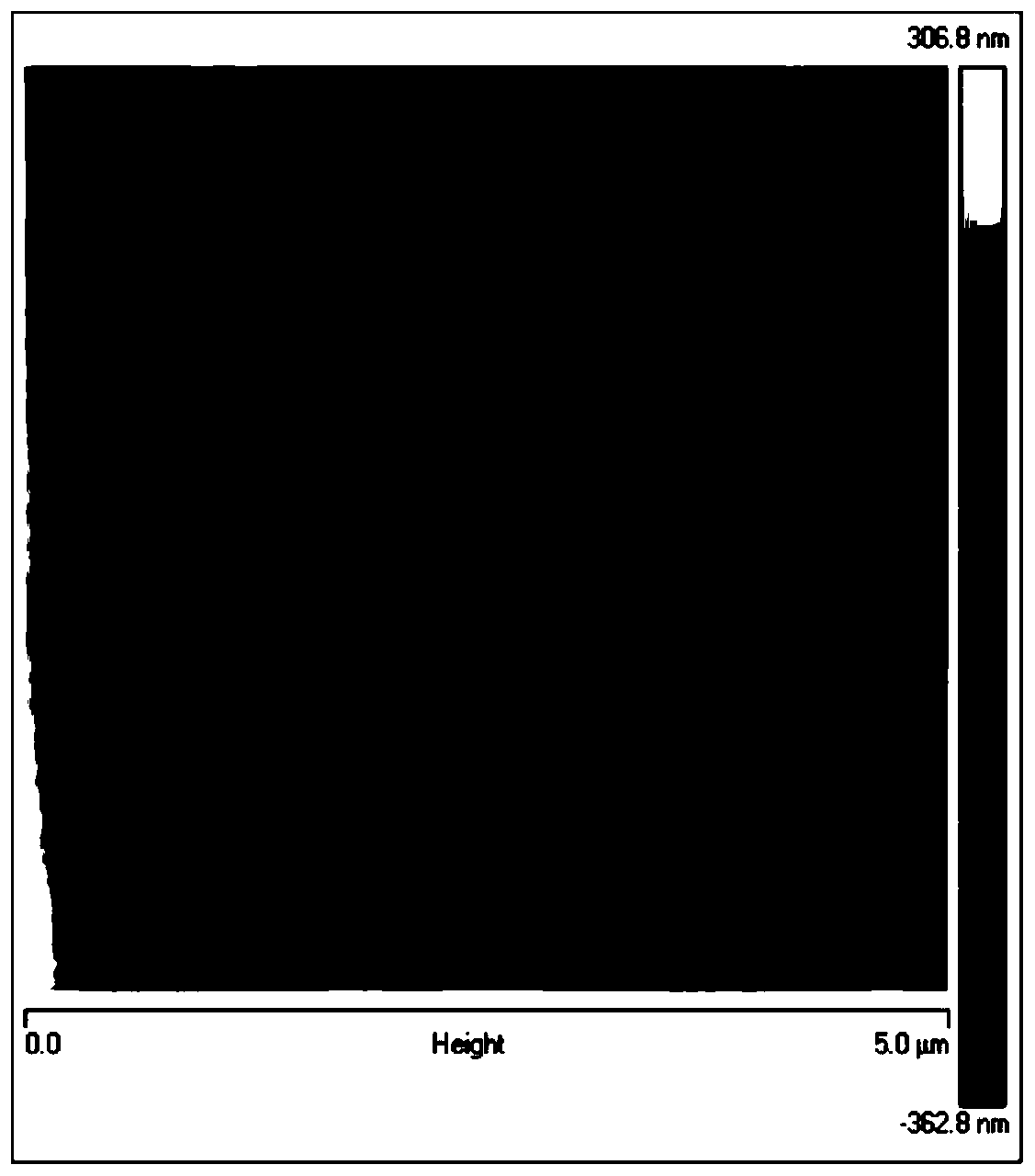

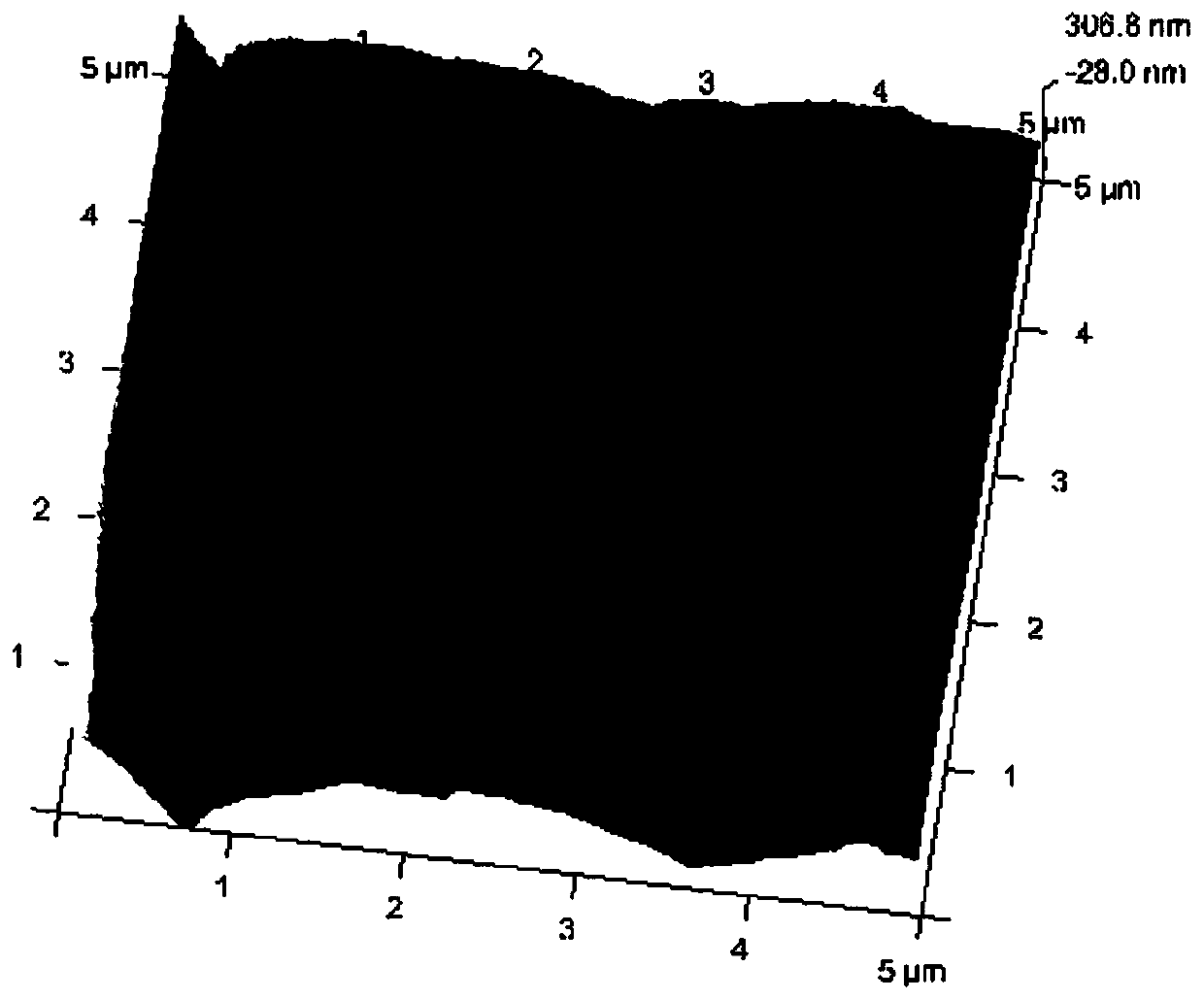

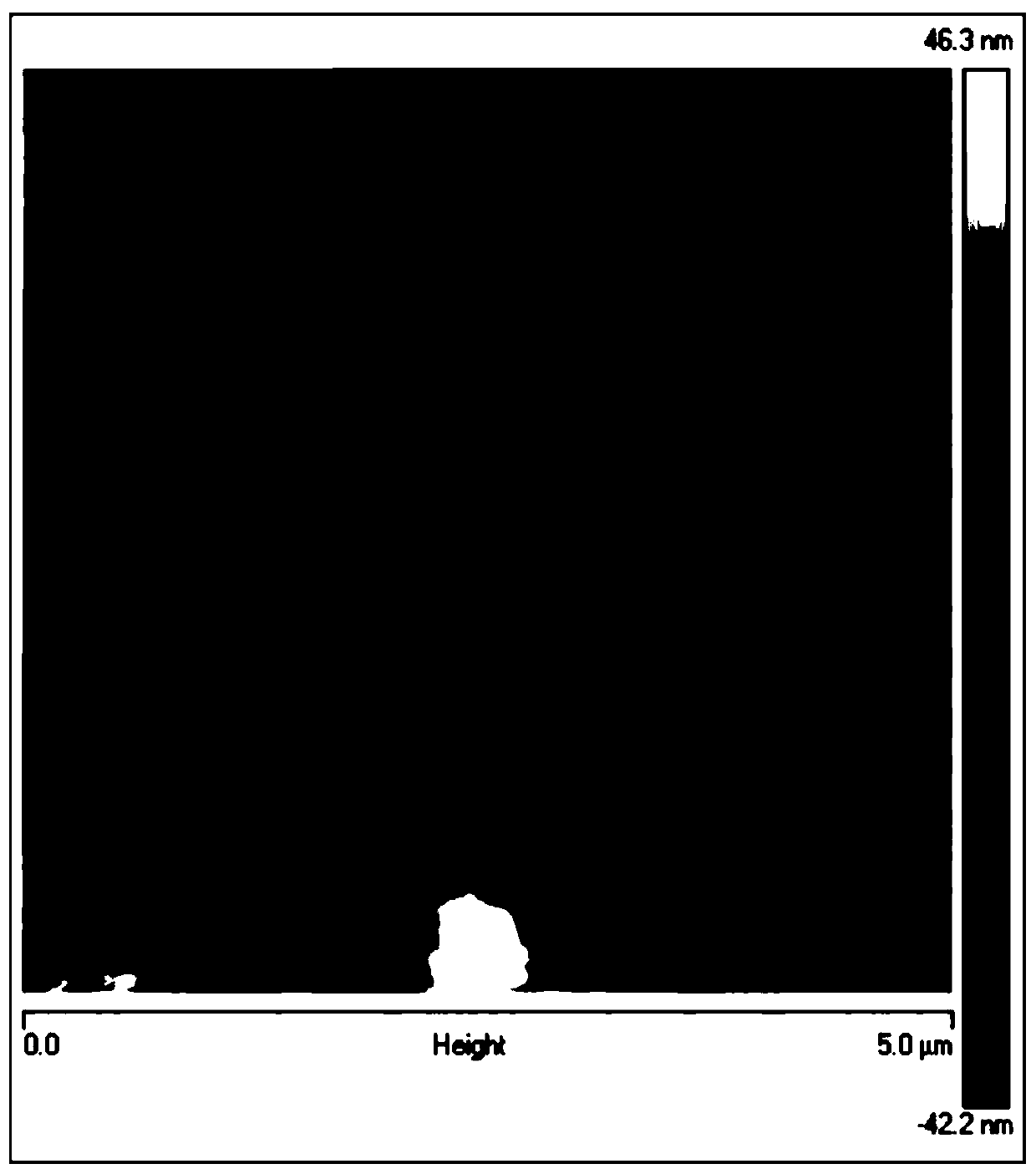

Image

Examples

Embodiment 1

[0045] An embodiment of the present invention provides a method for preparing an organic-inorganic composite coating material, comprising the following steps:

[0046] Step 1, dissolving butyl titanate in absolute ethanol to obtain a butyl titanate solution with a mass concentration of 7wt%, and adding dropwise an acetic acid solution with a mass concentration of 16wt% in the butyl titanate solution, the dropping speed rate of 0.05mL / s, stirred for 2 hours, sealed and aged for 12 hours to obtain titanium dioxide sol; wherein butyl titanate and CH in acetic acid 3 The molar ratio of COOH is 0.16:1;

[0047]Step 2, dissolve ethyl orthosilicate in absolute ethanol to obtain a solution of ethyl orthosilicate with a mass concentration of 25wt%, and add γ-(methacryloyl Oxygen)propyltrimethoxysilane, mixed evenly, adding water in an amount 6 times the molar weight of ethyl orthosilicate, adjusting the pH to 2.5, stirring for 2 hours, sealing and standing for 6 hours to obtain a hybr...

Embodiment 2

[0072] An embodiment of the present invention provides a method for preparing an organic-inorganic composite coating material, comprising the following steps:

[0073] Step 1, dissolving butyl titanate in absolute ethanol to obtain a butyl titanate solution with a mass concentration of 5wt%, and adding dropwise an acetic acid solution with a mass concentration of 18wt% in the butyl titanate solution, the dropping speed rate of 0.08mL / s, stirred for 1.5h, sealed and aged for 13h to obtain titanium dioxide sol; wherein butyl titanate and CH in acetic acid 3 The molar ratio of COOH is 0.1:1;

[0074] Step 2, dissolve ethyl orthosilicate in dehydrated alcohol, obtain the ethyl orthosilicate solution of mass concentration 30wt%, add the gamma-(methacryloyloxy ) Propyltrimethoxysilane, mixed evenly, adding water in an amount 6.5 times the molar weight of ethyl orthosilicate, adjusting the pH to 3, stirring for 2.5 hours, sealing and standing for 5.5 hours to obtain a hybrid silica ...

Embodiment 3

[0080] An embodiment of the present invention provides a method for preparing an organic-inorganic composite coating material, comprising the following steps:

[0081] Step 1, dissolving butyl titanate in absolute ethanol to obtain a butyl titanate solution with a mass concentration of 8wt%, and adding dropwise an acetic acid solution with a mass concentration of 18wt% in the butyl titanate solution, the dropping speed rate of 0.1mL / s, stirred for 2.5h, sealed and aged for 11h to obtain titanium dioxide sol; wherein butyl titanate and CH in acetic acid 3 The molar ratio of COOH is 0.2:1;

[0082] Step 2, dissolve ethyl orthosilicate in absolute ethanol to obtain a solution of ethyl orthosilicate with a mass concentration of 22wt%, and add γ-(methacryloyl Oxygen)propyltrimethoxysilane, mixed evenly, adding water with 5.5 times the molar weight of ethyl orthosilicate, adjusting the pH to 2, stirring for 1.5h, sealing and standing for 6.5h to obtain hybrid silica sol ;

[0083...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com