Smelting device for zinc alloy

A smelting equipment and zinc alloy technology, applied in the field of zinc alloy smelting equipment, can solve problems such as complex occupational hazard factors and serious pollutant discharge, achieve high degassing efficiency, high cleaning degree, high purity, and improve crystallizer structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

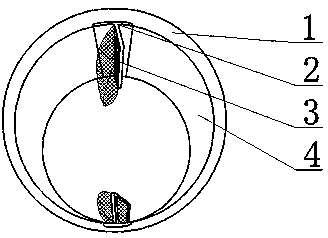

[0029] Such as figure 1 The smelting equipment for zinc alloy shown is composed of vacuum smelting equipment with built-in air passage and graphite stirring device and melting crucible 1, a protective atmosphere furnace, and a graphite crucible with mechanical stirring device, wherein the inner surface of melting crucible 1 The filter structure 2 is fixed in the area from the bottom to the top of the side 4 of the inner surface according to the structure of the wave wheel washing machine. The filter structure 2 is specifically composed of alumina ceramic wedges, alumina ceramic outer frame, and a primary coarse screen Net 5, and the online filter screen 3 made of carbon fiber ceramic composite material lined on the outer surface of the primary coarse screen 5;

[0030] Wherein the manufacture method of online filter screen cloth 3 is:

[0031] ①Material preparation: Prepare enough ammonia gas, enough propane, enough acrylonitrile, enough polyethylene oxide, enough pure water,...

Embodiment 2

[0043] The whole is consistent with Example 1, the difference is:

[0044] The basic salt used is specifically Cu 2 (OH) 2 CO 3 .

Embodiment 3

[0046] Such as image 3 The smelting equipment of a kind of zinc alloy shown is consistent with the embodiment 1 as a whole, the difference is that: the inner surface side 4 bottom to the top area of the inner surface of the smelting crucible 1 is fixed according to the structure of the wave wheel washing machine to set the filter net. Two filter structures 2 are provided, and the normal line of the opening end surface of the online filter screen 3 integrated on the two filter structures 2 faces the same direction and the two normal lines are parallel; the filter structure 2 is specifically composed of alumina ceramic wedges, alumina ceramic The outer frame, the primary coarse screen 5 made of alumina ceramics, and the online filter screen 3 made of carbon fiber ceramic composite material lined on the outer surface of the primary coarse screen 5 are formed.

[0047] The high aluminum-zinc alloy with 25%-28% aluminum mass fraction smelted in the present invention has a tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com