Concrete surface permeation consolidation type self-repairing coating and preparation method thereof

A concrete surface and self-repairing technology, which is applied in the field of coatings, can solve the problems of ignoring the multifunctional integration of concrete protective materials, and achieve excellent hydrophobicity, good weather resistance, and good low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

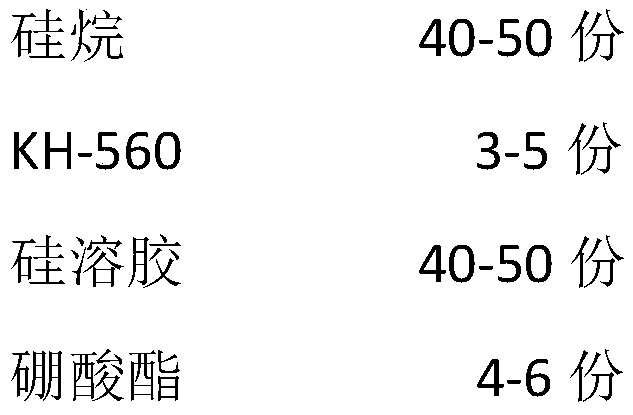

[0028] Raw material ratio of primer

[0029]

[0030] Preparation method of primer:

[0031] (1) Add silica sol into the reactor, then add methyltrimethoxysilane and KH-560 and stir at 30-40°C for 2-3h.

[0032] (2) Add triethyl borate to continue the reaction for 1-2h.

[0033] (3) Filtrate and pack to obtain the primer.

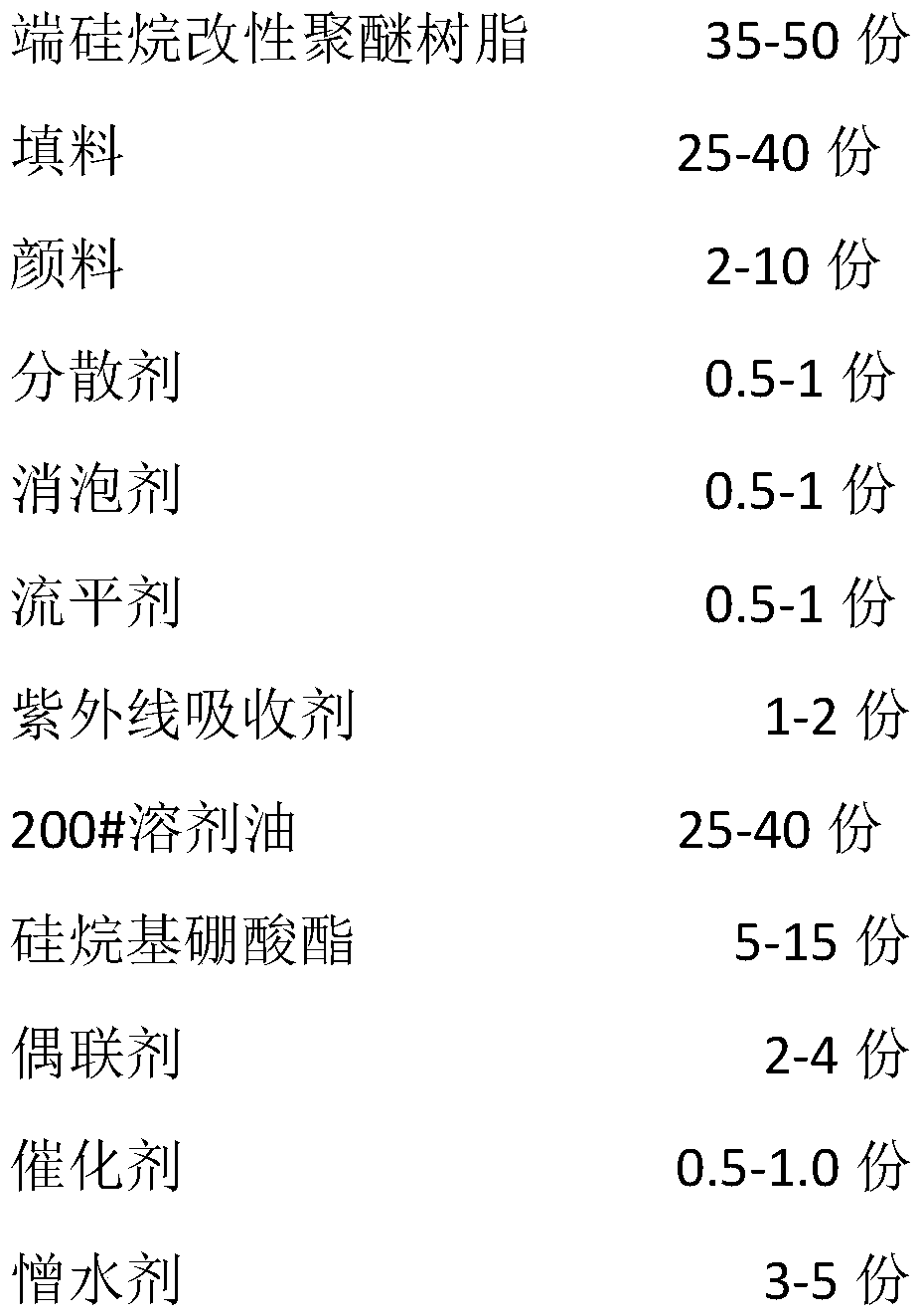

[0034] The formulation of the topcoat includes:

[0035]

[0036] Described topcoat preparation method is as follows:

[0037] Put the terminal silane modified polyether resin into the mixing tank, then add 200# solvent oil, titanium dioxide, mica powder, dispersant, defoamer, leveling agent, ultraviolet absorber, stir and disperse evenly, and grind to below 30μm , add silyl borate, KH-550, catalyst, water repellent, stir evenly to get top coat.

Embodiment 2

[0039] Raw material ratio of primer:

[0040]

[0041] Preparation method of primer:

[0042] (1) Add the silica sol into the reactor, then add methyltrimethoxysilane, propyltrimethoxysilane and KH-560 and stir at 30-40°C for 2-3h.

[0043] (2) Add tributyl borate to continue the reaction for 1-2h.

[0044] (3) Filtrate and pack to obtain the primer.

[0045] The formulation of the topcoat includes:

[0046]

[0047]

[0048] Described topcoat preparation method is as follows:

[0049] Put the terminal silane modified polyether resin into the mixing tank, then add 200# solvent oil, titanium dioxide, mica powder, dispersant, defoamer, leveling agent, ultraviolet absorber, stir and disperse evenly, and grind to below 30μm , add silyl borate, KH-550, catalyst, water repellent, stir evenly to get top coat.

Embodiment 3

[0051] Primer raw material ratio

[0052]

[0053] Preparation method of primer:

[0054] (1) Add silica sol into the reactor and then add methyltriethoxysilane, propyltrimethoxysilane and KH-560 and stir at 30-40°C for 2-3h.

[0055] (2) Trimethyl borate was added to continue the reaction for 1-2h.

[0056] (3) Filtration and packaging to obtain the primer.

[0057] The topcoat formulations include:

[0058]

[0059]

[0060] The preparation method of the topcoat;

[0061] Described topcoat preparation method is as follows:

[0062] Put the terminal silane modified polyether resin into the mixing tank, then add 200# solvent oil, titanium dioxide, mica powder, dispersant, defoamer, leveling agent, ultraviolet absorber, stir and disperse evenly, and grind to below 30μm , add silyl borate, KH-550, catalyst, water repellent, stir evenly to get top coat.

[0063] The performance test data of the multi-functional concrete self-repairing coating prepared in implementa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com