Preparation method and product of shape adaptive fast response soft heater

A fast-response heater technology, applied in the direction of ohmic resistance heating, ohmic resistance heating components, electric heating devices, etc., can solve the problem that the heater cannot heat three-dimensional curved surface objects with large deformation and is difficult to apply, and achieves fast speed and high response speed Fast, good conductivity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] refer to figure 1 As shown in (a)-(i), the present invention provides a method for preparing a shape-adaptive fast-response soft heater, comprising the following steps:

[0040] (1) if figure 1 As shown in (a), the hard substrate 1 is cleaned with acetone, isopropanol and deionized water in sequence, and then dried with nitrogen. Preferably, the hard substrate 1 is a monocrystalline silicon wafer, polycrystalline silicon wafer, epitaxial wafer, quartz wafer or glass wafer, with a flat and smooth surface.

[0041] (2) if figure 1 As shown in (b), a sacrificial layer 2 cured by polyvinyl alcohol aqueous solution is prepared on the hard substrate 1 . Specifically, the polyvinyl alcohol aqueous solution is first configured, then the polyvinyl alcohol aqueous solution is spin-coated on the hard substrate 1, and then heated to solidify the polyvinyl alcohol aqueous solution on the hard substrate 1 to form a film, and the cured film forms the sacrificial layer 2 . More sp...

Embodiment 1

[0056] a. Hard substrate 1 selects a 4-inch monocrystalline silicon wafer, cleans its polished surface with acetone, isopropanol and deionized water in sequence and blows it dry with nitrogen, then spin-coats the 10% polyvinyl alcohol aqueous solution configured in the above-mentioned scheme two on top. Afterwards, the silicon wafer was heated on a hot plate at a temperature of 80° C. for 15 minutes, so that the water was heated to evaporate, and the polyvinyl alcohol was solidified to form a film, and the preparation of the sacrificial layer 2 was completed.

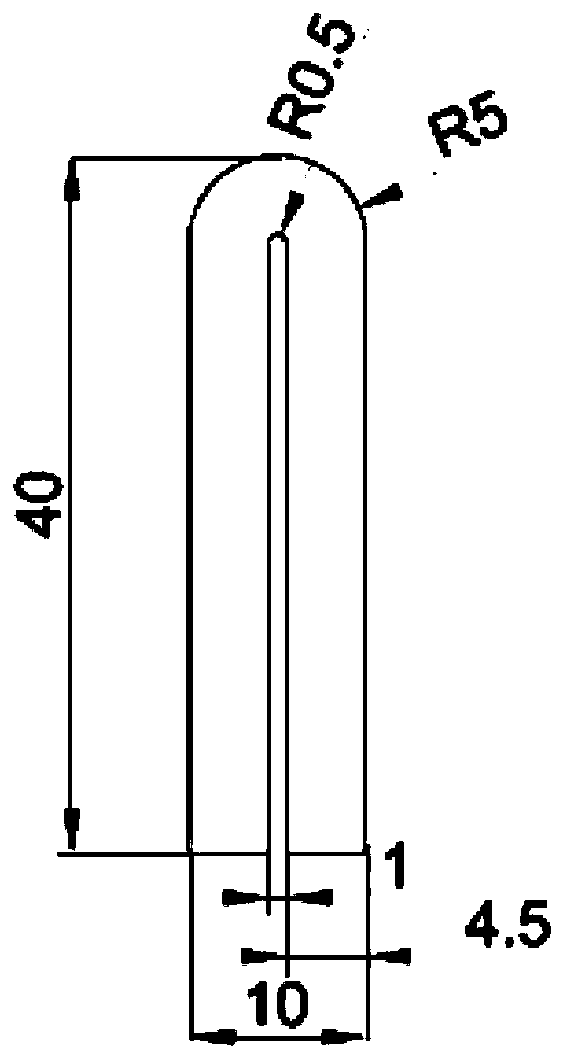

[0057] b. Put the hard substrate 1 on the stage of the manual screen printing machine, make the screen plate parallel to the hard substrate 2 and keep a distance of 5 mm. The stencil adopts such as figure 2 The pattern shown is U-shaped, and then the hard substrate 1 is heated to cure the conductive material 3 to form a patterned conductive layer 4 . The conductive layer 4 has a thickness of 35 microns.

[0058]c. S...

Embodiment 2

[0064] a. The selection of the hard substrate 1 and the preparation of the sacrificial layer 2 are the same as in Example 1.

[0065] b. Put the hard substrate 1 on the stage of the manual screen printing machine, make the screen plate parallel to the hard substrate 2 and maintain a distance of 8 mm. The stencil adopts such as image 3 The pattern shown, ie parallelogram, is then heated to hard substrate 1 to cure conductive material 3 to form patterned conductive layer 4 . The conductive layer 4 has a thickness of 25 microns.

[0066] c. Spin-coat polydimethylsiloxane on the sacrificial layer 2 as the flexible substrate 5 of the shape-adaptive fast-response soft heater, the spin-coating speed is 800 rpm, and the spin-coating time is 3 minutes, so that It covers the patterned conductive layer 4 and is then heated to cure it. The curing temperature is 80° C., and the curing time is 1 hour. Under this condition, the flexible substrate 5 has a thickness of 135 micrometers.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com