Compound lactic acid bacterium preparation and application thereof in preparing feed additive

A technology for compounding lactic acid bacteria and feed additives, which is applied in the field of microorganisms, can solve the problems that the fermentation level activity needs to be improved, the dry product is rapidly deactivated, and the use effect is not ideal, so as to achieve the effects of promoting the growth of piglets, improving the survival rate, and reducing the loss of activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Screening of Lactobacillus casei F209 strain:

[0033] 1. Preparation of culture medium:

[0034] BCP medium: peptone 5g; yeast extract 3g; lactose 5g; agar 20g; 0.5% bromocresol purple 10ml; distilled water 1000ml; pH value 6.8-7.0.

[0035] MRS liquid medium: glucose 20g / L; peptone 10g / L; yeast extract 5g / L; beef powder 10g / L; diammonium citrate 2g / L; sodium acetate 5g / L; Tween 80 1g / L; Dipotassium hydrogen phosphate 2g / L.

[0036] YG liquid medium: glucose 20g / L; yeast extract powder 5g / L.

[0037] The solid medium was added with 1.5% agar on the basis of the liquid medium, and all the medium was sterilized at 115°C for 20 minutes.

[0038] 2. Screening: Take 5g of kimchi samples and place them in 200ml MRS liquid medium for 18 hours, then take 1ml of culture medium and apply gradient dilution to BCP plate. After incubating at 37℃ for 48 hours, select the typical lactic acid bacteria colony morphology (the colony turns yellow around ) Colonies were streaked and cultured. A to...

Embodiment 2

[0043] Probiotic performance test of Lactobacillus casei F209:

[0044] Take the Lactobacillus casei F209 seed solution that has grown to the late logarithmic stage and centrifuge it, wash it twice with 0.9% saline, and resuspend it at 10 8 The amount of CFU / ml was inoculated into artificial gastric juice with pH 2.5, incubated in a 37°C water bath, and sampled and diluted on YPD plates every 1 hour to determine the number of viable bacteria.

[0045] The results showed that when the Lactobacillus casei F209 tolerated the simulated gastric juice with pH 2.5 for 1 hour, the survival rate was 75.25%; at 2 hours, the survival rate was 37.35%; at 3 hours, the survival rate was 16.65%.

[0046] Take the Lactobacillus casei F209 seed solution that has grown to the late logarithmic stage and centrifuge it, wash it twice with 0.9% saline, and resuspend it at 10 8 The amount of CFU / mL was inoculated into the artificial intestinal fluid, incubated in a 37°C water bath for 8 hours, sampled and d...

Embodiment 3

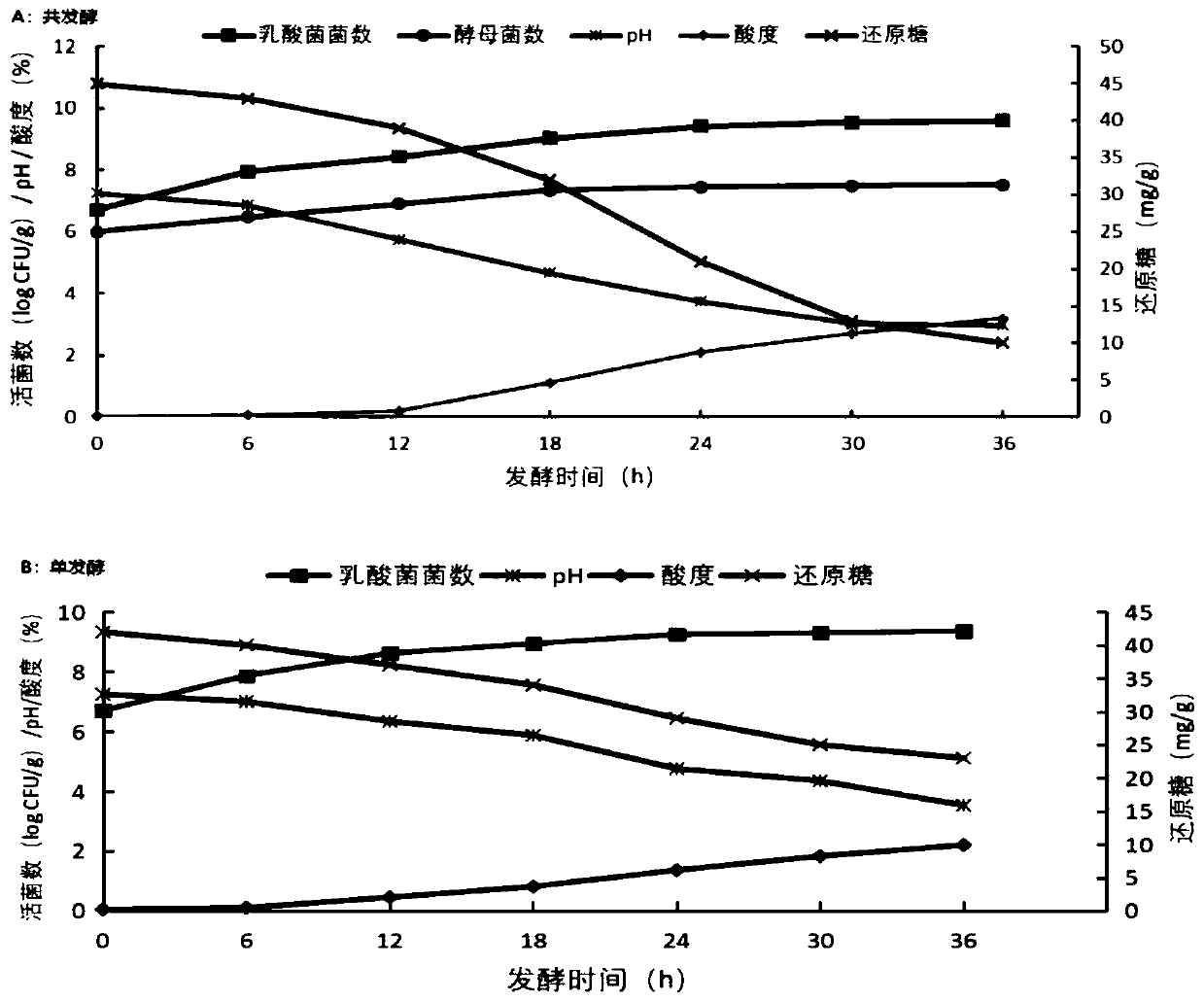

[0053] Single fermentation of Lactobacillus casei F209 and co-fermentation with Saccharomyces boulardii SH94 (CCTCC NO: M2014211):

[0054] Fermentation medium preparation: 20g wheat and 40g corn crushed through 80 mesh sieve, add 1000ml of water, add 0.1g glucoamylase (enzyme activity 200,000 U / g) and 0.01g pullulanase (enzyme activity 2000U / g) ) And keep it for 60min, then add 10g yeast extract and 0.5g sodium hydroxide and heat to 115°C for 20min sterilization.

[0055] Seed solution: YPD medium (1% yeast extract, 2% peptone, 2% glucose) sterilized at 115°C for 20 minutes and then cooled to room temperature. After inserting 1% lactic acid bacteria, let it stand at 37°C for 24 hours to obtain lactic acid bacteria seed solution. After 5% yeasts were cultured at 30°C and 150rpm for 24 hours to obtain yeast seed liquid.

[0056] A 5L fermenter was used for the experiment. 3L of fermentation medium was prepared according to the above formula, the temperature of the fermentation proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com