Bacillus sphaericus with high yield and high-temperature xylanase resistance and application thereof

A technology of Bacillus sphaericus and xylanase, applied in the field of applied microorganisms, can solve the problems that hinder the development of xylanase application and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Screening and cultivation of high-yield and thermostable xylanase strains

[0022] Enrichment medium: NaNO 3 0.5g, K 2 HPO 4 l g, MgSO 4 ·7H 2 O0.5g, KCl0.5g, FeSO 4 ·7H 2 O0.005g, distilled water 1000mL, pH natural, sterilized at 121°C for 20min.

[0023] Screening medium: peptone 10g, yeast extract 3g, NaCl 5g, xylan 4g, agar powder 15g,

[0024] Distilled water 1000mL, pH8.0, sterilized at 121°C for 20min.

[0025] Fermentation medium: peptone 10g, yeast extract 3g, NaCl 5g, xylan 4g, distilled water 1000mL, pH natural, sterilized at 121°C for 20min.

[0026] LB medium: 10g of peptone, 5g of yeast extract, 10g of NaCl, 20g of agar, dissolved in 1000mL of distilled water, pH 7.0-7.2, sterilized at 121°C for 20min.

[0027] Collect several 5g samples from different positions of straw compost located around the biomethane production workshop of Nanjing University of Technology, put them in 250mL Erlenmeyer flasks, add 50mL sterile water, and incubate ...

Embodiment 2

[0028] The biological identification of embodiment 2 screening bacterial strains

[0029] 1. Morphological identification of strains

[0030] The isolated and purified strains were inoculated on solid LB medium and cultured at 37°C for 24 hours to observe the plate colony morphology of the strains. Such as figure 1 , strain Xyn-1, after growing on solid LB medium, the colony diameter is 0.6cm, the shape is a regular protrusion, which can form endophytic spores, the shape is round, the medium is white opaque colony, the surface is smooth, and the edge of the colony is regular .

[0031] 2. Molecular identification of strains

[0032]The strains of the screened bacteria were identified based on the bacterial 16S rDNA sequence library of the NCBI database. The DNA of the strain was extracted using a bacterial genome extraction kit, and PCR amplification was carried out using bacterial 16S rDNA universal primers. The PCR reaction system is (25 μL): template DNA 10ng, 10×PCR b...

Embodiment 3

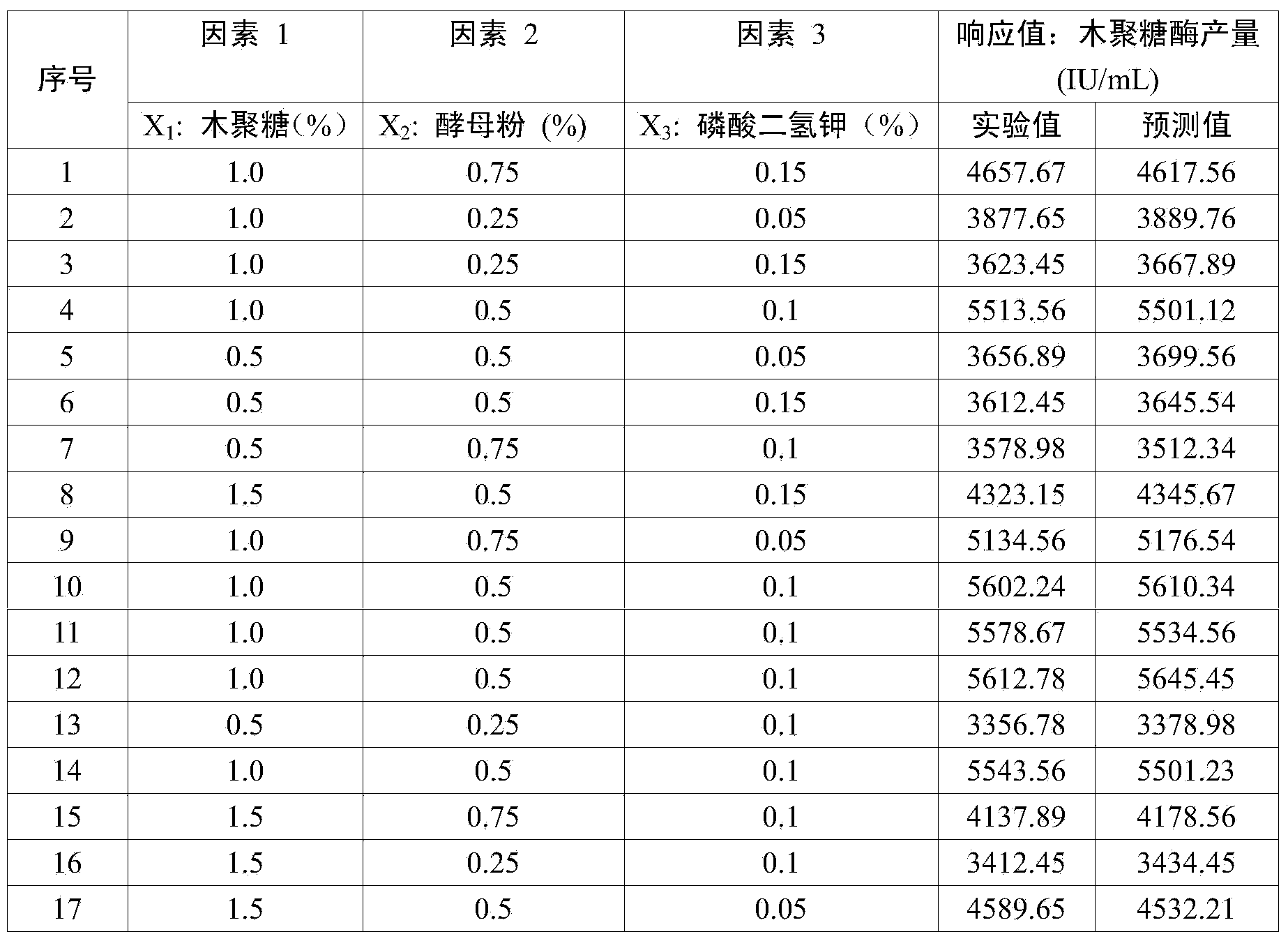

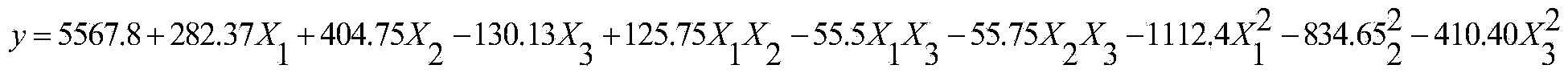

[0034] The optimization of embodiment 3 fermentation culture conditions

[0035] The culture conditions of strain Xyn-1 were optimized by single factor analysis method, and the best culture conditions were determined: the amount of culture medium was 25mL / 250mL conical flask, the culture temperature was 45°C, the rotation speed of shaker flask was 200r / min, and the concentration of bacterial suspension was 5 ×10 6 Individual / mL, the inoculum volume per bottle is 1.0mL, the initial pH is 7.0, and the fermentation time is 72 hours. Optimization of medium composition:

[0036] The 9 factors related to the medium of Xyn-1 enzyme production were determined by single factor analysis. The Plackett-Burman design was used to screen the important influencing factors of enzyme production, and the design with the number of trials N=12 was selected to control the lactose, maltose, xylan, yeast powder, peptone, sodium chloride, magnesium sulfate, ammonium sulfate and phosphoric acid in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com