Cylinder sleeve and preparation method thereof

A cylinder liner and blank technology, applied in the field of cylinder liner and its preparation, can solve the problems of affecting the service life of the engine, increasing the oil consumption of lubricating oil, poor heat conduction of the cylinder liner, etc., to reduce the friction coefficient, improve wear resistance, and good lubricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

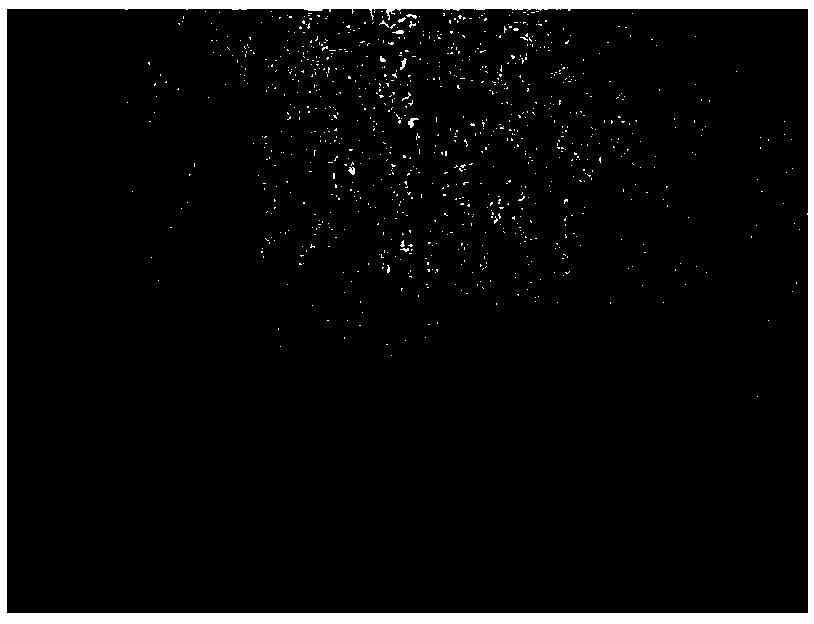

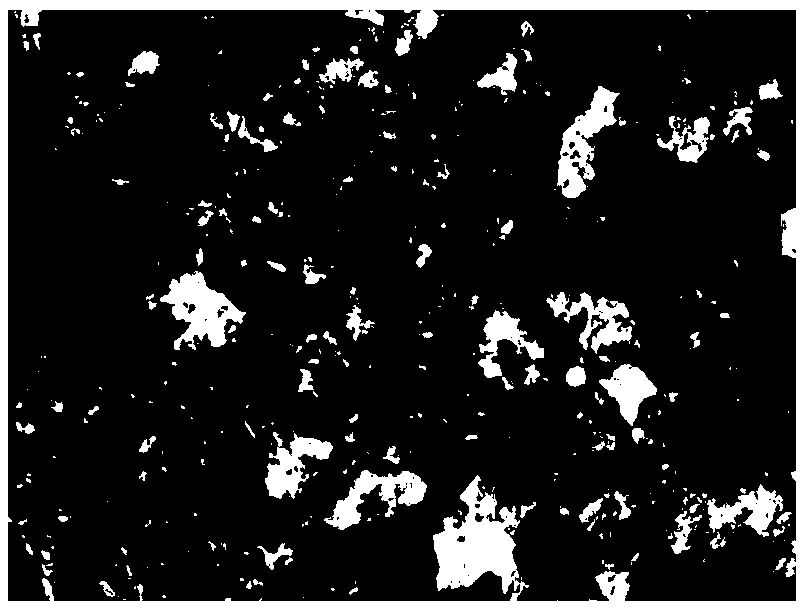

Image

Examples

Embodiment 1

[0045] Mix carbon, silicon, phosphorus, sulfur, manganese, copper, lead and iron, and accurately weigh each raw material for melting. The melting temperature is 1460-1480°C. After melting, stand at high temperature for 15 minutes to make copper, manganese and other alloying elements Fully dissolved in the alloy liquid.

[0046] The above alloy liquid is prepared by a water-cooled metal mold centrifugal casting process to obtain a blank, which is poured using a single-station centrifugal pouring machine. Primary inoculation treatment (inoculant consumption 0.6wt%); then transfer to the fire pouring spoon for secondary inoculation, the bottom of the fire pouring spoon is placed with silicon strontium inoculant (inoculant consumption 0.2wt%), pouring after inoculation is completed, pouring The temperature is 1430°C-1450°C, the speed of the pouring machine is 1200 rpm, the thickness of the mold coating is 0.6mm, the mold preheating temperature is 260°C, the water supply time is 19...

Embodiment 2

[0063] Mix carbon, silicon, phosphorus, sulfur, manganese, copper, lead and iron, and accurately weigh each raw material for melting. The melting temperature is 1450-1470°C. After melting, stand at high temperature for 15 minutes to make copper, manganese and other alloying elements Fully dissolved in the alloy liquid.

[0064] The above-mentioned alloy liquid is prepared by a water-cooled metal mold centrifugal casting process to obtain a blank; a single-station centrifugal pouring machine is used for pouring, and the alloy liquid after standing is first poured into a large ladle, and a silicon-barium inoculant is placed at the bottom of the large ladle. Primary inoculation treatment (inoculant dosage 0.6wt%); then transfer to the fire ladle for secondary inoculation, place silicon strontium inoculant (inoculant dosage 0.2wt%) at the bottom of the fire ladle, and then pour, pouring temperature 1430°C ~1450°C, pouring machine speed 1200 rpm, mold coating thickness 0.6mm, mold ...

Embodiment 3

[0076] Mix carbon, silicon, phosphorus, sulfur, manganese, copper, lead and iron, and accurately weigh each raw material for melting. The melting temperature is 1450-1470°C. After melting, stand at high temperature for 15 minutes to make copper, manganese and other alloying elements Fully dissolved in the alloy liquid.

[0077] The above-mentioned alloy liquid is prepared by a water-cooled metal mold centrifugal casting process to obtain a blank; a single-station centrifugal pouring machine is used for pouring, and the alloy liquid after standing is first poured into a large ladle, and a silicon-barium inoculant is placed at the bottom of the large ladle. Primary inoculation treatment (inoculant dosage 0.6wt%); then transfer to the fire ladle for secondary inoculation, place silicon strontium inoculant (inoculant dosage 0.2wt%) at the bottom of the fire ladle, and then pour, pouring temperature 1430°C ~1450°C, pouring machine speed 1200 rpm, mold coating thickness 0.6mm, mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com