Emulsified asphalt and brushing type rubber asphalt waterproof coating, and preparation methods thereof

A technology of emulsified asphalt and waterproof coatings, applied in the field of coatings, can solve the problems of affecting appearance and difficult to reuse, and achieve the effects of saving resources, good stability and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Components of the emulsified asphalt: 62kg of 70# petroleum asphalt, 1.5kg of alkyl alcohol polyoxyethylene ammonium sulfate, 0.15kg of sodium hydroxide, 0.5kg of hydroxymethyl cellulose, and 35.85kg of deionized water.

[0040] Preparation process of emulsified asphalt: Weigh the formulated amount of petroleum asphalt and heat it to 130°C;

[0041] Prepare an emulsifier solution, add the formula amount of alkyl alcohol polyoxyethylene (3) ammonium sulfate, sodium hydroxide, and hydroxymethyl fiber to the formula amount of deionized water, stir evenly until completely dissolved, and preheat to 65 ° C ~ 70°C;

[0042] The heated petroleum asphalt and emulsifier solution are simultaneously added to the colloid mill of an emulsifier for emulsification, cooled to room temperature, and filtered to obtain the emulsified asphalt.

[0043] Components of brushing type rubber asphalt waterproof coating: 62kg of emulsified asphalt mentioned above, 28kg of neutral carboxylic acid ...

Embodiment 2

[0057] Components of emulsified asphalt: 70# petroleum asphalt 30kg, 90# petroleum asphalt 30kg, alkyl alcohol polyoxyethylene (3) sodium sulfate 0.5kg, alkyl alcohol polyoxyethylene (2) sodium sulfate 0.5kg, sodium hydroxide 0.20 kg, hydroxyethyl cellulose 0.5kg, deionized water 38.3kg.

[0058] The emulsified asphalt preparation process refers to Example 1, and will not be repeated here.

[0059] Components of brushing rubber asphalt waterproof coating: 60kg of the emulsified asphalt mentioned above, 23kg of neutral carboxylic acid modified chloroprene latex, 7kg of styrene-butadiene latex, 6.5kg of filler, 0.5kg of other additives, and 3.15kg of deionized water.

[0060] Specifically, other auxiliary agents include 0.1Kg of dispersant, 0.05Kg of wetting agent, 0.04Kg of defoamer, 0.08Kg of antioxidant, 0.03Kg of pH regulator, and 0.05Kg of thickener.

[0061] The preparation process of the brush-type rubber asphalt waterproof coating refers to Example 1, and will not be re...

Embodiment 3

[0066] Components of the emulsified asphalt: 50kg of 70# petroleum asphalt, 13kg of 90# petroleum asphalt, 2.0kg of alkyl alcohol polyoxyethylene (3) sodium sulfate, 0.15kg of sodium hydroxide, 0.5kg of sodium bentonite, and 36.35kg of deionized water.

[0067] The emulsified asphalt preparation process refers to Example 1, and will not be repeated here.

[0068] Components of brushing rubber asphalt waterproof coating: 50kg of emulsified asphalt mentioned above, 25kg of neutral carboxylic acid modified chloroprene latex, 5kg of natural latex, 13kg of filler, 0.5kg of other additives, 6.3kg of deionized water.

[0069] Specifically, other auxiliary agents include 0.2Kg of dispersant, 0.1Kg of wetting agent, 0.08Kg of defoamer, 0.16Kg of antioxidant, 0.06Kg of pH regulator, and 0.1Kg of thickener.

[0070] The preparation process of the brush-type rubber asphalt waterproof coating refers to Example 1, and will not be repeated here.

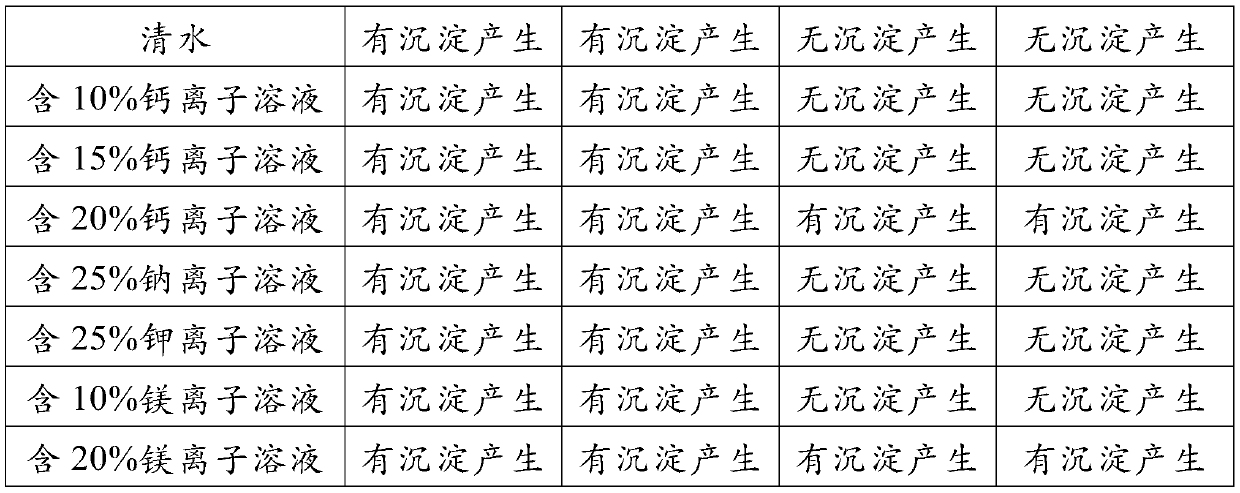

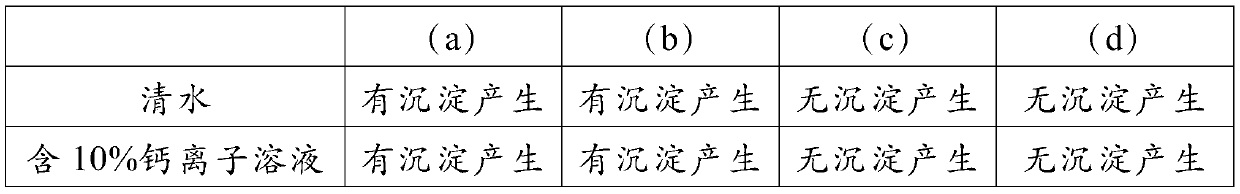

[0071] Add conventional anionic emulsified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com