Anti-oxidation high-hardness wear-resistant coating on surface of titanium alloy and preparation method

A wear-resistant coating and anti-oxidation technology, which is applied in the coating process and coating of metal materials, can solve the problems of difficult forming control, poor deformation coordination ability and cumbersome spraying steps of the preset powder method, so as to reduce the finishing process The effect of reducing workload, improving wear resistance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]The invention also discloses a method for preparing an anti-oxidation high-hard wear-resistant coating on the surface of a titanium alloy, which comprises the following steps:

[0039] S1. Detect the purchased Ti6Al4V substrate and cladding powder to ensure the cladding quality;

[0040] S2. Perform pretreatment on the base material to be clad;

[0041] S3, pretreating the cladding powder;

[0042] S4. Using a coaxial powder feeding laser, cladding powder is clad on the test block to be clad.

[0043] In S1, first use absolute ethanol to clean the stains on the surface of the titanium alloy plate to be processed, and cut the substrate to be clad into 100×100×10mm cladding test pieces with an electric spark cutting machine;

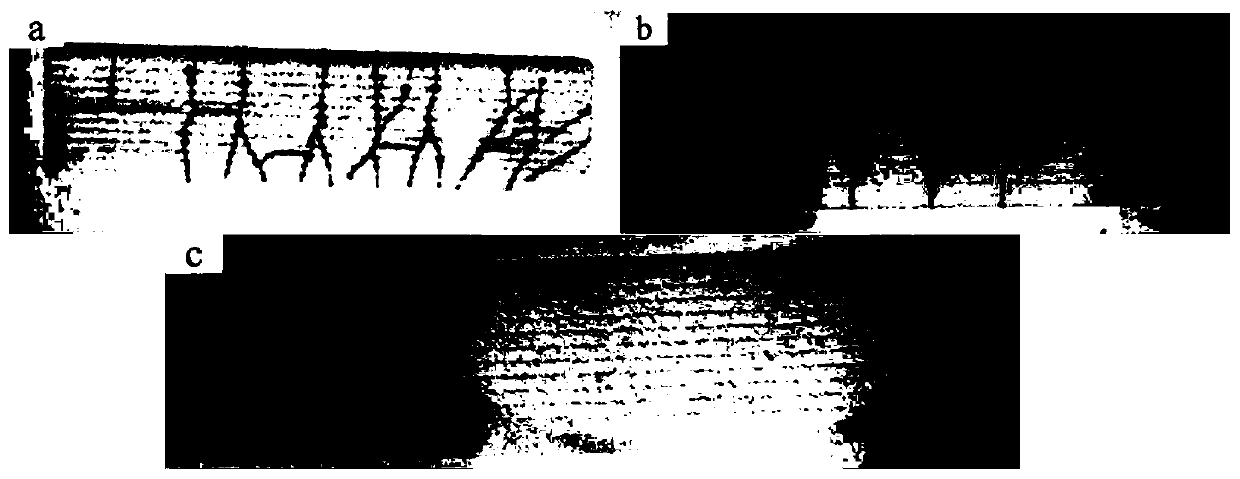

[0044] In S2, the cladding test block is pre-treated, specifically: sandblasting the cladding test block to remove the surface oxide layer and dirt, and at the same time, it can also improve the roughness of the cladding test block and increase the...

Embodiment 1

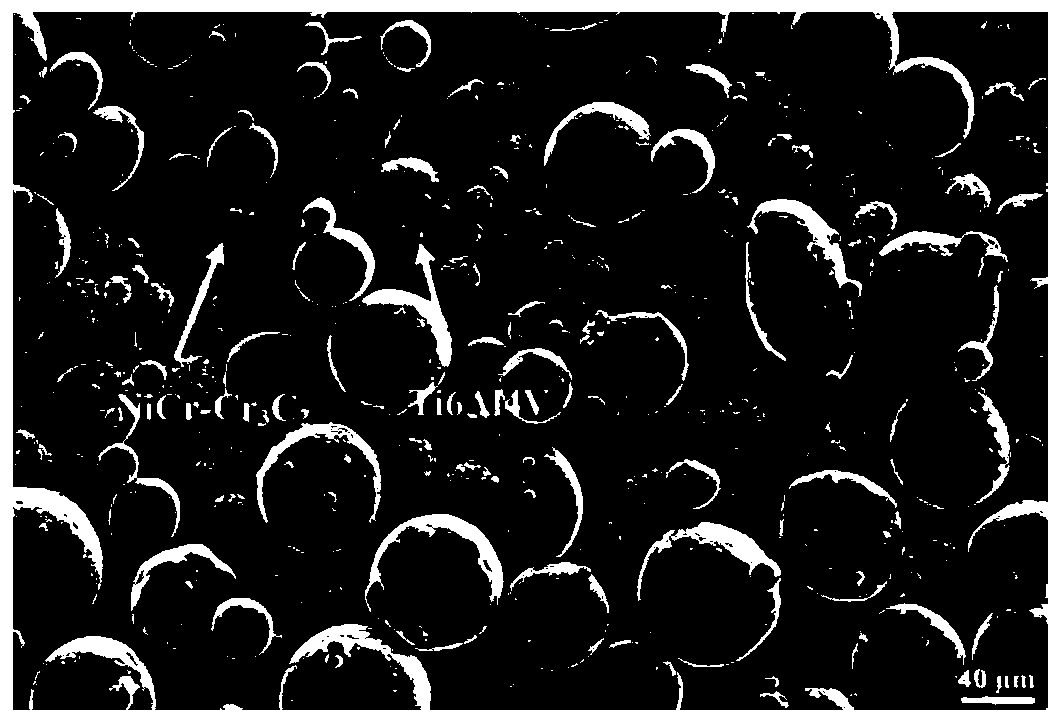

[0048] The specific scheme of this case is 75wt%TC4+25wt%NiCr-Cr 3 C 2 , laser power 700W according to the above steps to prepare laser cladding coating.

Embodiment 2

[0050] The specific scheme of this case is 75wt%TC4+25wt%NiCr-Cr 3 C 2 , laser power 900W according to the above steps to prepare laser cladding coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com