An improvement method of an extra-high water head fixed wheel gate and the fixed wheel gate

A fixed-wheel gate and high water head technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of uneven bottom compression and easy bending, gates are prone to vibration, and water leakage, etc., to reduce post-welding defects Difficulty, reduce welding workload, and prevent water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

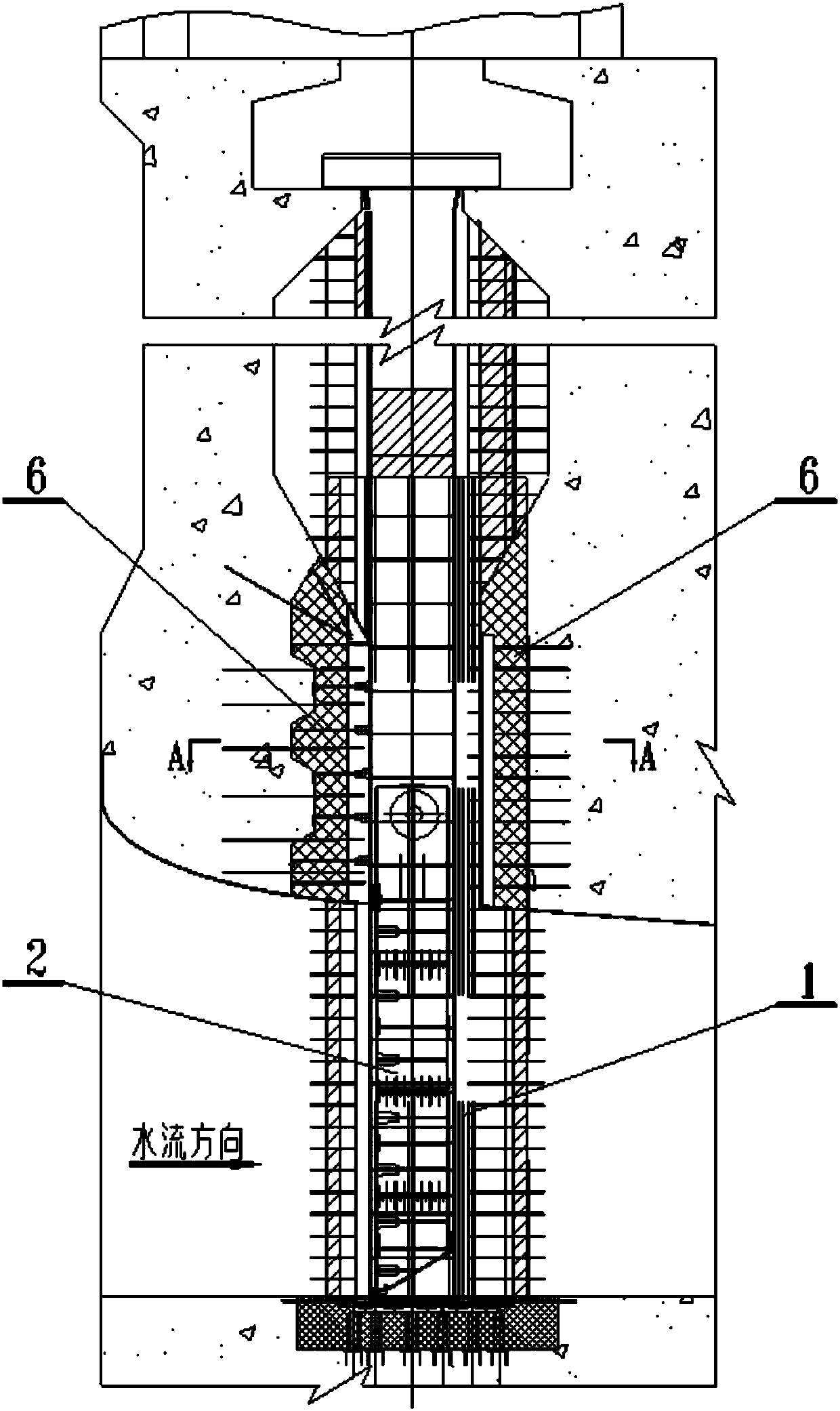

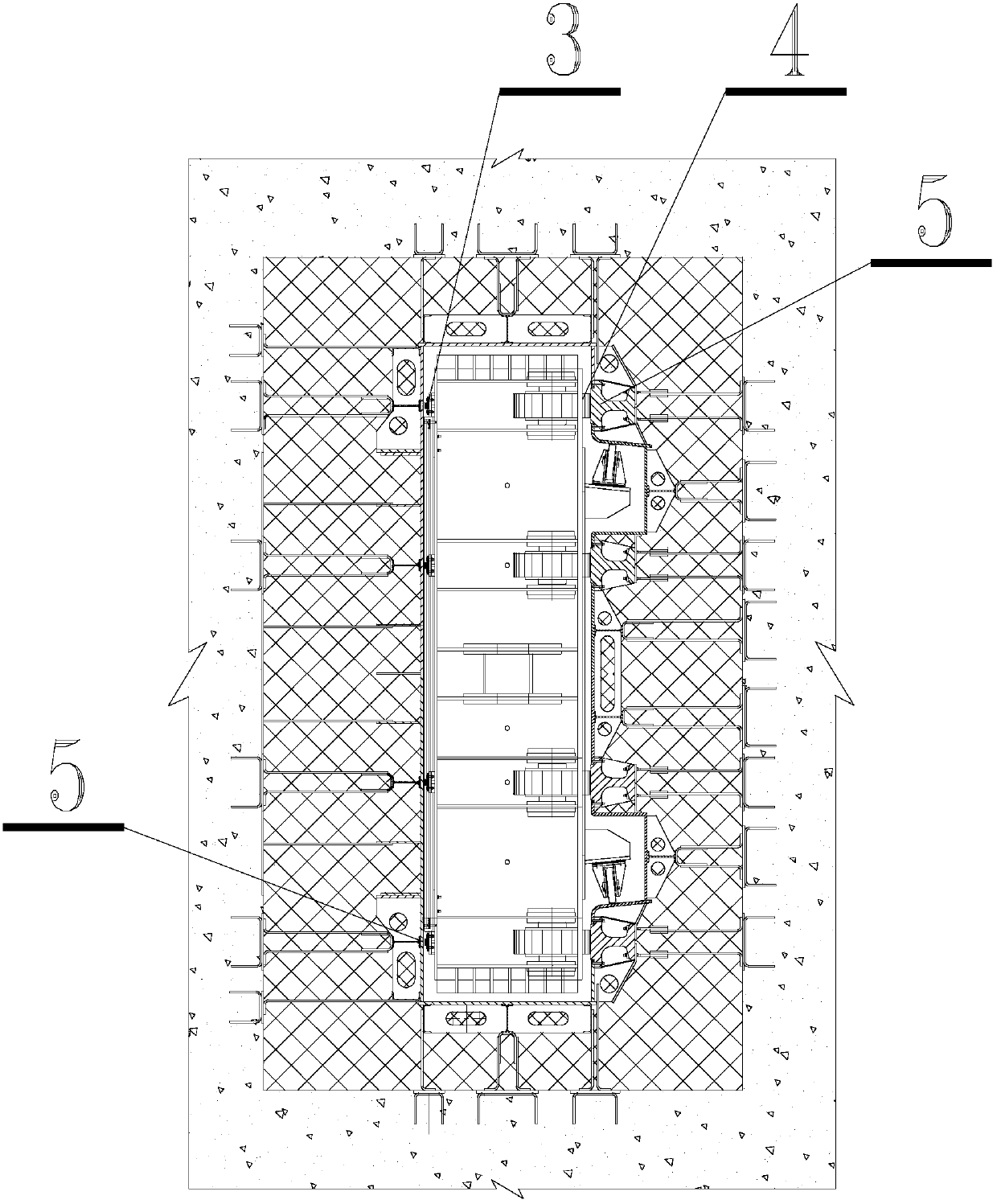

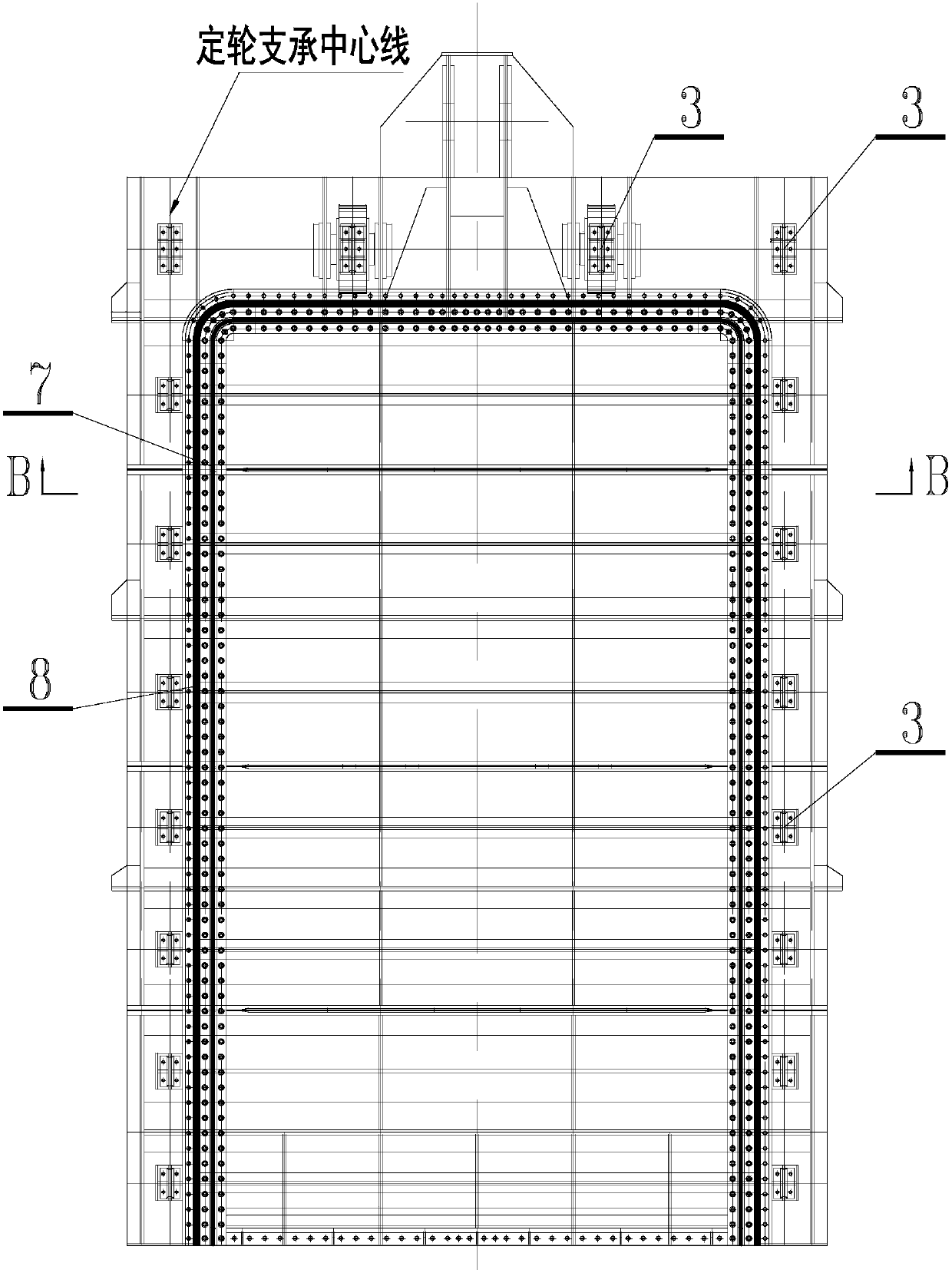

[0033] In this example, fixed wheel gate 2 is set in door slot 1. The two sides and the top of the water-facing surface of the fixed-wheel gate 2 are provided with reverse support sliders 3, and the two sides and the top of the back-water surface are provided with positive support fixed-wheel devices 4; the rails 5 corresponding to the forward and reverse support positions are provided in the gate slot 1 And the upper and lower reaches are provided with high parapet walls 6; a pressurized "mountain" type water seal 7 and a P-shaped water seal 8 are arranged on the upstream of the gate 2 from the inside to the outside; the gate 2 is divided into sections on the main beam 9; Beam 9 is composed of two split main beams 10 made symmetrically up and down through bolts 11; split main beam 10 is composed of front flange plate 12, web plate 13 and rear flange plate 14 made symmetrically from left to right; web plate 13 is composed of side column connecting plate 15, middle connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com