Preparing method for HDPE pipe

A preparation step and powder technology, applied in the field of HDPE pipe preparation, can solve the problems of poor toughness of HDPE pipes, easy corrosion of conveying pipes, inability to bend greatly, etc., and achieve the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

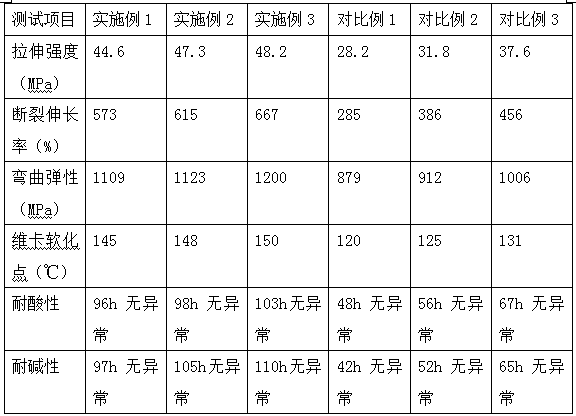

Examples

Embodiment 1

[0031] The release agent is: silicone oil

[0032] Preparation of mud:

[0033] In parts by weight, add 70 parts of kaolin, 20 parts of alumina, 10 parts of titanium dioxide, and 20 parts of aluminum phosphate to 400 parts of water, stir and disperse to form a suspension slurry, and add a phosphoric acid solution with a mass fraction of 20% to the suspension slurry Adjust the pH value of the suspended slurry to 5, heat up to 50°C, and keep it warm for 10 hours to obtain slurry;

[0034] Preparation of silica-alumina reinforced fibers:

[0035] 30 parts of nano-silica airgel, 30 parts of montmorillonite, and 200 parts of water are mixed to obtain nano-silica airgel slurry, and then the above-mentioned mud and nano-silica airgel slurry are 4 in volume ratio: 1 Mix, put into the crucible in the muffle furnace, heat to 700°C, preheat for 40 minutes, then raise the temperature to 1300°C, keep warm for 30 minutes to obtain molten material liquid, and obtain silicon-aluminum reinfo...

Embodiment 2

[0045] The release agent is: polyethylene glycol

[0046] Preparation of mud:

[0047] In parts by weight, add 75 parts of kaolin, 25 parts of alumina, 12.5 parts of titanium dioxide, and 21 parts of aluminum phosphate to 450 parts of water, stir and disperse to form a suspension slurry, and add a phosphoric acid solution with a mass fraction of 20% to the suspension slurry Adjust the pH value of the suspended slurry to 5.5, heat up to 55°C, and keep it warm for 12.5 hours to obtain slurry;

[0048] Preparation of silica-alumina reinforced fibers:

[0049] 40 parts of nano-silica airgel, 35 parts of montmorillonite, and 250 parts of water are mixed to obtain nano-silica airgel slurry, and then the above-mentioned mud and nano-silica airgel slurry are 4 in volume ratio: 1 Mix, put into a crucible in a muffle furnace, heat to 750°C, preheat for 45 minutes, then raise the temperature to 1325°C, keep warm for 32.5 minutes to obtain molten material liquid, and obtain silicon-alum...

Embodiment 3

[0059] The release agent is: low molecular weight polyethylene

[0060] Preparation of mud:

[0061]In parts by weight, add 80 parts of kaolin, 30 parts of alumina, 15 parts of titanium dioxide, and 22 parts of aluminum phosphate to 500 parts of water, stir and disperse to form a suspension slurry, and add a phosphoric acid solution with a mass fraction of 20% to the suspension slurry Adjust the pH value of the suspended slurry to 6, heat up to 60°C, and keep the temperature for 15 hours to obtain the slurry;

[0062] Preparation of silica-alumina reinforced fibers:

[0063] 50 parts of nano-silica airgel, 40 parts of montmorillonite, and 300 parts of water are mixed to obtain nano-silica airgel slurry, and then the above-mentioned mud and nano-silica airgel slurry are in a volume ratio of 4: 1 Mix, put into the crucible in the muffle furnace, heat to 800°C, preheat for 50 minutes, then raise the temperature to 1350°C, keep warm for 35 minutes to obtain molten material liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com