Preparation and application of marine biological waste oyster shell-supported palladium catalyst

A technology of a palladium catalyst and an oyster shell is applied in the preparation of heterogeneous palladium catalysts and the field of preparation of marine biomass-supported palladium catalysts, and can solve the problems of environmental pollution, high price of homogeneous palladium catalysts, etc., and achieves a wide range of materials and simple processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

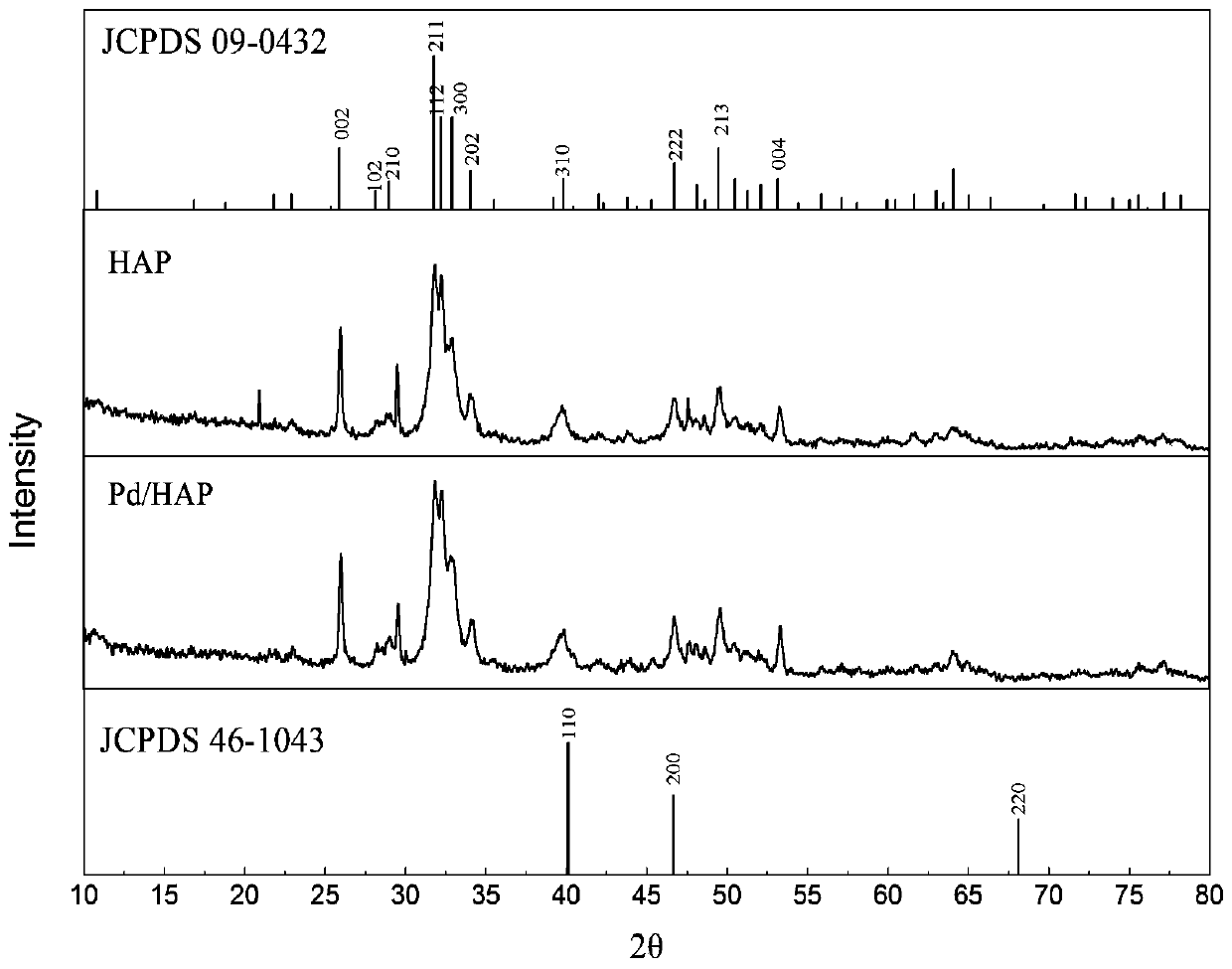

[0047] Step 1: Preparation of nano-hydroxyapatite (HAP)

[0048] (1) Fresh oyster shells are cleaned and air-dried naturally, add an appropriate amount of 10% sodium hydroxide solution, and heat at 95°C for 5 hours to fully remove protein;

[0049] (2) Take out the oyster shell, rinse it repeatedly with water, dry it at 100°C, crush it, and pass it through a 100-mesh sieve; the obtained powder is dried at 70-100°C for 24 hours;

[0050] (3) Take oyster shells, (NH4)2HPO4, and cetyltrimethylammonium bromide and add them to the inner tank of the reactor (Ca / P molar ratio n(CaCO3):n((NH4)2HPO4) is 5:6) , adding an appropriate amount of deionized water, adjusting the pH to 6 with phosphoric acid, stirring magnetically at room temperature for 1 hour, sealing the reaction vessel, and stirring and reacting at 140°C for 24 hours;

[0051] (4) After the reaction kettle is cooled to room temperature, centrifuge to obtain a precipitate, and centrifuge and wash the precipitate with deion...

Embodiment 2

[0066] Step 1: Preparation of nano-hydroxyapatite (HAP)

[0067] (1) Fresh oyster shells are cleaned and air-dried naturally, soaked in 5% sodium hypochlorite solution for 1 day to remove protein;

[0068] (2) Take out the oyster shell, rinse it repeatedly with water, dry it at 100°C, crush it, and pass it through a 100-mesh sieve; the obtained powder is dried at 70-100°C for 24 hours;

[0069] (3) Add oyster shells, (NH4)2HPO4, and cetyltrimethylammonium bromide to the inner tank of the reactor (Ca / P molar ratio n(CaCO3):n((NH4)2HPO4) is 1:1) , adding an appropriate amount of deionized water, adjusting the pH to 6 with phosphoric acid, stirring magnetically at room temperature for 1 hour, sealing the reaction vessel, and stirring and reacting at 140°C for 24 hours;

[0070] (4) After the reaction kettle is cooled to room temperature, centrifuge to obtain a precipitate, and centrifuge and wash the precipitate with deionized water for 3 to 6 times until no carbonate ion is det...

Embodiment 3

[0084] Step 1: Preparation of nano-hydroxyapatite (HAP)

[0085] (1) Fresh oyster shells are cleaned and air-dried naturally, add an appropriate amount of 10% sodium hydroxide solution, and heat at 95°C for 5 hours to fully remove protein;

[0086] (2) Take out the oyster shell, rinse it repeatedly with water, dry it at 100°C, crush it, and pass it through a 100-mesh sieve; the obtained powder is dried at 70-100°C for 24 hours;

[0087](3) Take oyster shells, (NH4)2HPO4, and cetyltrimethylammonium bromide and add them to the inner tank of the reactor (Ca / P molar ratio n(CaCO3):n((NH4)2HPO4) is 5:6) , adding an appropriate amount of deionized water, adjusting the pH to 6 with phosphoric acid, stirring magnetically at room temperature for 1 hour, sealing the reaction vessel, and stirring and reacting at 140°C for 24 hours;

[0088] (4) After the reaction kettle is cooled to room temperature, centrifuge to obtain a precipitate, and centrifuge and wash the precipitate with deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com