A kind of functional uio-66/polyurethane composite grouting reinforcing agent and preparation method thereof

A technology of UIO-66 and UIO-66-NH2, which is applied in the field of functional UIO-66/polyurethane composite grouting reinforcement material and its preparation, can solve the problems restricting industrial application, achieve excellent gas adsorption and separation performance, and can structure Design, topology-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

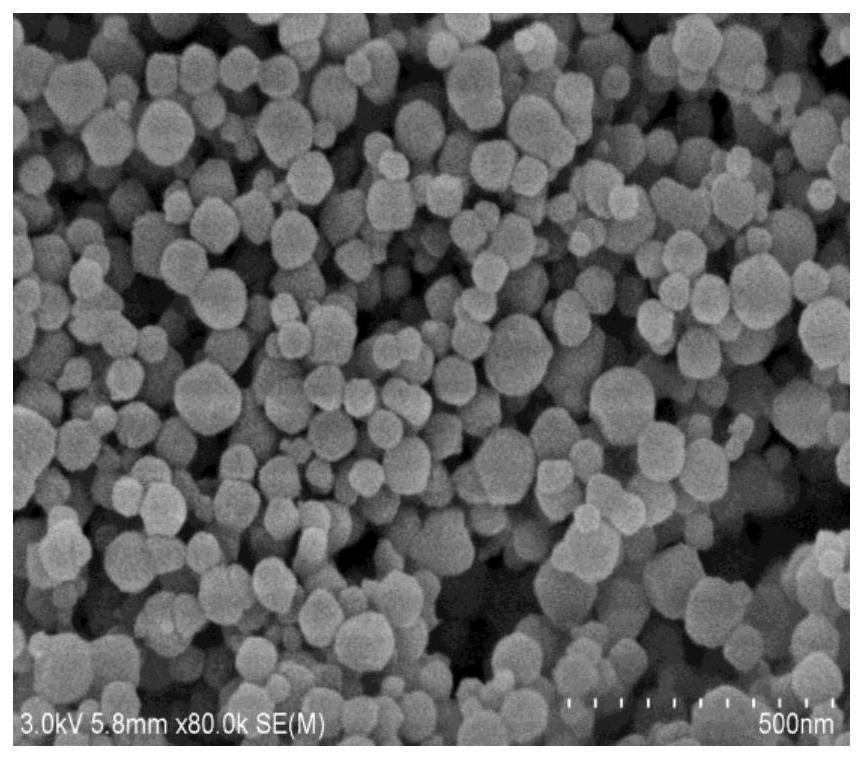

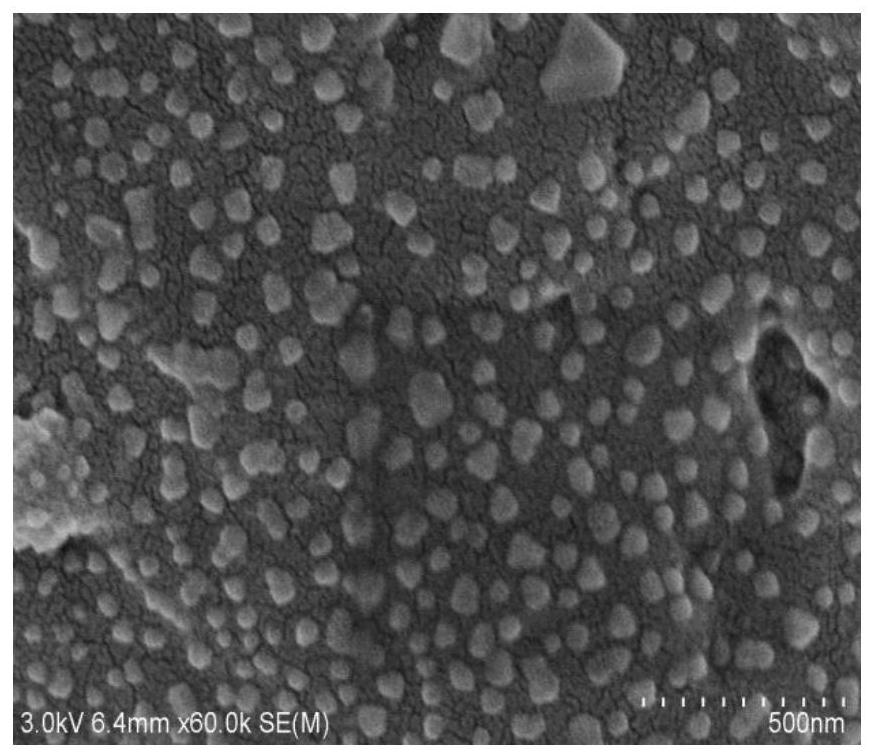

[0038] Preparation of functionalized UIO-66: 4.53g (25mmol) of 2-aminoterephthalic acid and 11.15g (26mmol) of zirconium nitrate metal salt were dissolved in 125ml of acetic acid aqueous solution with an acetic acid concentration of 0.15wt%, and an equal volume of Mix the two solutions evenly and transfer them to a container, and reflux at 100°C for 12-48 hours to obtain a powder product, which is washed and purified with anhydrous methanol and / or anhydrous dichloromethane to obtain the functionalized UIO-66-NH 2 .

[0039] The preparation method of functionalized UIO-66 / polyurethane composite grouting reinforcement material comprises the following steps

[0040] (1) Mix 90 parts of PAPI, 7 parts of DOP, and 8 parts of butyl ether acetate, stir at room temperature for 15 minutes, and store in airtight;

[0041] (2), 10 parts of activated and ground UIO-66-NH 2 Slowly add to the vigorously stirred mixture above, and continue stirring in a closed environment at 55°C for 2 hour...

Embodiment 2

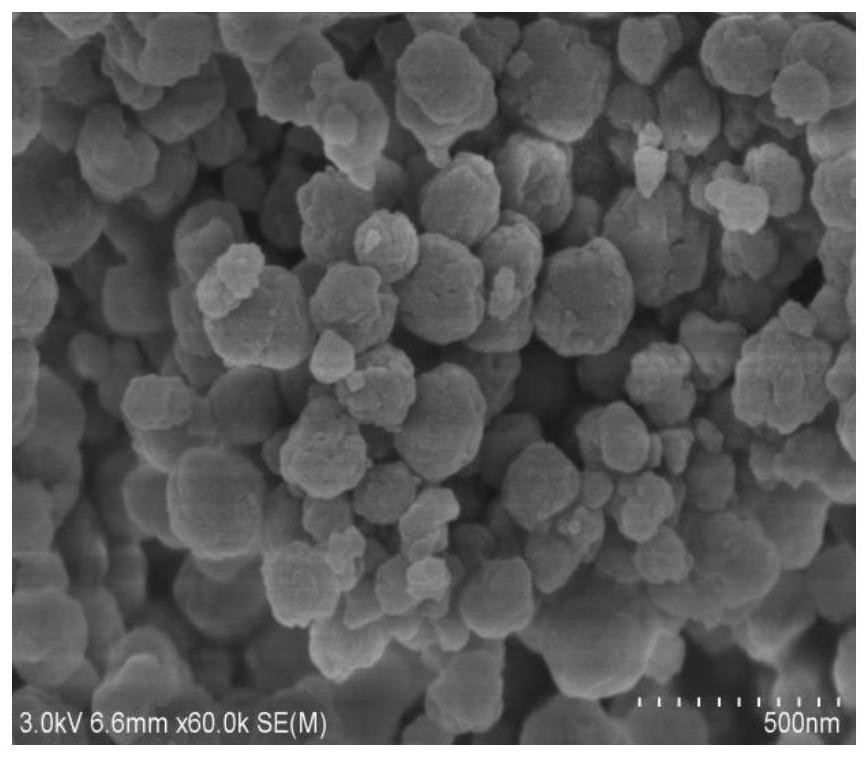

[0045] Preparation of functionalized UIO-66: 4.15g (23mmol) 2,5-dihydroxyterephthalic acid, 11.15g (26mmol) zirconium nitrate metal salt were dissolved in 125ml acetic acid aqueous solution of 1.0wt% acetic acid concentration, and then Equal volumes of the two solutions were mixed and transferred to a container, and refluxed at 100°C for 12-48 hours to obtain a powder product, which was washed and purified with anhydrous methanol and / or anhydrous dichloromethane to obtain the functionalized UIO-66-( Oh) 2 .

[0046] The preparation method of functionalized UIO-66 / polyurethane composite grouting reinforcement material comprises the following steps

[0047] (1) Mix 90 parts of PAPI, 7 parts of DOP, and 8 parts of butyl ether acetate, stir at room temperature for 15 minutes, and store in airtight;

[0048] (2), 10 parts of activated and ground UIO-66-(OH) 2 Slowly add to the vigorously stirred mixture above, and continue stirring in a closed environment at 55°C for 2 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com