ZnO-CuOx/SiO2 catalyst, composite catalyst, and application and preparation method of ZnO-CuOx/SiO2 catalyst and composite catalyst

A composite catalyst and catalyst technology, applied in the chemical industry, can solve problems such as different effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: ZnO-CuO x / SiO 2 Catalyst Synthesis.

[0021] ZnO-CuO x / SiO 2 The synthesis process of the catalyst is as follows: Weigh copper nitrate, zinc nitrate and urea, dissolve them in 30 parts of distilled water, then add 1.9 parts of silica carrier to the system, stir for 2.5 hours and put them into the reaction lined with polytetrafluoroethylene Into the kettle, add 20 parts of distilled water, the reaction kettle is raised to 150°C at a rate of 3°C / min, and the temperature is kept constant for 10h. Then it was evaporated to dryness in a water bath at 90°C, dried at 80°C for 10 hours, and finally placed in a muffle furnace and heated to 400°C at a heating rate of 2°C / min, and kept at a constant temperature for 6 hours. ZnO and CuO in the catalyst x The total mass fraction of ZnO is 5%, and the mass fraction of ZnO in the double metal oxide is adjusted by changing the mass of copper nitrate and zinc nitrate. The mass fraction of each reactant is shown in Tabl...

Embodiment 2

[0027] Example 2: ZnO-CuO x / SiO 2 -Na 2 CO 3 Catalyst Synthesis

[0028] Weigh a certain amount of Na according to the molar ratio of Na element to Cu element in the target catalyst 2 CO 3 Dissolved in 10 parts of twice distilled water, the above prepared ZnO-CuO x / SiO 2 1 part of sample is dispersed to Na 2 CO 3 in aqueous solution. The system was stirred at room temperature for 3 hours, and then heated in a water bath at 90°C to evaporate the water to dryness. The drying temperature was 80°C, and the drying time was 10 hours. The sample was marked as ZnO-CuO x / SiO 2 -Na 2 CO 3 . By changing Na 2 CO 3 To adjust the molar ratio of Na element to Cu element in the catalyst sample. The composition content of each catalyst is shown in Table 2.

[0029] Table 2: Different Na 2 CO 3 content of ZnO-CuO x / SiO 2 -Na 2 CO 3 Catalyst content

[0030]

Embodiment 3

[0031] Example 3: Characterization of the catalyst

[0032] The ESCALAB 250Xi tester from Thermo Fisher Scientific Corporation of the United States was used to test the energy spectrum of the material to analyze the composition and valence of its elements. The binding energy of the elements was corrected according to the binding energy of C1s 284.8eV, and the power was 150W.

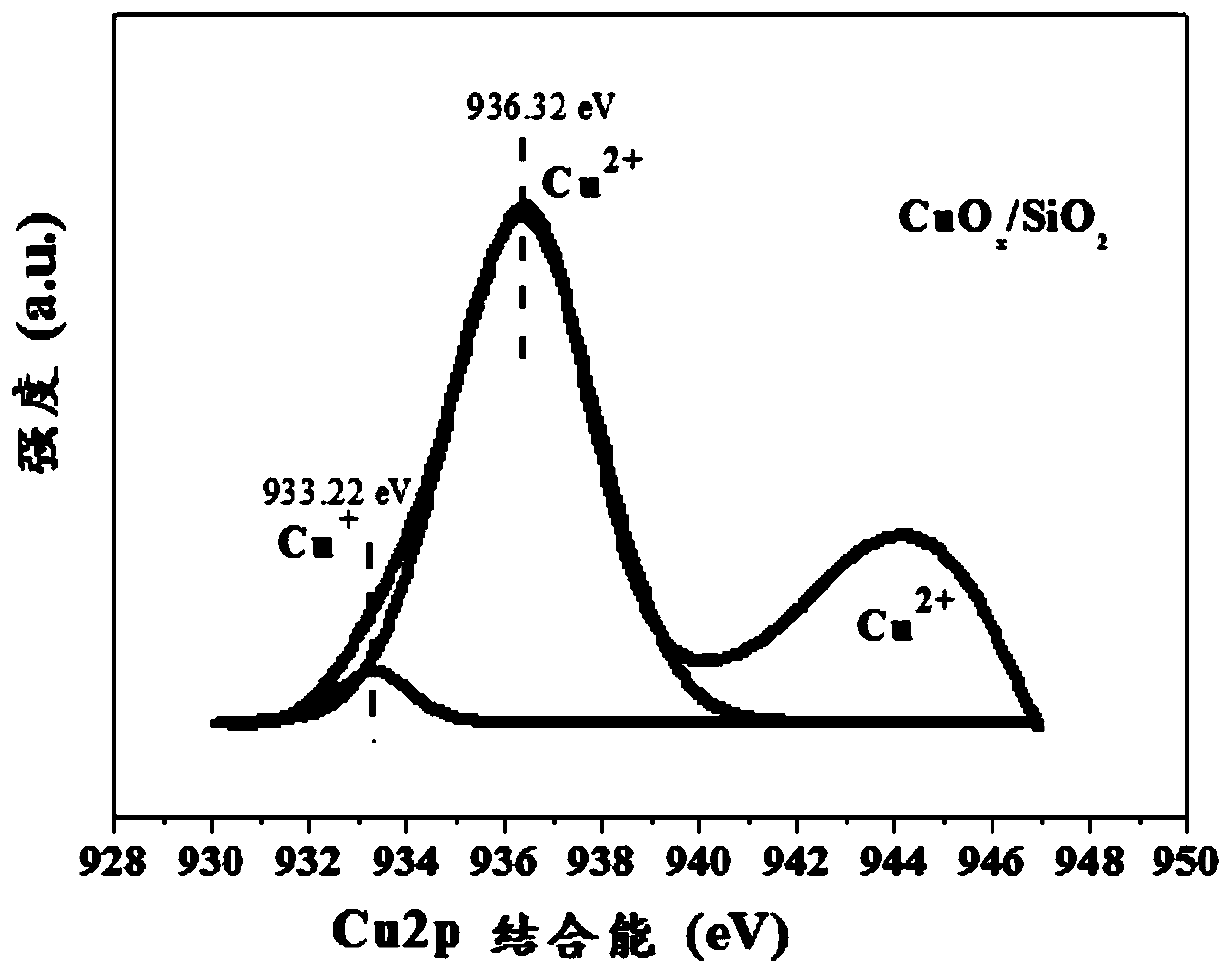

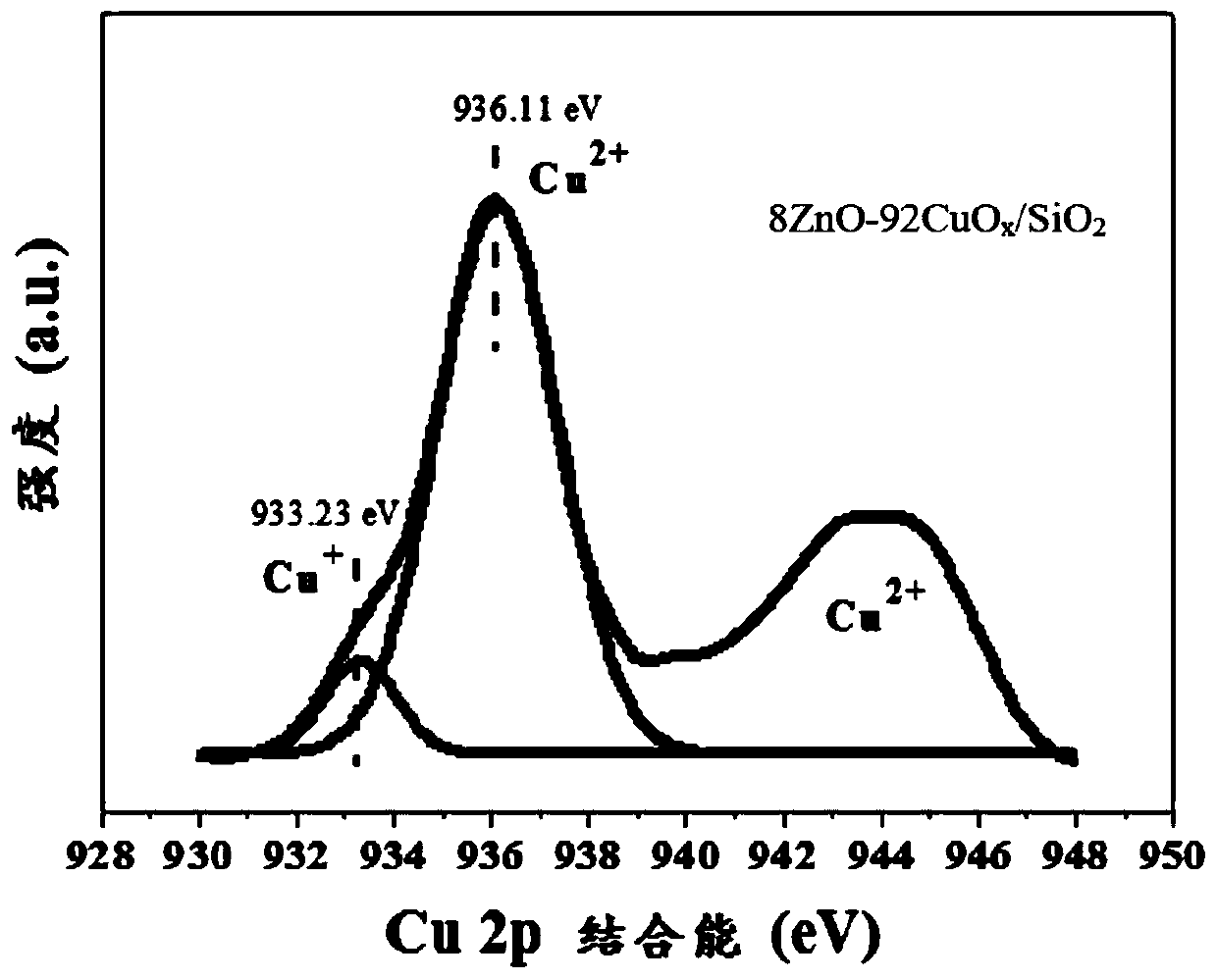

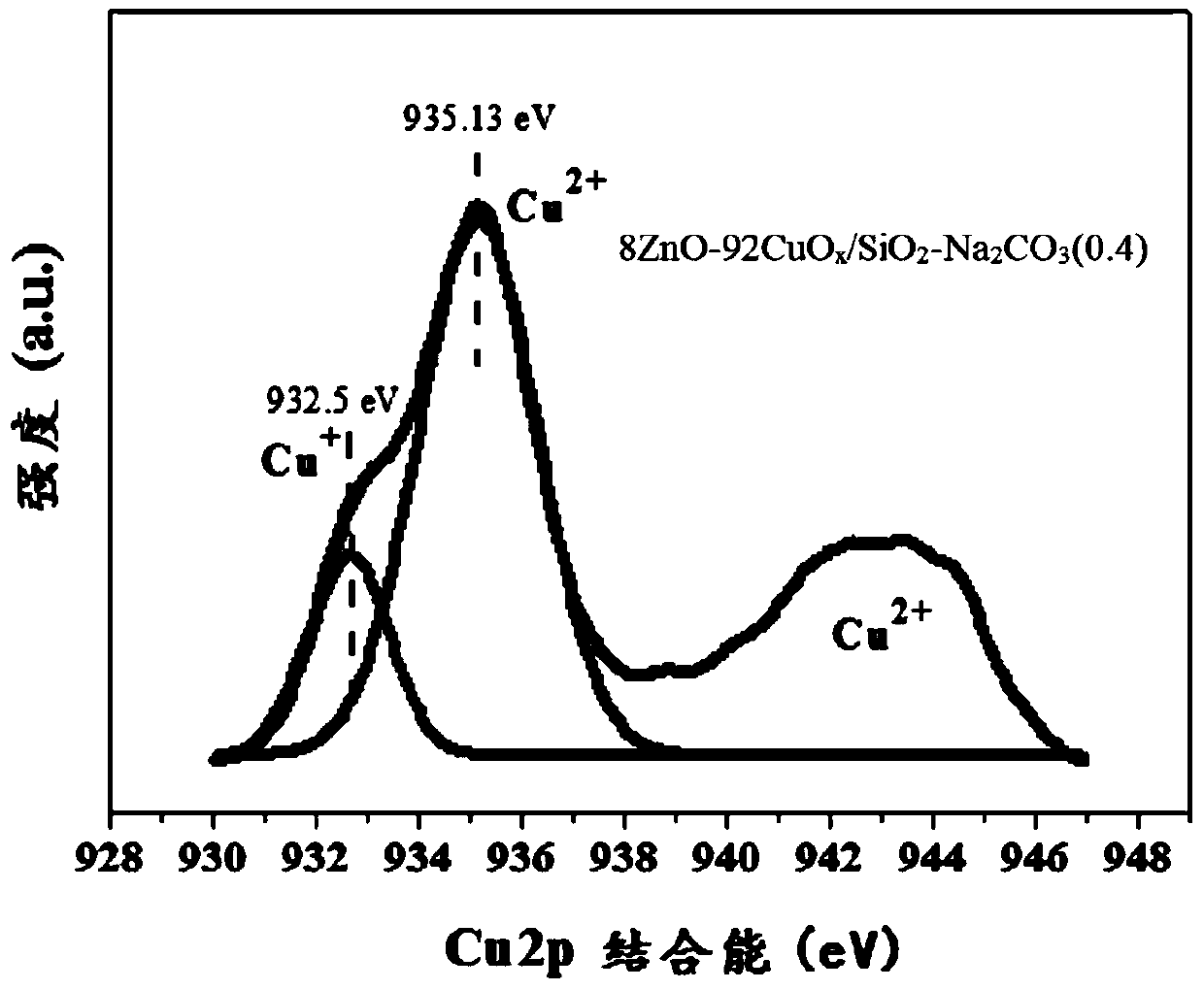

[0033] figure 1 is CuO in Example 1 x / SiO 2 Cu 2p XPS pattern of the catalyst. N 2 CuO treated at 300°C under atmosphere x / SiO 2 The catalyst has a stronger peak at the position of Cu 2p 3 / 2. After peak fitting according to the Peak Fit software, the main peak at 936eV is assigned to Cu 2+ species, the shoulder at 933eV is assigned to Cu + Species characteristic peaks. The XPS spectrum shows that CuO x / SiO 2 The catalyst contains Cu + and Cu 2+ Species, according to the calculation of the peak area of the XPS spectrum, it can be known that Cu + and Cu 2+ The content of species is 4.7%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com