Method for preparing coating by 3D printing overlapping electron beam

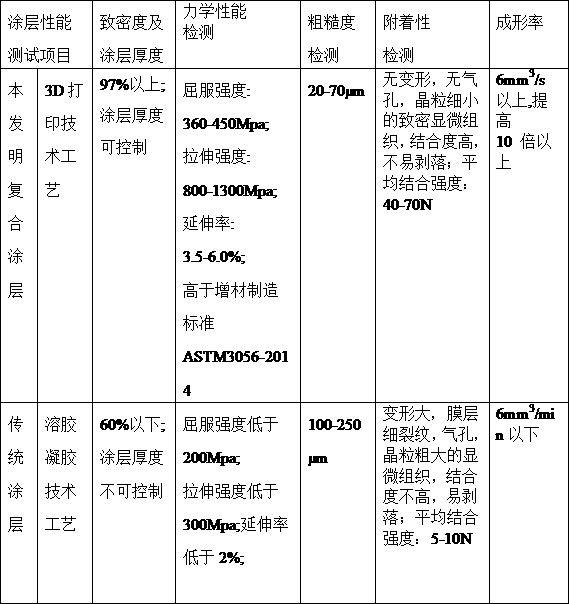

A 3D printing and electron beam technology, applied in coating, metal material coating process, additive manufacturing, etc., can solve the problems of low powder utilization rate, low forming precision, low forming precision, etc., and achieve low cost and smooth surface The effect of flatness and good forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

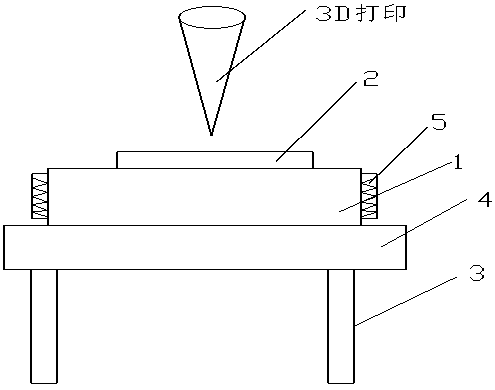

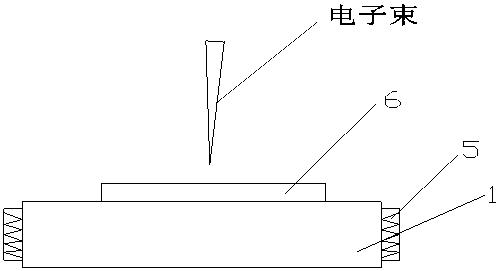

[0017] The method of the present invention is used for 3D printing overlapping electron beams to prepare a coating. Metal or ceramic powder, metal / ceramic powder is mixed into a paste or paste and printed on the surface of the substrate 1 layer by layer through 3D printing. The three-dimensional model is carried out according to the set layer thickness, and then the metal or ceramic powder on the surface of the substrate, and the metal / ceramic powder is mixed into a paste or paste to preheat to form a fused layer 2. The heating device used for this preheating Comprising a high-frequency vibrator 4 and an induction heating coil 5 placed on a workbench 3, the high-frequency vibrator 4 acts on the bottom of the deposited layer 2 and the substrate 1, and the substrate is surrounded by an induction heating coil 5 as preheating, and after preheating, electron beams are used to melt the fused layer to form a metal / ceramic composite gradient coating 6, and finally the metal / ceramic com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com