Door seal ring, door assembly and clothes processing equipment

A sealing ring and door assembly technology, which is applied to other washing machines, washing machines with containers, textiles and papermaking, etc., can solve the problems of easy storage of dirt and dirt, poor sanitation, etc. The effect of preventing leakage and preventing water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

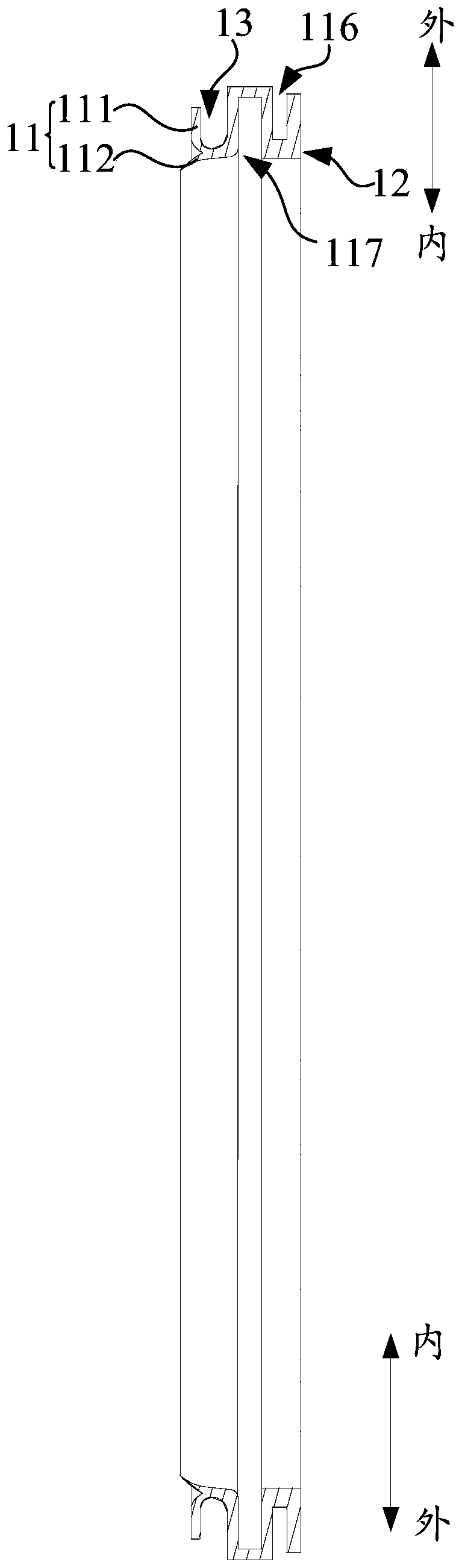

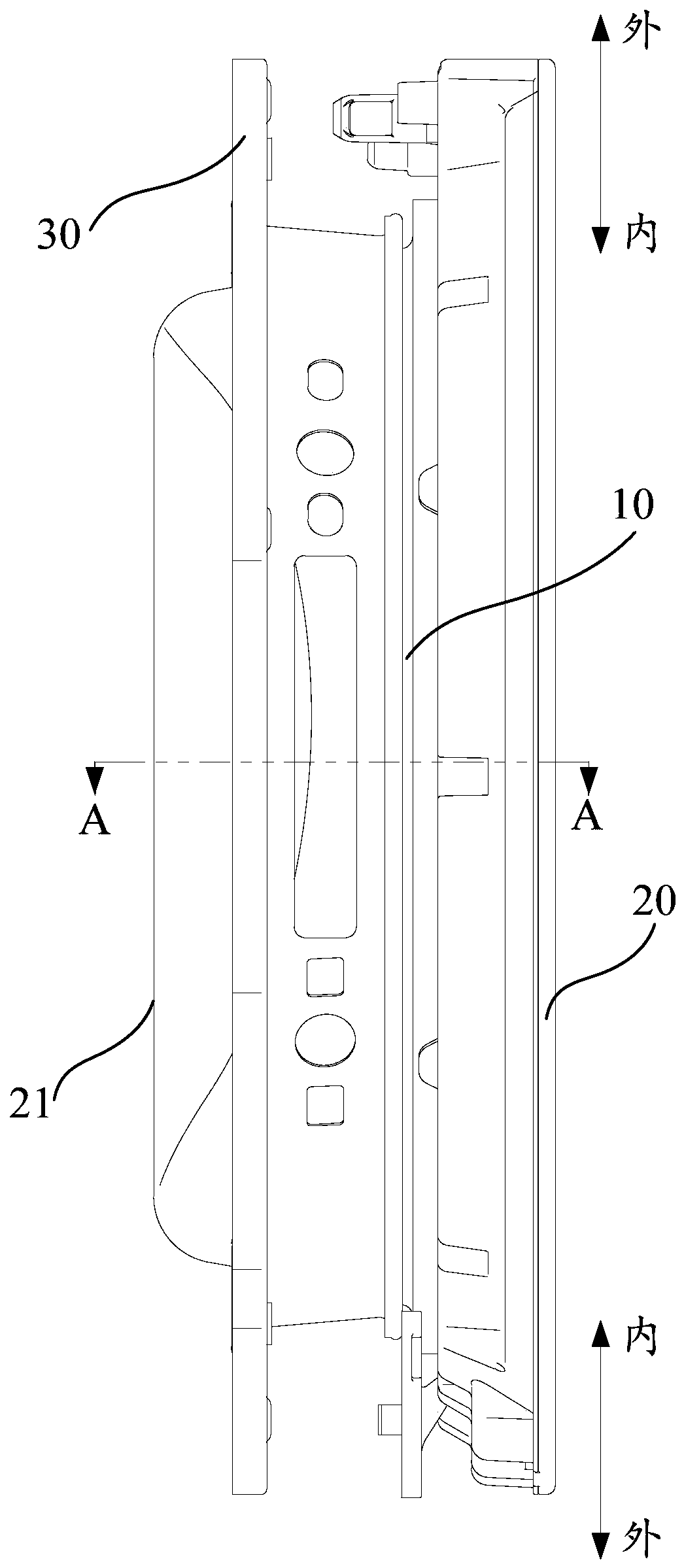

[0051] In addition to the features of the above-mentioned embodiments, it is further defined that: the first lip 121 is connected to the second lip 122 and jointly constructs a bifurcated structure with an opening at one end, the bifurcated structure has two branches, the first lip 121 Part or all of the second lip 122 forms one branch of the bifurcated structure, and part or all of the second lip 122 forms another branch of the bifurcated structure. The first lip 121 is set to be connected with the second lip 122 and jointly construct a bifurcated structure with an opening at one end, so that the opening and closing of the bifurcated structure can be used to further increase the amount of rebound against the sealing part 12, so that when the second When one of the first lip 121 and the second lip 122 abuts against the barrel 30, the one of the first lip 121 and the second lip 122 which abuts against the barrel 30 is deformed and pulled The other rests on the barrel part 30, t...

Embodiment 2

[0054] In addition to the features of any of the above embodiments, it is further defined that the two branches of the bifurcated structure are connected at one end and the other end is a free end, one branch is combined with the connecting end of the other branch, and the free ends are separated from each other , and the distance between one branch and the other branch gradually increases from the connecting end to the free end, so that the opening is formed as a gradually increasing bell mouth. Set the distance between one branch and the other branch to gradually increase from the connecting end to the free end, so that the opening is formed as a gradually increasing bell mouth. The spring ability is stronger, and the structural rebound effect of the abutting sealing part 12 is further improved, thereby further strengthening and improving the abutting sealing effect on the first lip 121 and the second lip 122, improving the sealing reliability, and further improving Opening ...

Embodiment 3

[0057] In addition to the features of any of the above-mentioned embodiments, it is further defined that one of the two branches is located on the outside of the other and protrudes outward obliquely, for example, as Figure 4 As shown, the first lip 121 is located on the outer side of the second lip 122 and is obliquely protruded outward. It can also be understood that the first lip 121 is located on the outer side of the second lip 122 and faces away from the second lip 122. The oblique extension, in this way, is beneficial to increase the contact area between the first lip 121 and the barrel 30 , further strengthening and improving the abutting and sealing effect of the first lip 121 .

[0058] One of the two branches is located on the inner side of the other and protrudes obliquely inwardly. For example, if Figure 4 As shown, the second lip 122 is located on the inner side of the first lip 121 and extends obliquely inward. It can also be understood that the second lip 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com