Shape-selective catalyst for efficiently preparing p-xylene from synthesis gas and light aromatic hydrocarbon

A technology for light aromatics and p-xylene, which is applied in the direction of carbon compound catalysts, catalysts, molecular sieve catalysts, etc., can solve the problems of low conversion efficiency and low xylene yield, and achieve the goal of reducing the rate of coking and carbon deposition and high conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

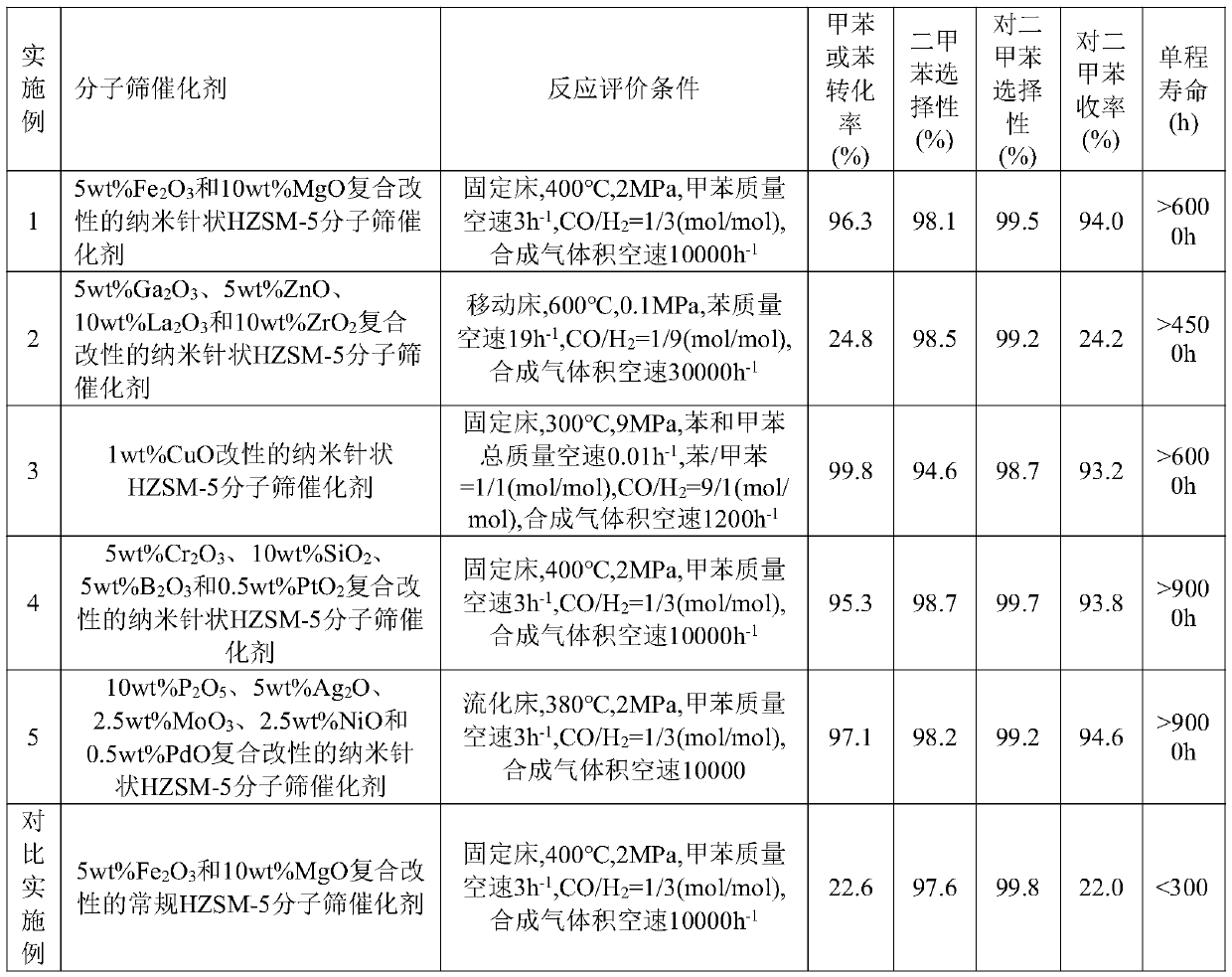

Examples

Embodiment 1

[0020] 1) Weigh 12g of needle-shaped crystals with a cross section of 90nm and a nano-acicular HZSM-5 molecular sieve with a silicon-aluminum atomic molar ratio of 55 and mix them with 8g of alumina binder. After stirring evenly, add an appropriate amount of dilute nitric acid to knead and extrude Shaped, dried at room temperature, and then calcined at 500° C. for 1 hour to obtain a strip-shaped catalyst with a cross-sectional diameter of 1.5 mm. Then the above-mentioned shaped unmodified catalyst particles were sequentially immersed in a certain concentration of ferric nitrate aqueous solution and magnesium nitrate aqueous solution for 12 hours, and the loading capacity of iron oxide and magnesium oxide was determined by the liquid absorption and solution concentration of the unmodified catalyst. They are 1g and 2g respectively, and the impregnated samples are dried at 120°C for 6 hours and then calcined at 500°C for 1 hour. Finally, a nanoacicular HZSM-5 molecular sieve cata...

Embodiment 2

[0023] 1) Weigh 19g of nano-acicular HZSM-5 molecular sieve with a silicon-aluminum atomic molar ratio of 500 and acicular cut-off surface diameter of 3nm, and 1g of silicon oxide binder, roll into a ball, and dry at room temperature, 500 °C for 1 hour to obtain spherical catalyst particles with a diameter of 1.5 mm. Then the above-mentioned unmodified catalyst formed by molding is successively immersed in a certain concentration of gallium nitrate, zinc nitrate, lanthanum nitrate and zirconium nitrate aqueous solution for 12 hours, and the gallium oxide, zinc nitrate and zirconium nitrate are determined by the liquid absorption and solution concentration of the unmodified catalyst. The loads of zinc oxide, lanthanum oxide, and zirconium oxide were 1g, 1g, 2g, and 2g, respectively. The impregnated samples were dried at 120°C for 6 hours, and then calcined at 500°C for 1 hour. Finally, a nano needle-like HZSM-5 catalyst compositely modified with 5wt% gallium oxide, 5wt% zinc ox...

Embodiment 3

[0026]1) Weigh 14g of nano needle-shaped HZSM-5 molecular sieve with a silicon-aluminum atomic molar ratio of 2 and acicular crystal cut-off surface diameter of 400nm, and mix it with 6g of silicon oxide binder, and dry it at room temperature, Calcination was performed for 1 hour to obtain ring-shaped catalyst particles with an outer diameter of 1.5 mm. Then the unmodified catalyst particle of above-mentioned gained molding is excessively impregnated 12 hours in the copper nitrate aqueous solution of certain concentration, determines the loading capacity of copper oxide by the liquid absorption amount and solution concentration of unmodified catalyst to be 0.2g, the sample after impregnating is in After drying at 120°C for 6 hours, it was baked at 500°C for 1 hour. Finally, a 1wt% copper oxide-modified nanoacicular HZSM-5 catalyst was obtained.

[0027] 2) 5g of the above-mentioned copper oxide modified molecular sieve catalyst is loaded into a miniature adiabatic fixed-bed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com