High-strength and high-toughness thick-plate structural steel for low temperature and heat treatment method thereof

A heat treatment method, high-strength and high-toughness technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of lack of heat treatment temperature, time and steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

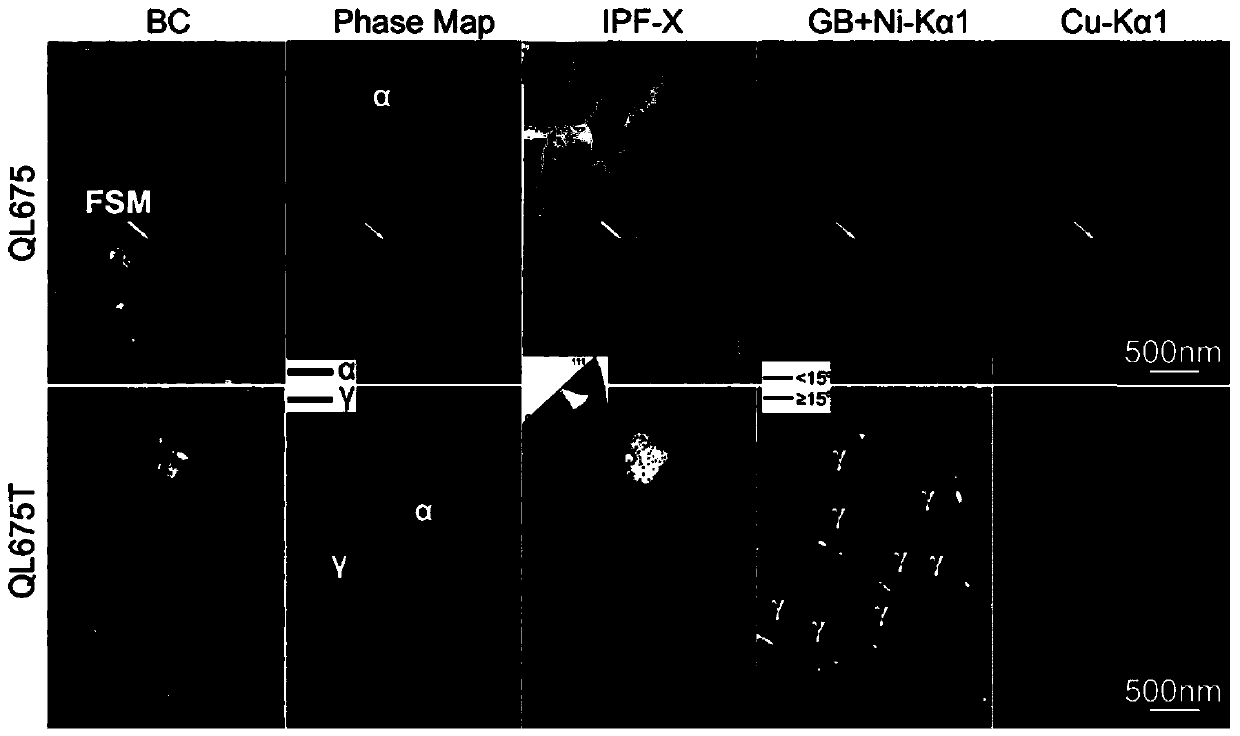

[0040] A kind of high-strength and high-toughness thick plate structural steel for low temperature, the composition is by weight percentage:

[0041] C: 0.03-0.08%, Cr: 0.8-1.9%, Mn: 0.01-1.0%, Ni: 3.5-7%, Mo: 0.2-0.5%, V: 0.15-0.2%, Nb: 0.01-0.05%, Cu : 1.2-3.8%, Al: 0-0.5%; P: <0.015%, S: <0.010%, the balance is Fe and unavoidable impurities.

[0042] The heat treatment method for the above-mentioned high-strength and high-toughness thick plate structural steel for low temperature comprises the following steps:

[0043] (1) Smelting into steel ingots or billets according to the ratio, soaking at 1150-1250°C, after a total of not less than 12 passes of rough rolling and finish rolling, the final rolling temperature is not less than 750°C, and the cumulative compression ratio is 4-7. Air cooling or water cooling after production;

[0044] (2) Off-line heat treatment:

[0045] (2-a) Quenching, denoted as Q: Austenitizing at 870-915°C for 40-120min, water cooling;

[0046] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com