A core-shell structure type wave-absorbing material and its preparation method and application

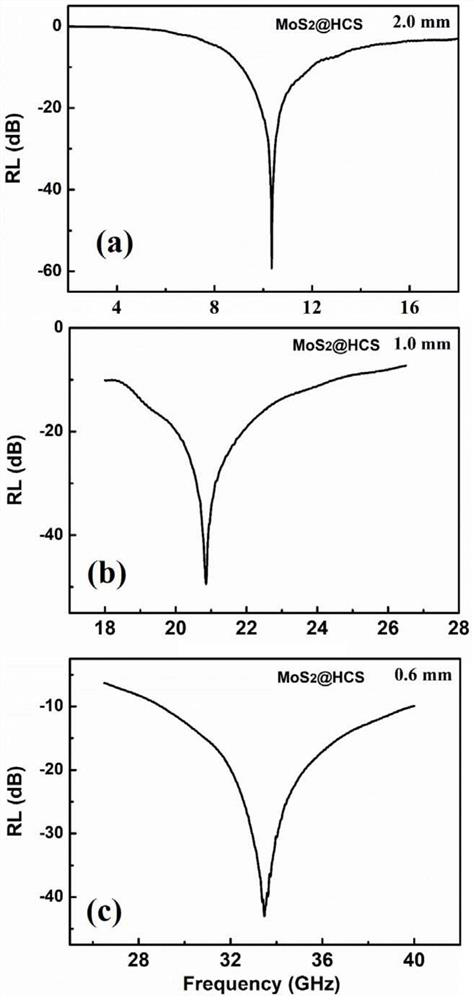

A technology of wave-absorbing materials and core-shell structure, applied in the field of wave-absorbing materials, can solve the problems of impedance mismatch that plagues scientific research workers, has not been solved well, and uneven distribution of wave-absorbing agents, etc., and achieves excellent impedance matching characteristics , Guarantee normal performance and reduce the effect of skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

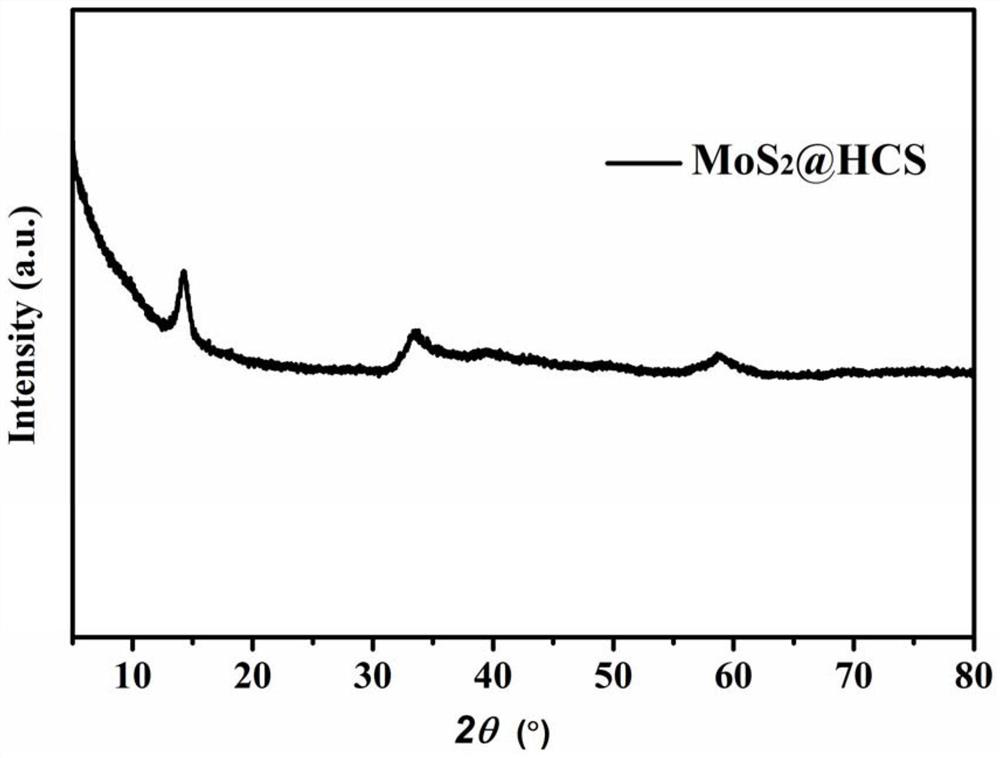

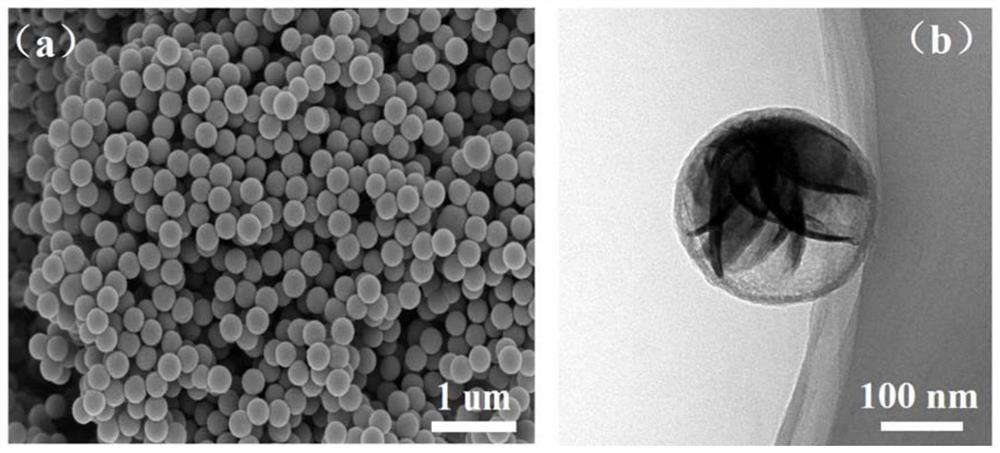

[0044] (1) Adoption of the Stober Method (Reference: Werner Stober Et.Al.Controlled Growth Ofmonodispers, Journal of Colloid Andinterface Science, 1968, 26, 62-69) Prepare high dispersible hollow carbon balls . It is weighing 100 mg prepared hollow carbon ball (250 nm having a particle diameter) in a 50 ml beaker, and thoroughly stirred with 5 ml of 5 ml of methanol, thoroughly stirring for 1 h to obtain a mixed solution; 2.0 g of sodium molybdate dihydrate (NA) 2 MOO 4 .2h 2 O) and 4.0 g of thiramide (CH 3 CSCH 2 The above mixed solution is sequentially added and stirred for 2 h, so that it is sufficiently dissolved, and then the resulting reaction solution is transferred to a solvent thermal reaction in a solvent having a capacity of 50 ml, and the inner sleeve is placed in a stainless steel outer sleeve. The reaction was reacted at 200 ° C for 24 h.

[0045] (2) After the reaction, the product was placed in a centrifuge tube to centrifuge at a high speed of 20 min, and the bott...

Embodiment 2

[0050] The preparation step is basically the same as that of Example 1, and the difference is only to: replace the sodium bore borid sodium boreate in step (1) as sodium tungstate, and produce nuclear shell structural WS. 2 @HCS composite microwave absorbent.

Embodiment 3

[0052] The preparation step is basically the same as that of Example 1, and the difference is only that the sodium molybdate dihydrate in step (1) is replaced by sodium vanadate, and the thiramide is replaced by sodium anthramide. Structural VTE 2 @HCS composite microwave absorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com