Graphene oxide hybrid multi-wall self-lubricating micro-nano capsule and preparation method thereof

A graphene and self-lubricating technology, which is applied in the field of graphene oxide hybrid multi-wall self-lubricating micro-nanocapsules and its preparation, can solve the problems of ineffective control of the content of inorganic components, weak interface bonding, and small specific gravity, and achieve Effects of overcoming poor anti-wear performance, high thermo-oxidative stability, high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

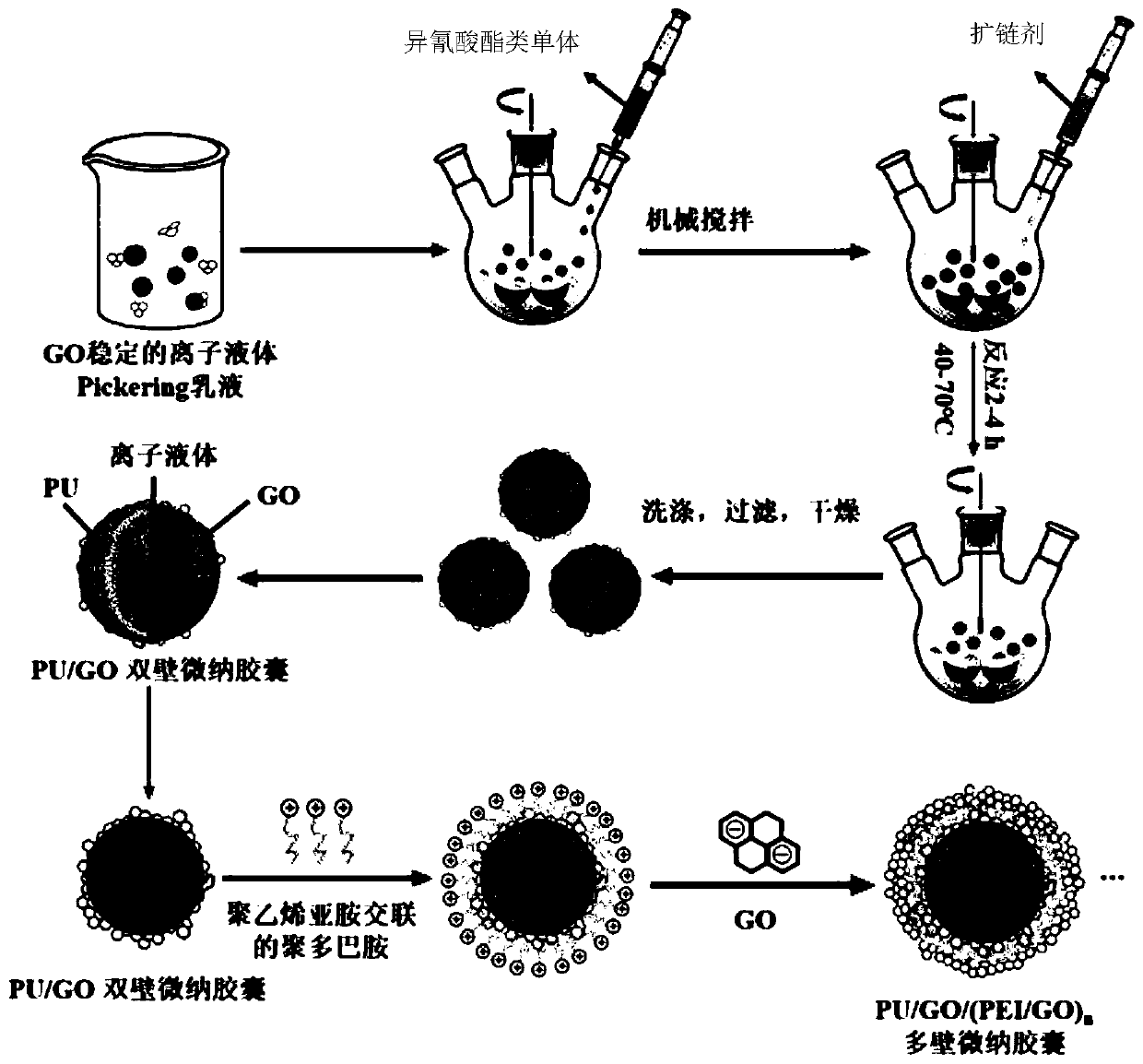

[0060] In the first aspect, the present invention provides a method for preparing graphene oxide hybrid multi-wall self-lubricating micro-nanocapsules. This preparation method comprises the steps:

[0061] The present invention provides a graphene oxide hybrid multi-wall self-lubricating micro-nanocapsule in a first aspect, the micro-nanocapsule uses an ionic liquid as a core material and a multilayer graphene oxide hybrid system as a wall material; The structure of the multilayer graphene oxide hybrid system from the inside to the outside is: polyurea / graphene oxide / (polyethyleneimine / graphene oxide) n , n represents the number of layers of polyethyleneimine / graphene oxide, n≥1 and is a natural number. The value of n may be 1. At this time, the structure of the multi-layer graphene oxide hybrid system is: polyurea / graphene oxide / polyethyleneimine / graphene oxide from inside to outside. The value of n can also be more than or equal to 2. At this time, the structure of the mul...

Embodiment 1

[0109] (1) Add an ionic liquid to the graphene oxide aqueous solution to adjust the pH of the system to 3, the concentration of the graphene oxide aqueous solution to be 0.05 wt%, and the mass ratio of the ionic liquid to water to be 1:10. The above mixed solution was ultrasonically dispersed for 5 min, and the ultrasound was carried out in an ice bath to prepare GO-stabilized Pickering emulsion A.

[0110] (2) Add isophorone isocyanate to solution A, the mass ratio of isocyanate and ionic liquid is 1:1, after mechanical stirring for 5 minutes (rotating speed 300r / min), add the aqueous solution of 10wt% triethylenetetramine, isocyanate and triethylenetetramine The mass ratio of ethylene tetramine was 1:1. The system was heated to 40°C and reacted for 4 hours to prepare polyurea / graphene oxide (PU / GO) double-walled micro-nanocapsules coated with ionic liquid.

[0111] (3) configure tris(hydroxymethyl)aminomethane (Tris) aqueous solution, the concentration is 0.1wt%, adjust the ...

Embodiment 2

[0115] (1) Add an ionic liquid to the graphene oxide aqueous solution, adjust the pH of the system to be 3, the concentration of the graphene oxide aqueous solution is 0.01wt%, and the mass ratio of the ionic liquid to water is 1:20. The above mixed solution was ultrasonically dispersed for 10 min, and the ultrasound was carried out in an ice bath to prepare GO-stabilized Pickering emulsion A.

[0116] (2) Toluene diisocyanate is added to solution A, the mass ratio of toluene diisocyanate and ionic liquid is 1:2, after mechanical stirring for 5 minutes (speed 400r / min), add 15wt% triethylenetetramine aqueous solution, toluene diisocyanate The mass ratio of triethylenetetramine to triethylenetetramine was 1:1, the system was heated up to 50 °C, and reacted for 3 hours to prepare polyurea / graphene oxide (PU / GO) double-walled micro-nanocapsules coated with ionic liquid.

[0117] (3) configure tris(hydroxymethyl)aminomethane (Tris) aqueous solution, the concentration is 0.3wt%, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com