Antibacterial non-woven fabric and manufacturing process thereof

A technology of non-woven fabrics and spunlace non-woven fabrics, which is applied in the direction of melt spinning, non-woven fabrics, and rayon manufacturing, and can solve the problem of poor mechanical properties such as breaking strength of antibacterial non-woven fabrics, loss of antibacterial effect, and application range Restricted problems, to achieve excellent antibacterial performance, good antibacterial effect, high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

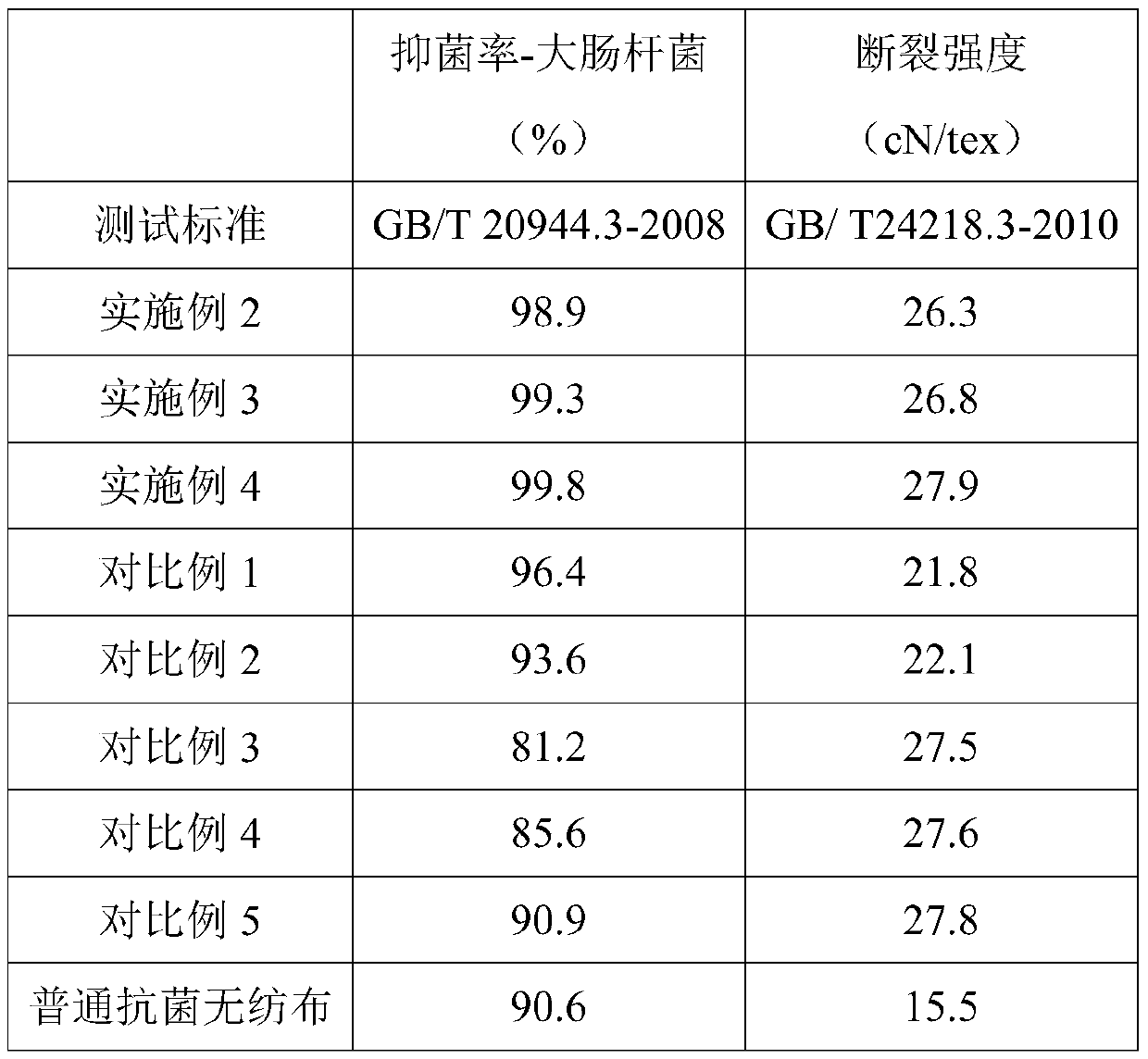

Examples

Embodiment 1

[0051] A kind of antibacterial nonwoven fabric, described antibacterial nonwoven fabric is made by composite fiber through spunlace nonwoven fabric production process;

[0052] The composite fiber has a skin-core structure, including a core layer and a skin layer; the cross-sectional profile of the core layer is a regular pentagon, the skin layer is wrapped on the outer surface of the core layer, and the cross-sectional profile of the skin layer is a circle shape; the ratio of the cross-sectional area of the core layer and the cortex is 1: (0.28~0.35);

[0053] The core layer is made of the following raw materials in parts by weight: 95-100 parts of polyethylene terephthalate, 2-5 parts of hydroxyl-terminated polysiloxane emulsion, 2-3.5 parts of pentaerythritol adipate, 10-15 parts of filler;

[0054] The skin layer is made of the following raw materials in parts by weight: 55-65 parts of polyethylene terephthalate, 30-35 parts of polyether polyurethane elastomer, 10 parts...

Embodiment 2

[0077] A kind of antibacterial nonwoven fabric, described antibacterial nonwoven fabric is made by composite fiber through spunlace nonwoven fabric production process;

[0078] The composite fiber has a skin-core structure, including a core layer and a skin layer; the cross-sectional profile of the core layer is a regular pentagon, the skin layer is wrapped on the outer surface of the core layer, and the cross-sectional profile of the skin layer is a circle shape; the ratio of the cross-sectional area of the core layer and the skin layer is 1:0.28;

[0079] The core layer is made of the following raw materials in parts by weight: 95 parts of polyethylene terephthalate, 2 parts of hydroxyl-terminated polysiloxane emulsion, 2 parts of pentaerythritol adipate, and 10 parts of filler;

[0080] The skin layer is made of the following raw materials in parts by weight: 55 parts of polyethylene terephthalate, 30 parts of polyether polyurethane elastomer, 10 parts of maleic anhydride...

Embodiment 3

[0099] A kind of antibacterial nonwoven fabric, described antibacterial nonwoven fabric is made by composite fiber through spunlace nonwoven fabric production process;

[0100] The composite fiber has a skin-core structure, including a core layer and a skin layer; the cross-sectional profile of the core layer is a regular pentagon, the skin layer is wrapped on the outer surface of the core layer, and the cross-sectional profile of the skin layer is a circle shape; the ratio of the cross-sectional area of the core layer and the skin layer is 1:0.35;

[0101] The core layer is made of the following raw materials in parts by weight: 100 parts of polyethylene terephthalate, 5 parts of hydroxyl-terminated polysiloxane emulsion, 3.5 parts of pentaerythritol adipate, and 15 parts of filler;

[0102] The skin layer is made of the following raw materials in parts by weight: 65 parts of polyethylene terephthalate, 35 parts of polyether polyurethane elastomer, 13 parts of maleic anhydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com