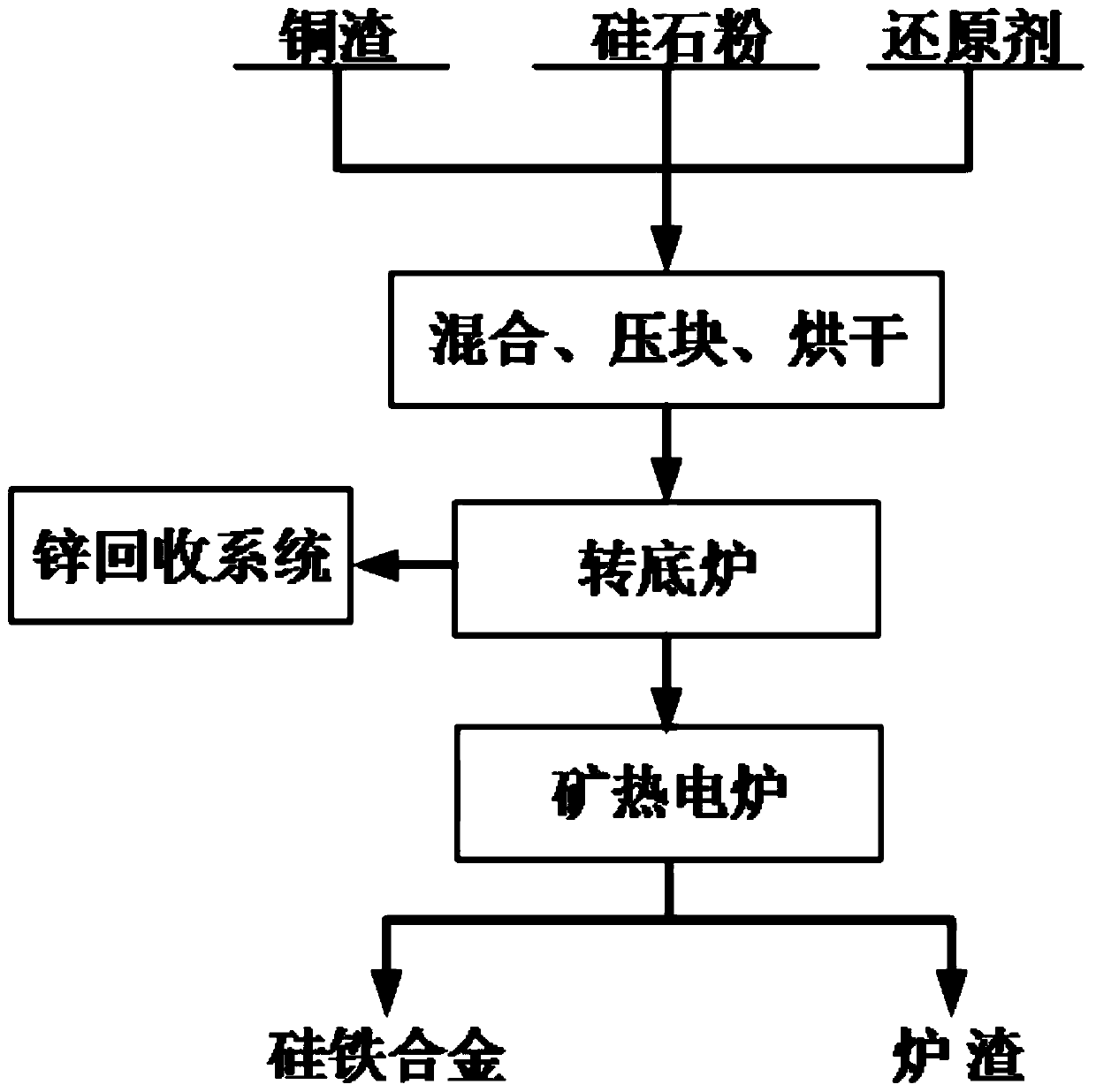

Copper slag treatment method by utilizing rotary hearth furnace direct reduction and ore-smelting electric furnace smelting reduction

A technology of submerged thermal electric furnace and rotary hearth furnace, which is applied in the direction of improving process efficiency, can solve the problems of high energy consumption, no recovery of zinc elements, and no reasonable utilization, etc., to save energy consumption, save coking production, and smelting electricity. consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The composition of tailings after flotation of a certain copper slag is shown in the following table:

[0039] element TF FeO Cu CaO MgO SiO 2

al 2 o 3

Na 2 o

K 2 o

S P Pb Zn content 43.21 44.44 0.17 1.82 2.62 31.34 3.32 0.25 1.02 0.19 0.02 0.26 1.09

[0040] 1) Preparation of copper slag carbon-containing pellets: the copper slag, SiO-containing 2 98% silica powder (particle size composition: 3mm~2mm accounts for 14%, 2mm~1mm accounts for 45%, 1mm or less accounts for 41%), -3mm accounts for 100% coking coal (caking index 95) according to the mass ratio of 100 :270:250 mixed uniformly and pressed into carbon-containing pellets, the carbon-containing pellets were dried in a chain dryer until the moisture content was less than 2%, and the copper slag carbon-containing pellets whose compressive strength was obtained were 750N / piece;

[0041] 2) Rotary hearth furnace reduction and pellet coking enha...

Embodiment 2

[0044] The composition of tailings after flotation of a certain copper slag is shown in the following table:

[0045] element TF FeO Cu CaO MgO SiO 2

al 2 o 3

Pb Zn S P K 2 o

Na 2 o

content 41.55 41.82 0.19 1.85 1.81 33 3.15 0.54 2.23 0.24 0.018 0.36 0.12

[0046] 1) Preparation of copper slag carbon-containing pellets: the copper slag, SiO-containing 2 97.5% silica powder (particle size composition: 3mm~2mm accounts for 15%, 2mm~1mm accounts for 40%, 1mm or less accounts for 45%), -3mm accounts for 100% coking coal (caking index 100) according to the mass ratio of 100 :260:260 mixed uniformly and pressed into carbon-containing pellets, and the carbon-containing pellets were dried in a grate dryer until the moisture content was less than 2%, to obtain copper slag carbon-containing pellets with a compressive strength of 730N / piece;

[0047] 2) Rotary hearth furnace reduction and pellet coking enhancement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com