Preparation method of high-performance ultra-fine structure carbon graphite product

A graphite product and high-performance technology, applied in the field of carbon graphite, can solve problems such as cost increase, raw material shortage, cracking, etc., and achieve the effect of increasing density and strength, reducing anisotropy, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention discloses a method for preparing a high-performance ultra-fine structure carbon graphite product, which includes the following steps: composite graphite powder and a first binder in a granulated manner, and carbonize to obtain a composite granular material; The composite granular material is mixed with the second binder, additives, and graphitization accelerator in liquid phase, then dried, shaped, impregnated and roasted repeatedly for 3-8 times, and graphitized to obtain high-performance ultra-fine structure carbon graphite products.

[0021] As a preferred solution, the particle size of the graphite micropowder used in the present invention is ≤3 microns. This raw material solves a series of problems caused by energy materials such as shortage of raw materials, rising costs, and environmental pollution. At the same time, after composite carbonization, the material forms isotropic aggregates to reduce the anisotropy of subsequent...

Embodiment 1

[0039] 1. Granulation:

[0040] Add 40kg of asphalt with a softening point of 90°C to 400kg of alcohol, stir evenly and add 200kg of graphite powder with a particle size below 3 microns;

[0041] Granulating and drying by means of spray drying;

[0042] After drying, it is carbonized at 500°C, and the granulation is finalized. The particle size is about 30 μm, and the maximum particle size is less than 70 μm.

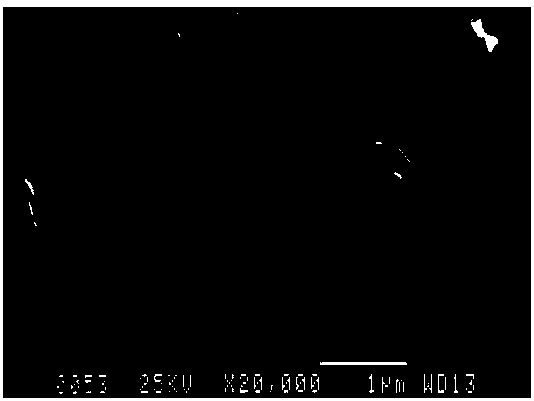

[0043] figure 1 It is the SEM figure of the raw material graphite powder that the present embodiment adopts. It can be seen from the figure that the single particle size of graphite micropowder is less than or equal to 3 μm, and the graphite particles are mostly flakes, so it is difficult to make fine-structured graphite by direct use, and the isotropy is very poor.

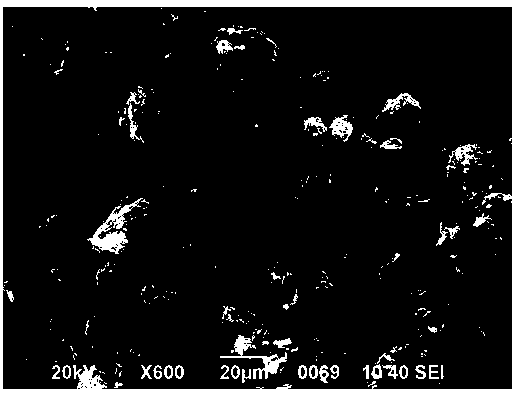

[0044] figure 2 This is the SEM image of graphite after secondary granulation in this example, the secondary particle size after granulation is about 30 μm, and the maximum particle size is less than ...

Embodiment 2

[0068] 1. Granulation:

[0069] Add 40kg of asphalt with a softening point of 90°C to 400kg of alcohol, add 40kg of asphalt, stir well and add 200kg of graphite powder below 2μm;

[0070] It is dried by freeze-drying, and then granulated by kneading and granulation. After granulation, it is carbonized at 800 ° C to shape the granules. The particle size is about 30 μm, and the maximum particle size is less than 70 μm.

[0071] 2. Made of extremely fine structure carbon graphite products:

[0072] Weigh 400kg of alcohol, add 2kg of PVA and stir for 30 minutes, add 40kg of asphalt with a softening point of 280°C, and 10kg of iron oxide for stirring;

[0073] After uniform dispersion, add 200kg of granulated main material and mix evenly;

[0074] to dry the liquid;

[0075] Isostatic pressing using an isostatic press;

[0076] Use low temperature asphalt (softening point less than 70) for impregnation;

[0077] Carry out roasting at 900 degrees Celsius, the roasting time is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com