Vinylidene-fluoride resin film

A technology of vinylidene fluoride and polyvinylidene fluoride, which can be used in synthetic resin layered products, other household appliances, transportation and packaging, etc. The effect of permeability and excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

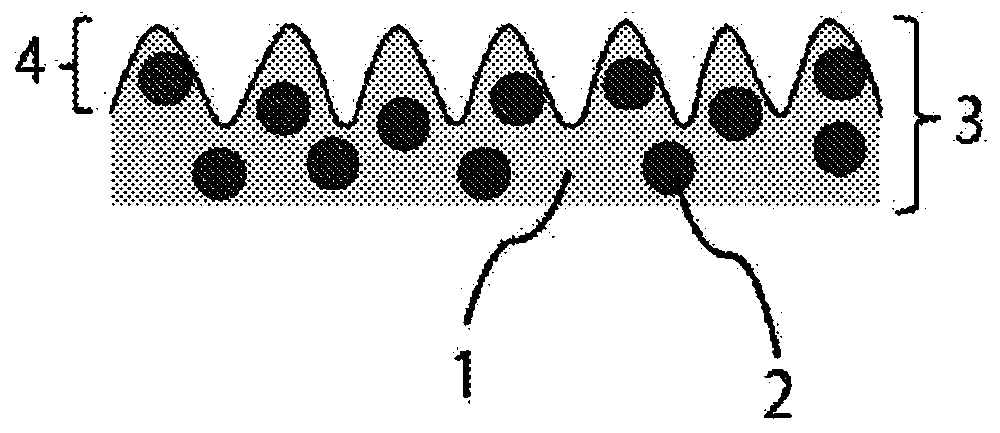

[0203] In Example 1, a single-layer vinylidene fluoride-based resin film was produced. The raw materials and production conditions are shown in Table 1 below.

[0204] 50% by mass of 1000HD, 30% by mass of K720C, and 20% by mass of MGSS were premixed in an unmelted state, and then, while adding 10 parts by mass of GM-0449S-2 to 100 parts by mass of the aforementioned mixture, Mix uniformly at a resin temperature lower than 250°C with the aforementioned melt mixing equipment to obtain granular mixture A. The granular mixture A was melted at a screw speed of 50 RPM at a maximum temperature setting of 240° C. in the extruder A described above, and extruded in a film form from a T-die. In the pulling part (which is a hard chrome-plated roller (the arithmetic mean roughness of the surface Ra = 0.2 μm) circulated with cooling water adjusted to a temperature of 45° C. and a sand-containing embossed rubber roller (#600) are pressed together. produced) while pulling the extruded film...

Embodiment 2~4

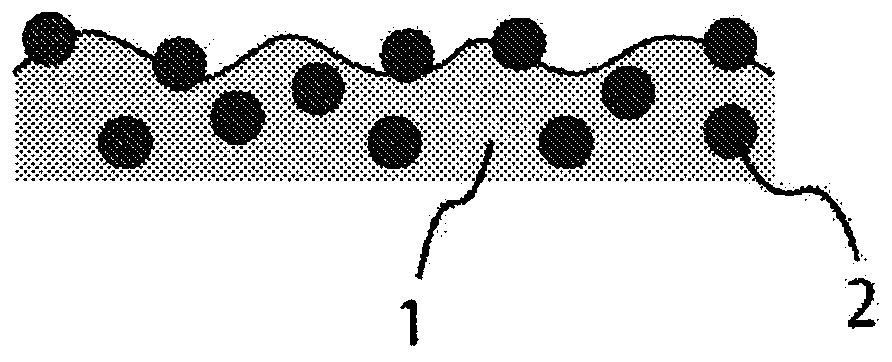

[0207] In Examples 2 to 4, vinylidene fluoride-based resin films having a single-layer structure were produced as well.

[0208] About Examples 2-4, it manufactured by the method similar to Example 1. The raw materials used, production conditions, and performance are shown in Table 1 below.

[0209]

Embodiment 5

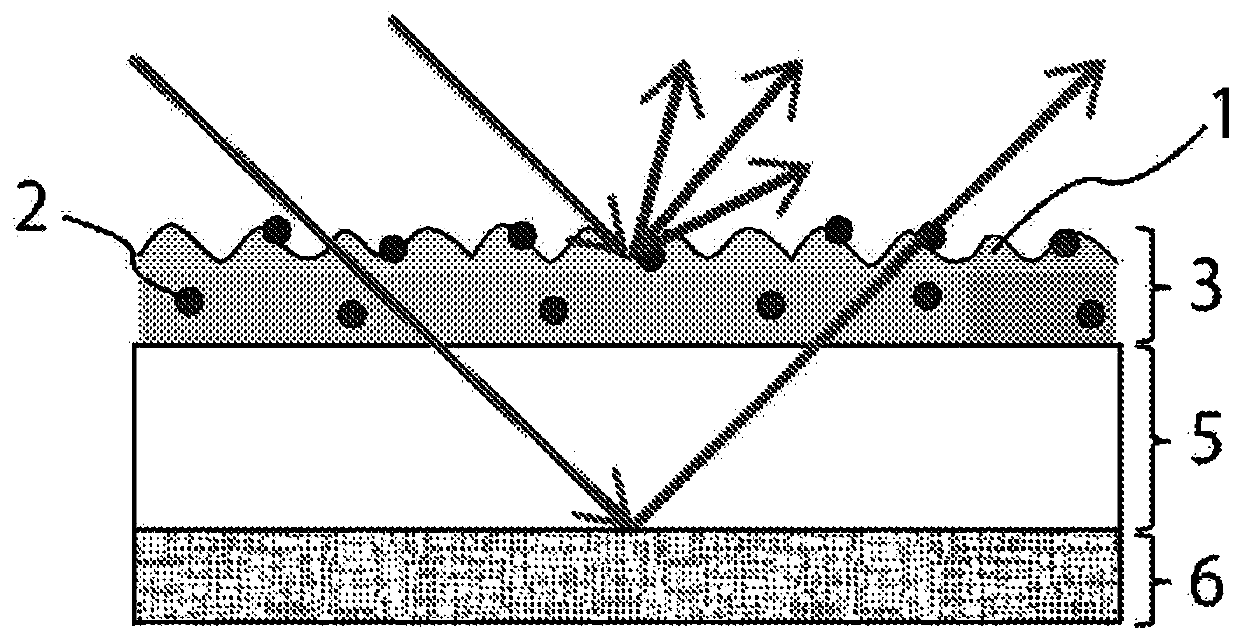

[0211] In Example 5, a laminated film was produced. The raw materials and production conditions of the surface layer and the back layer are shown in Table 2 below. In addition, in Example 5, the ultraviolet absorber was added to the back layer.

[0212] 50% by mass of 1000HD, 30% by mass of K720, and 20% by mass of MGSS were premixed in an unmelted state, and then, while adding GM-0449S-210 parts by mass to 100 parts by mass of the aforementioned mixture, use The aforementioned melt-mixing equipment mixed uniformly at a resin temperature lower than 250° C. to obtain granular mixture A.

[0213] In addition, 20% by mass of K720 and 80% by mass of HBZG60 were pre-mixed in an unmelted state, and then uniformly mixed at a resin temperature lower than 250° C. using the aforementioned melt-mixing equipment to obtain granular mixture B.

[0214] For the granular mixture A, in the aforementioned extruder A, the maximum set temperature in the barrel is 240° C., and it is melted at a sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com