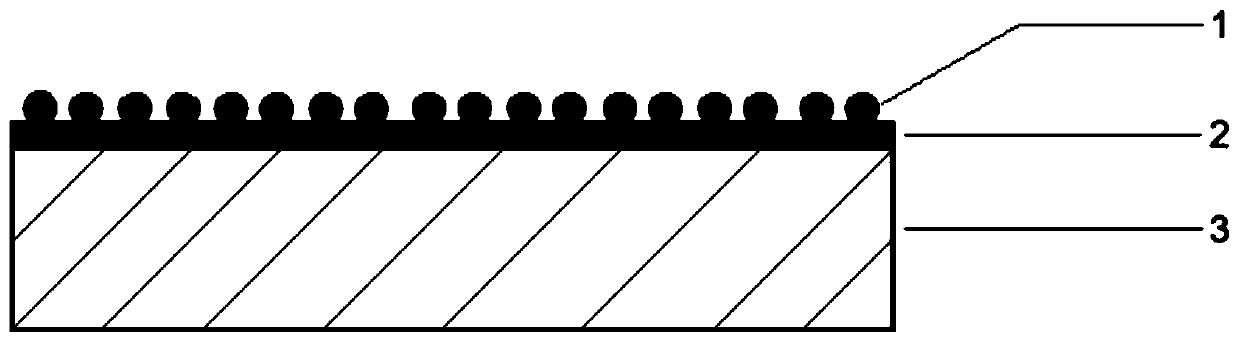

InAs quantum dot-based remote epitaxial structure, preparation method and application

An epitaxial structure and quantum dot technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problem of reducing battery short-circuit current and photoelectric conversion efficiency, low size and position distribution uniformity, and affecting quantum dot crystals. Quality and other issues, to achieve the effect of alleviating large tearing, reducing defect density, and inhibiting structural dissimilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) The highly doped n-type GaAs substrate is used as the base material, the crystal orientation is (100), and the Si doping concentration is 5.1×10 18 / cm 3 , the carrier mobility is 1336cm 2 / (vs.). In order, ultrasonic cleaning was performed with AR grade acetone, ethanol and ultrapure water for 5 minutes, followed by rinsing with 6% hydrochloric acid for 3 minutes, and then rinsing with deionized water.

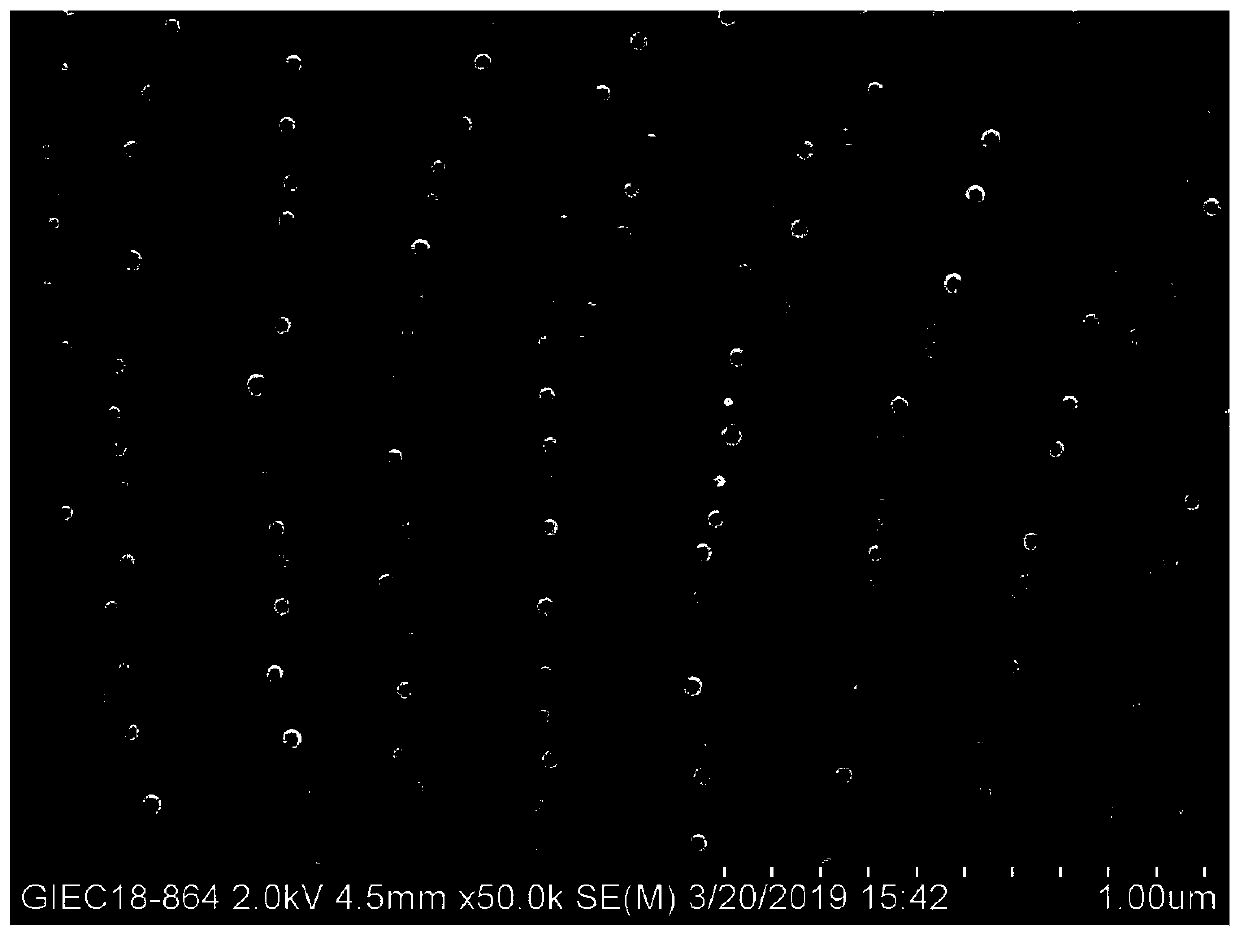

[0032] (2) Graphene transfer: Graphene is a single-layer graphene grown on a copper base, and the preparation method is a conventional CVD method (refer to Dervishi E, Li Z, Watanabe F, et al.Large-scale graphene production by RF-cCVD method[J].Chemical Communications, 2009(27):4061.), before transferring, graphene needs to be transferred to ferric chloride solution of 1mol / L, after the copper metal substrate is completely dissolved, use PMMA accompanying sheet to transfer graphite The alkene was transferred in ultrapure water three times, each time for 3 minute...

Embodiment 2

[0038] (1) Using a highly doped n-type GaAs substrate as the base material, the crystal orientation is (001), and the Si doping concentration is 5.1×10 19 / cm 3 , the carrier mobility is 1600cm 2 / (vs.). In order, ultrasonic cleaning was performed with AR grade acetone, ethanol and ultrapure water for 5 minutes, followed by rinsing with 6% hydrochloric acid for 3 minutes, and then rinsing with deionized water.

[0039] (2) Graphene transfer: Graphene is a single-layer graphene grown on a copper base, and the preparation method is a conventional CVD method (refer to Dervishi E, Li Z, Watanabe F, et al.Large-scale graphene production by RF-cCVD method[J].Chemical Communications, 2009(27):4061.), before transferring, graphene needs to be transferred to ferric chloride solution of 1mol / L, after the copper metal substrate is completely dissolved, use PMMA accompanying sheet to transfer graphite The alkene was transferred in ultrapure water three times, each time for 3 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com