High temperature resistant crosslinked acid system for acid fracturing and preparation method thereof

A technology of high temperature resistance and cross-linking acid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of large acid liquid filtration, fast reaction speed of acid rock, affecting the effect of acid fracturing, etc., and achieves dissolution speed Fast, achieve acid fracturing transformation, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of above-mentioned high temperature resistant crosslinking acid thickener is as follows:

[0029] ① Add acrylamide monomer (AM): 2-acrylamide-2-methylpropanesulfonic acid (AMPS) according to the mass ratio of 2:1~2, add it to the modulation reactor and mix it, and use NaOH to adjust the pH value to 11-12 ;

[0030] ②Pump the mixed reactants in the modulation reactor into the polymerization reactor, add the catalyst azobisisobutyronitrile, and use nitrogen to keep the temperature between 0-8°C;

[0031] ③ Under the condition of stirring, slowly add dimethyl diallyl ammonium chloride, pay attention to observe the temperature change, control the reaction temperature within 10 ℃, and continue the reaction for 4 hours, and the slow-release acid thickener is AM-AMPS copolymerization substance, molecular weight 6-15 million;

[0032] ④ Pressurize with nitrogen, extrude the reaction product, use a crusher for primary crushing, and the particle size is a...

Embodiment 1

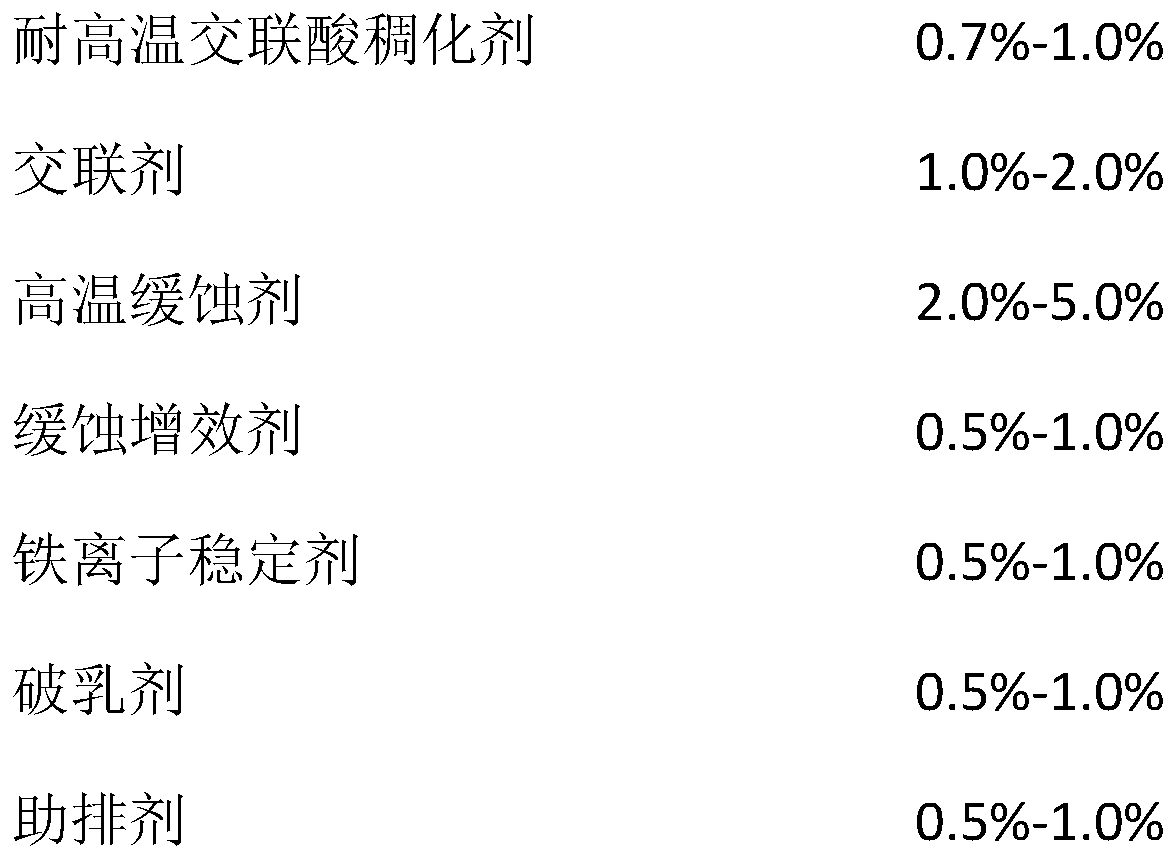

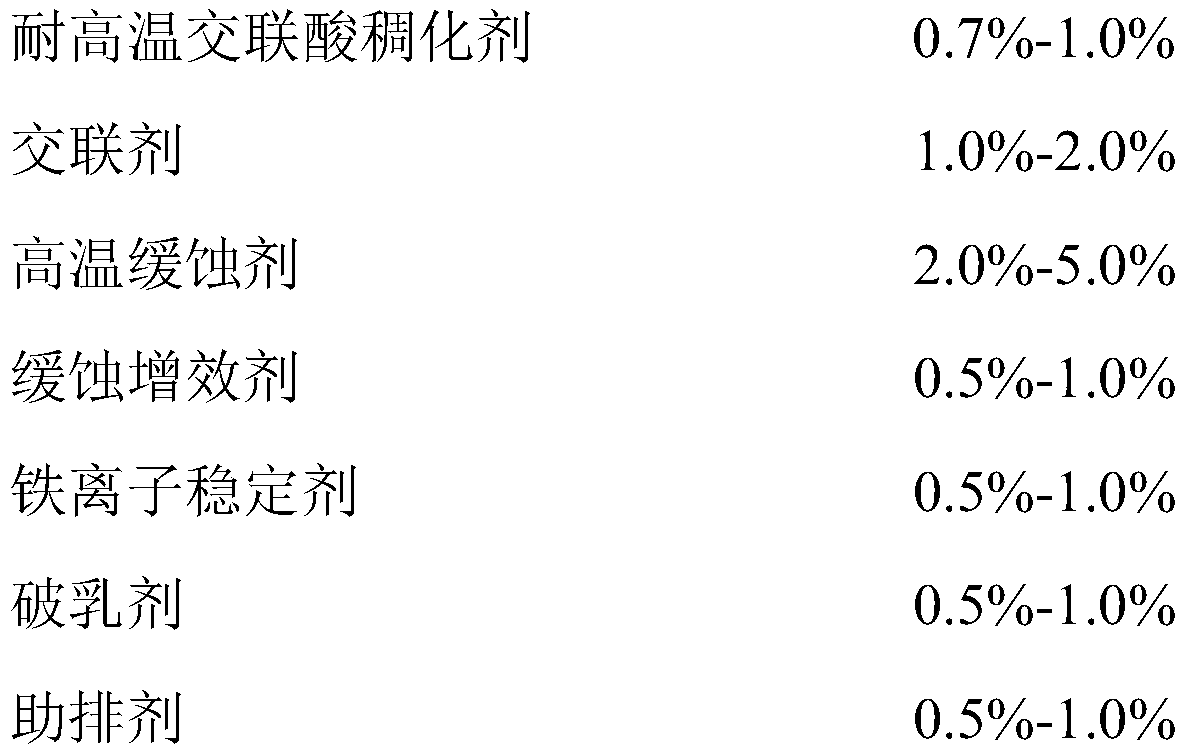

[0040] Acid compression high temperature resistant cross-linked acid system, the mass percentage of raw materials is as follows:

[0041] High temperature resistant crosslinking acid thickener 0.7%

[0042] Cross-linking agent 1.0%

[0043] High temperature corrosion inhibitor 2.0%

[0044] Iron ion stabilizer 1.0%

[0045] Drainage aid 1.0%

[0046] The balance is hydrochloric acid with a mass fraction of 20%.

[0047] Among them, the mass ratio of monomer acrylamide (AM) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in the high temperature resistant crosslinking acid thickener is 3:1.5, and the molecular weight of the thickener is 11 million.

[0048] The crosslinking agent is zirconate.

[0049] The high temperature corrosion inhibitor is a mixture of Mannich base, methanol and water with a mass ratio of 45:40:15.

[0050] Described iron ion stabilizer is sodium citrate.

[0051] The demulsifier is polyoxyethylene polyoxypropylene polyether.

[0052] The drai...

Embodiment 2

[0056] Acid compression high temperature resistant cross-linked acid system, the mass percentage of raw materials is as follows:

[0057] High temperature resistant crosslinking acid thickener 0.8%

[0058] Cross-linking agent 2.0%

[0059] High temperature corrosion inhibitor 3.0%

[0060] Iron ion stabilizer 1.0%

[0061] Drainage aid 1.0%

[0062] The balance is hydrochloric acid with a mass fraction of 20%.

[0063] Among them, the mass ratio of monomer acrylamide (AM) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in the high temperature resistant crosslinking acid thickener is 2:1.5, and the molecular weight of the thickener is 12 million.

[0064] The crosslinking agent is zirconate.

[0065] The high temperature corrosion inhibitor is a mixture of Mannich base, methanol and water with a mass ratio of 45:40:15.

[0066] The corrosion inhibition synergist is antimony oxide.

[0067] Described iron ion stabilizer is sodium citrate.

[0068] The demulsifier i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com