Wear-resistant and corrosion-resistant spray coating on valve flow surface and preparation method thereof

A flow-through surface and corrosion-resistant technology, applied in coatings, metal material coating processes, molten spraying, etc., can solve problems such as insufficient wear and corrosion resistance, high brittleness of sprayed materials, and large tendency to fall off. To achieve the effect of prolonging the service life, improving the brittleness and good powder fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

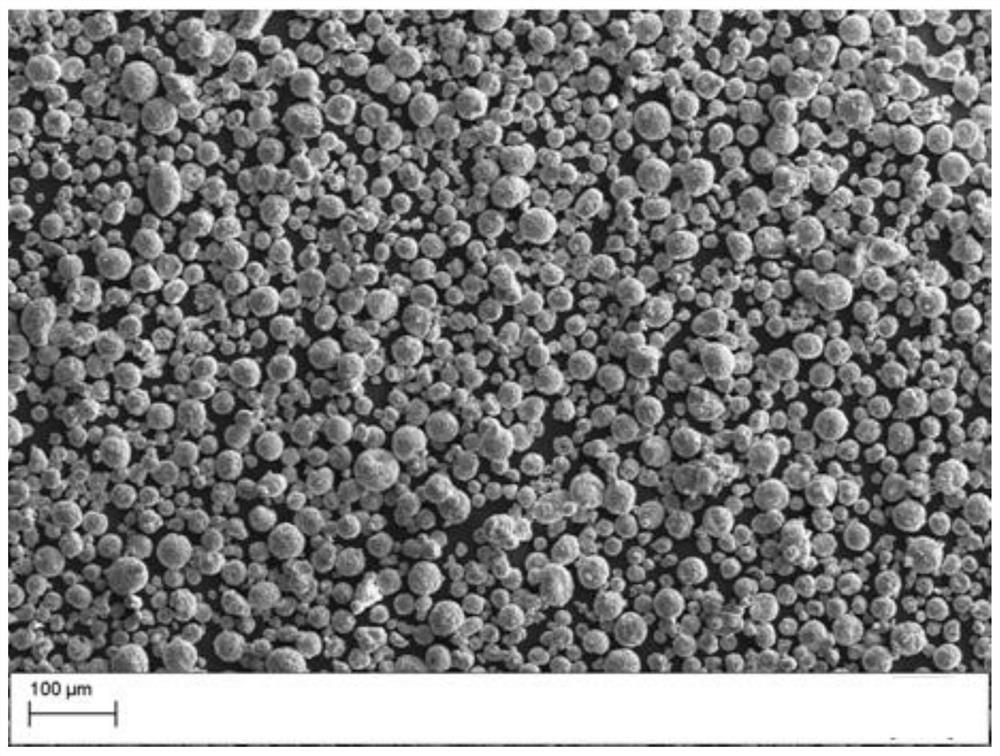

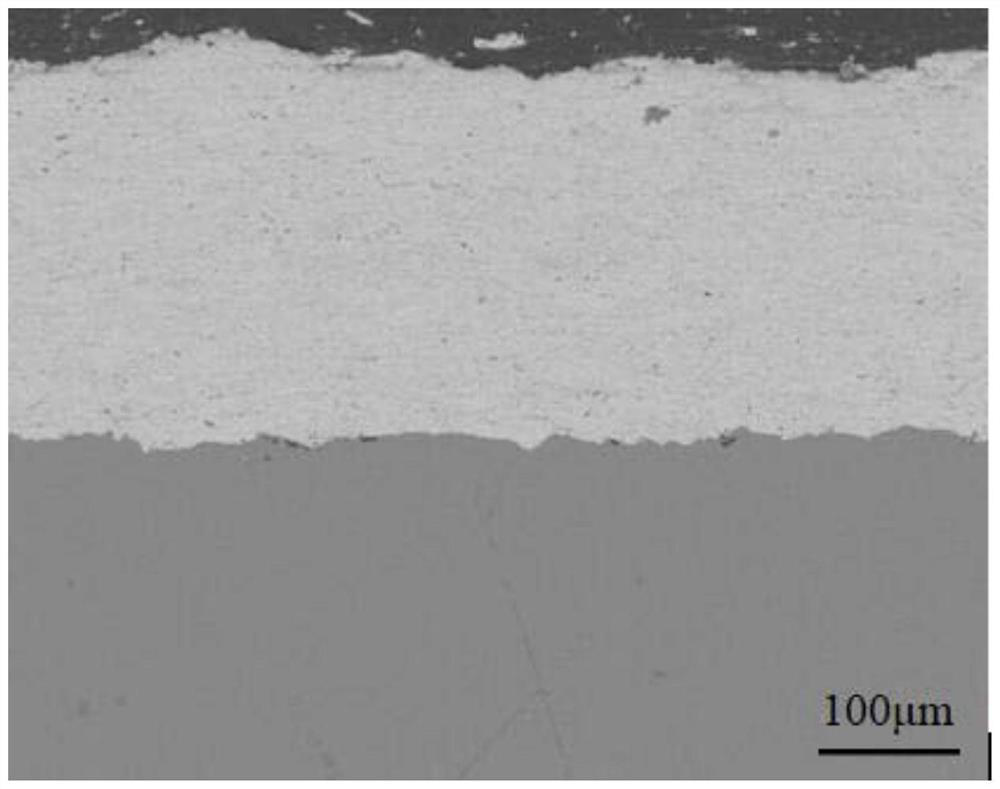

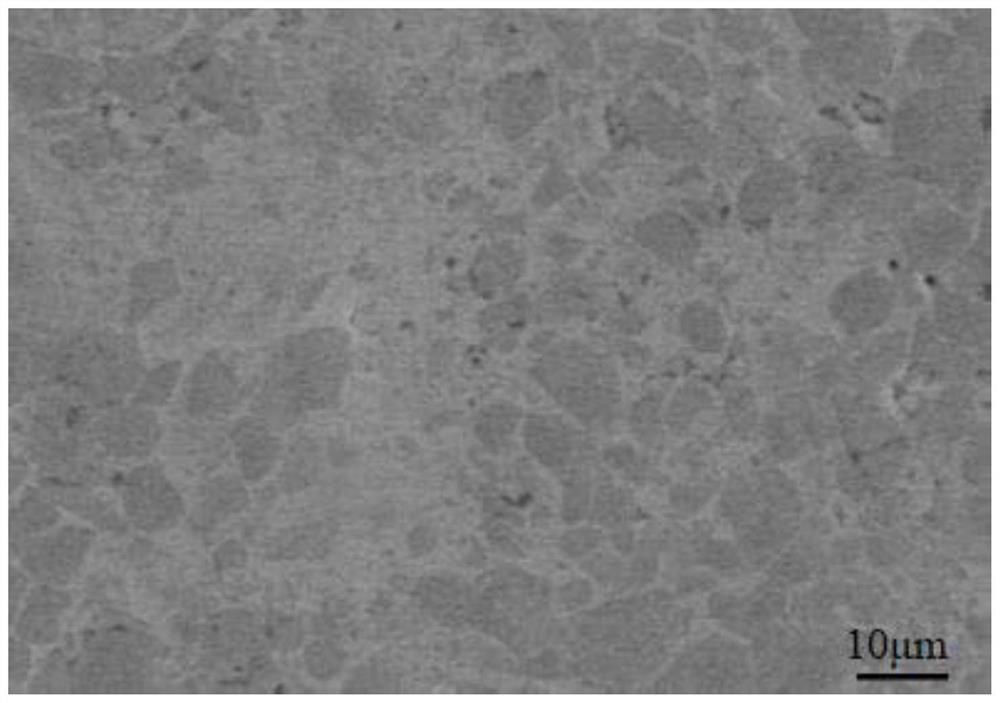

[0031] A wear-resistant and corrosion-resistant spray coating on the overflow surface of a valve and its preparation method and its preparation method. The wear-resistant and corrosion-resistant spray coating includes the following components: powder, adhesive and dispersant, powder, adhesive The weight ratio with the dispersant is 100:2:2; the powder includes the following weight percentage components: nickel powder 10%, chromium powder 5%, and the balance is composite solid solution powder; the composite solid solution powder includes the following weight percentage components: carbon 8%, nitrogen 7%, tungsten 10%, molybdenum 5%, vanadium 5%, and the balance is titanium. The particle size of nickel powder, chromium powder and composite solid solution powder is 1-2.5 μm; the binder is polyvinyl alcohol, and the dispersant is n-heptane.

[0032] The preparation method of the above-mentioned wear-resistant and corrosion-resistant spray coating on the flow-through surface of the...

Embodiment 2

[0039]A wear-resistant and corrosion-resistant spray coating on the overflow surface of a valve and its preparation method and its preparation method. The wear-resistant and corrosion-resistant spray coating includes the following components: powder, adhesive and dispersant, powder, adhesive The weight ratio with the dispersant is 100:4:3; the powder includes the following components in weight percent: nickel powder 20%, chromium powder 10%, and the balance is composite solid solution powder; the composite solid solution powder includes the following components in weight percent: carbon 9%, nitrogen 8%, tungsten 13%, molybdenum 10%, vanadium 8%, and the balance is titanium. The particle size of nickel powder, chromium powder and composite solid solution powder is 1-2.5 μm; the binder is polyvinyl alcohol, and the dispersant is n-heptane.

[0040] The preparation method of the above-mentioned wear-resistant and corrosion-resistant spray coating on the flow-through surface of th...

Embodiment 3

[0047] A wear-resistant and corrosion-resistant spray coating on the overflow surface of a valve and its preparation method and its preparation method. The wear-resistant and corrosion-resistant spray coating includes the following components: powder, adhesive and dispersant, powder, adhesive The weight ratio with the dispersant is 100:5:4; the powder includes the following components in weight percent: 30% nickel powder, 15% chromium powder, and the balance is composite solid solution powder; the composite solid solution powder includes the following components in weight percent: carbon 10%, nitrogen 10%, tungsten 15%, molybdenum 15%, vanadium 10%, and the balance is titanium. The particle size of nickel powder, chromium powder and composite solid solution powder is 1-2.5 μm; the binder is polyvinyl alcohol, and the dispersant is n-heptane.

[0048] The preparation method of the above-mentioned wear-resistant and corrosion-resistant spray coating on the flow-through surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com