Method for improving germanium leaching rate of germanium-rich zinc suboxide smoke dust

A technology of secondary zinc oxide and leaching rate, which is applied in the field of improving germanium leaching rate of germanium-rich sub-zinc oxide soot, can solve the problems of germanium leaching rate decrease, germanium recovery difficulty, and low germanium leaching rate cannot be changed, so as to improve germanium leaching rate , The effect of improving the leaching rate of germanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

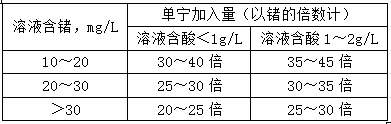

Method used

Image

Examples

Embodiment 1

[0044] The main components of the germanium-rich zinc oxide dust used in this example are: Zn: 45.39%, Pb: 18.43%, acid-soluble SiO 2 : 2.87%, Ge: 0.0741%.

[0045] (1) Slurry: Take 500g of germanium-rich sub-zinc oxide dust and slurry it with water.

[0046](2) One-stage leaching: Add dilute sulfuric acid to 3 acid addition points with an adjustable flow metering pump until the pH value of the slurry is ≈4.0, and keep the pH value for 0.5 hours to dissolve the zinc.

[0047] (3) Second-stage leaching: continue to add dilute sulfuric acid at 3 points, control the pH value of the pulp ≈ 3.5, and keep the pH value for 0.5 hours to react; the silicate is dissolved, and the silicon dioxide that enters the solution is dissolved at the same time, and then the hydrated silicon protein ( SiO 2 .nH 2 O) Morphological precipitation into slag.

[0048] (4) Three-stage leaching: Continue to add dilute sulfuric acid at 3 points until the pH value of the slurry is ≈3.0, and keep this pH...

Embodiment 2

[0054] The main components of the germanium-rich zinc oxide dust used in this example are: Zn: 49.85%, Pb: 21.09%, acid-soluble SiO 2 : 4.03%, Ge: 0.0956%.

[0055] (1) Slurry: Take 500g of germanium-rich sub-zinc oxide dust and slurry it with water.

[0056] (2) One-stage leaching: Add dilute sulfuric acid to 4 acid addition points with an adjustable flow metering pump until the pH value of the slurry is ≈4.5, and keep the pH value for 1.0h to dissolve the zinc.

[0057] (3) Second-stage leaching: continue to add dilute sulfuric acid at 4 o'clock, control the pH value of the pulp ≈ 4.0, and keep this pH value for 1.0 hours of reaction; the silicate is dissolved, and the silicon dioxide that enters the solution is dissolved at the same time, and then hydrated silicon protein (SiO 2 .nH 2 O) Morphological precipitation into slag.

[0058] (4) Three-stage leaching: Continue to add dilute sulfuric acid at 4 o'clock until the pH value of the slurry is ≈2.5, and keep this pH va...

Embodiment 3

[0064] The main components of the germanium-rich zinc oxide dust used in this example are: Zn: 55.26%, Pb: 13.38%, acid-soluble SiO 2 : 5.31%, Ge: 0.117%.

[0065] (1) Slurry: Take 500g of germanium-rich sub-zinc oxide dust and slurry it with water.

[0066] (2) One-stage leaching: Use an adjustable flow metering pump to add zinc electrolysis waste liquid at 5 acid addition points until the pH value of the slurry is ≈4.0, and keep the pH value for 1.5 hours to dissolve the zinc.

[0067] (3) Second-stage leaching: continue to add zinc electrolytic waste liquid at 5 o'clock, control the pH value of the ore pulp ≈ 3.5, and keep this pH value for reaction for 1.5 hours; the silicate is dissolved, and the silicon dioxide that enters the solution is dissolved at the same time and then hydrated Silicon protein (SiO 2 .nH 2 O) Morphological precipitation into slag.

[0068] (4) Three-stage leaching: continue to add zinc electrolytic waste solution at 5 o'clock until the pH value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com