Preparation method of starch and low-polylactic acid graft copolymer

A technology of graft copolymer and oligomeric lactic acid is applied in the field of preparation of starch and oligomeric lactic acid graft copolymer, which can solve the problems of poor compatibility and ductility, high product cost and high crystallinity, and achieve compatibility High, low cost, easy to process and form the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

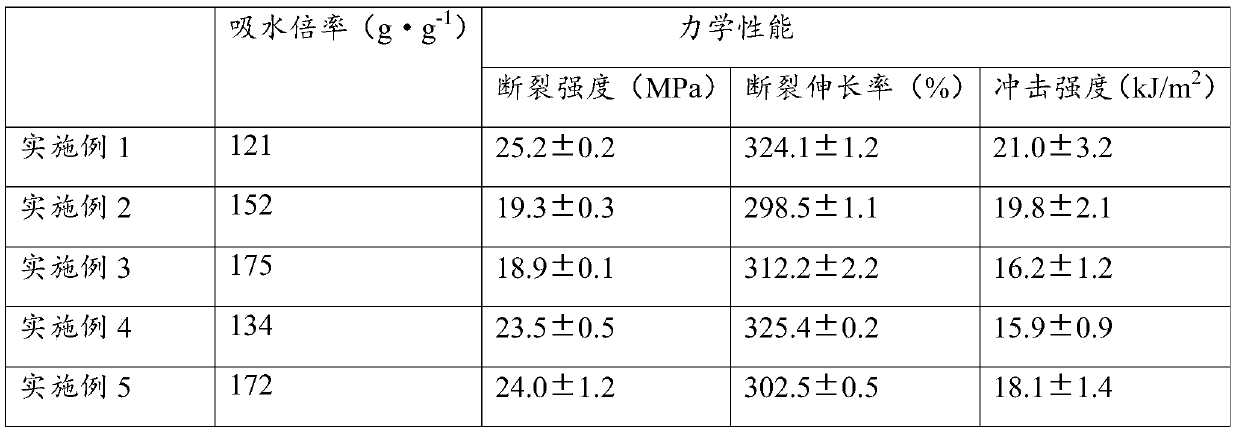

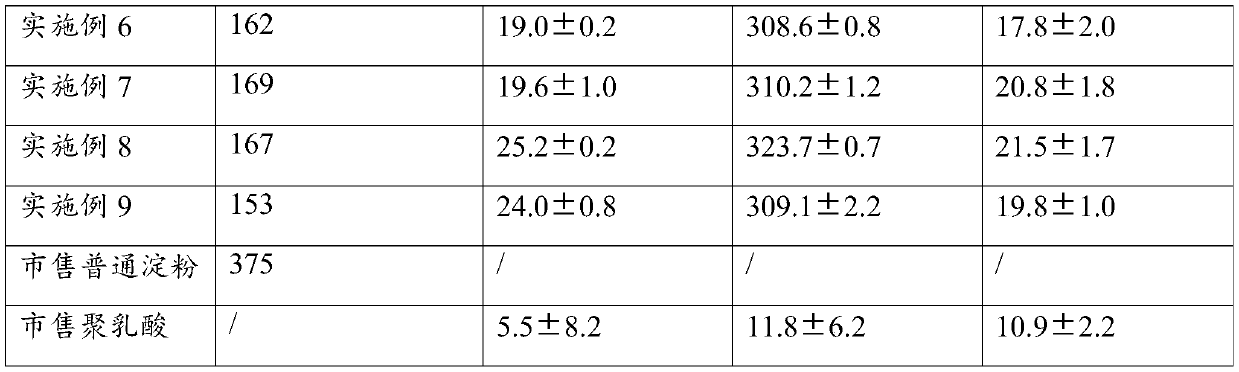

Examples

preparation example Construction

[0015] Specifically, the preparation method of the starch and oligomeric lactic acid graft copolymer comprises the following steps:

[0016] 50-100 parts by weight of the starch reaction product, 50-100 parts by weight of the oligomeric lactic acid reaction product and 1-5 parts by weight of the polybasic organic acid are put into a high-speed mixer and mixed for 5-30 minutes to obtain the first mixture;

[0017] Add 0.5-2 parts by weight of graft monomer and 0.1-1 part by weight of initiator to the first mixture, react and mix at 100-200°C for 30-150 minutes to obtain a second mixture;

[0018] Add 0.5-2 parts by weight of bio-lubricant and 0.2-2 parts by weight of bio-enhancer into the second mixture, mix them evenly, and then add them to a parallel co-phase twin-screw extruder for plasticization and granulation at a temperature of 90-200 ℃, that is.

[0019] In the embodiment of the present invention, the starch reaction product is a modified product of starch. The specifi...

Embodiment 1

[0034] A kind of preparation method of starch and oligomeric lactic acid graft copolymer, comprising:

[0035] 100 parts by weight of the starch reaction product, 100 parts by weight of the oligomeric lactic acid reaction product and 5 parts by weight of itaconic acid were put into a high mixer and mixed for 30 minutes to obtain the first mixture;

[0036] Add 2 parts by weight of acrylic acid and 1 part by weight of ammonium cerium nitrate to the first mixture, and react and mix at 200°C for 150 minutes to obtain the second mixture;

[0037] 2 parts by weight of stearic acid and 2 parts by weight of butyl acrylate were added to the second mixture, mixed evenly, and then added to a parallel co-phase twin-screw extruder for plasticization and granulation at a temperature of 200°C to obtain the product.

[0038] Wherein, the preparation method of described starch reaction product is:

[0039] 100 parts by weight of tapioca starch, 50 parts by weight of water and 2 parts by weig...

Embodiment 2

[0044] A kind of preparation method of starch and oligomeric lactic acid graft copolymer, comprising:

[0045]60 parts by weight of the starch reaction product, 60 parts by weight of the oligomeric lactic acid reaction product and 2 parts by weight of tartaric acid were put into a high mixer and mixed for 8 minutes to obtain the first mixture;

[0046] Add 0.8 parts by weight of maleic anhydride and 0.3 parts by weight of potassium permanganate to the first mixture, and react and mix at 120°C for 50 minutes to obtain the second mixture;

[0047] Add 0.8 parts by weight of stearylamide and 0.8 parts by weight of butyl methacrylate to the second mixture, mix them uniformly, and then add them to a parallel co-phase twin-screw extruder for plasticization and granulation at a temperature of 120°C to obtain .

[0048] Wherein, the preparation method of described starch reaction product is:

[0049] 100 parts by weight of potato starch, 20 parts by weight of water and 0.9 parts by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com