Method for recycling boron carbide in ground waste slurry and application method of recycled boron carbide

A technology of boron carbide and waste slurry, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of inconvenient wastewater treatment and rising costs, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

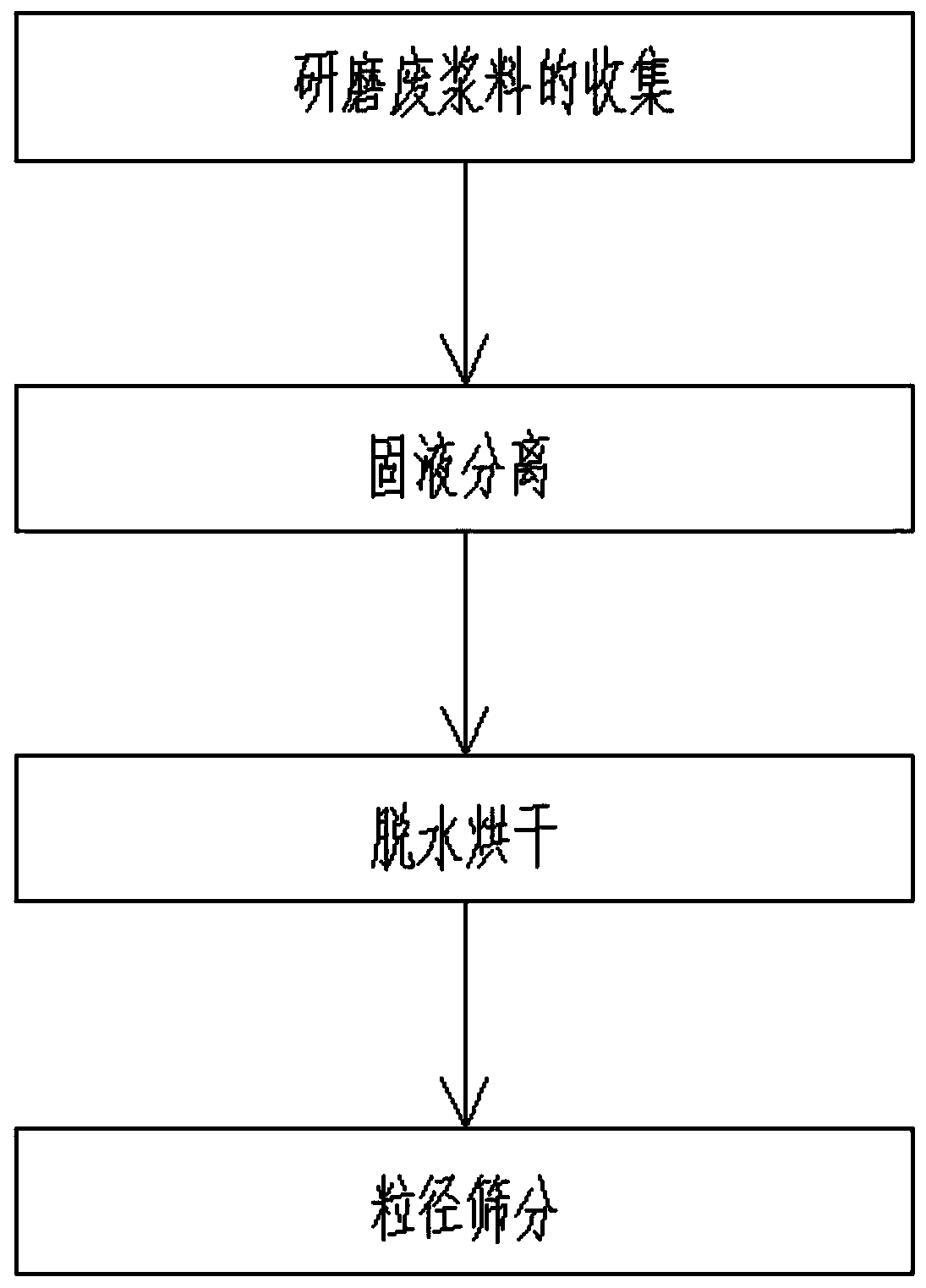

[0058] refer to figure 2 , a kind of method that the present invention provides the boron carbide recycling in grinding waste slurry, comprises the following steps:

[0059] Step 1, the collection of grinding waste slurry:

[0060] Collect the waste slurry after the sapphire grinding process in barrels;

[0061] Step 2, solid-liquid separation:

[0062] The grinding waste slurry collected in step 1 is subjected to solid-liquid separation, and after precipitation, the lower layer powder at the bottom is extracted for later use; wherein, the method of solid-liquid separation is gravity precipitation method, and the precipitation time is 30 minutes;

[0063] Step 3, dehydration and drying:

[0064] Extract the lower layer powder in step 2 to a dehydrator for dehydration and drying to obtain waste old dry powder with a moisture content of 10%; the dehydrator speed is 600rpm, the dehydration time is 10min, and the baking temperature is 80°C. The time is 120min;

[0065] Step ...

Embodiment 2

[0071] refer to figure 2 , a method for recycling boron carbide in grinding waste slurry, comprising the following steps:

[0072] Step 1, the collection of grinding waste slurry:

[0073] Collect the waste slurry after the sapphire grinding process in barrels;

[0074] Step 2, solid-liquid separation:

[0075] The grinding waste slurry collected in step 1 was subjected to solid-liquid separation, and after precipitation, the lower layer powder at the bottom was extracted for later use; wherein, the method of solid-liquid separation was gravity precipitation, and the precipitation time was 45 minutes;

[0076] Step 3, dehydration and drying:

[0077] Extract the lower layer powder in step 2 to a dehydrator for dehydration and drying to obtain waste old dry powder with a moisture content of 8%; wherein the dehydrator rotates at 1300rpm, the dehydration time is 15min, and the baking temperature is 100°C. The time is 135min;

[0078] Step 4, particle size screening:

[007...

Embodiment 3

[0084] refer to figure 2 , a method for recycling boron carbide in grinding waste slurry, comprising the following steps:

[0085] Step 1, the collection of grinding waste slurry:

[0086] Collect the waste slurry after the sapphire grinding process in barrels;

[0087] Step 2, solid-liquid separation:

[0088] The waste grinding slurry collected in step 1 is subjected to solid-liquid separation, and after precipitation, the lower layer powder at the bottom is extracted for later use; wherein, the method of solid-liquid separation is gravity precipitation, and the precipitation time is 60 minutes;

[0089] Step 3, dehydration and drying:

[0090] Extract the lower layer powder in step 2 to a dehydrator for dehydration and drying to obtain waste old dry powder with a moisture content of 5%. The dehydrator rotates at 2000rpm, the dehydration time is 20min, and the baking temperature is 120°C. The time is 150min;

[0091] Step 4, particle size screening:

[0092] Place the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com