Ocean engineering corrosion prevention polyurea coating and preparation method thereof

A technology of marine engineering and polyurea, which is applied in anti-corrosion coatings, polyurea/polyurethane coatings, anti-fouling/underwater coatings, etc., and can solve the problems of unsatisfactory bonding force between anti-corrosion polyurea coatings and metal structures and unsatisfactory anti-corrosion effects , to achieve the effect of strong reciprocating force, strong antibacterial effect, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation of embodiment 1 modified nanometer titanium dioxide

[0051] Disperse 50 parts of nano-titanium dioxide in a hydrogen peroxide solution with a concentration of 25%, stir for 30 minutes, filter, wash with acetone, and dry; disperse the dried nano-titanium dioxide in water, add 5 parts of surfactant triethanolamine, Adjust pH to 5.0, add 3 parts of silane coupling agent KH560, ultrasonically disperse evenly, dropwise add silver nitrate solution and copper sulfate solution to a final concentration of 0.05mol / L, after the dropwise addition is completed, the temperature is raised to 90 ° C, stirred for 25 minutes, decreased to room temperature, centrifugation and drying to obtain modified nano-titanium dioxide.

Embodiment 2

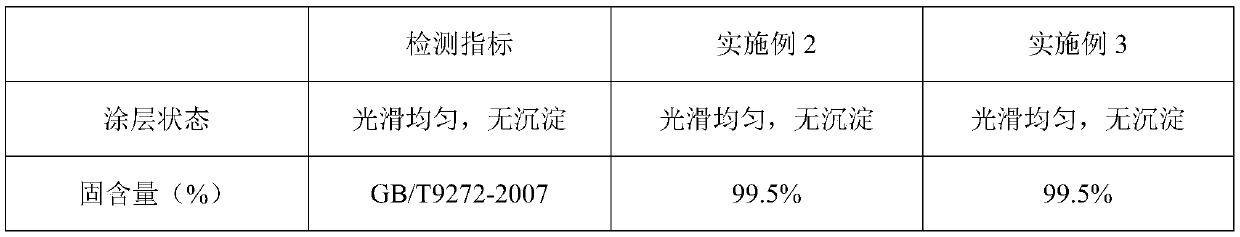

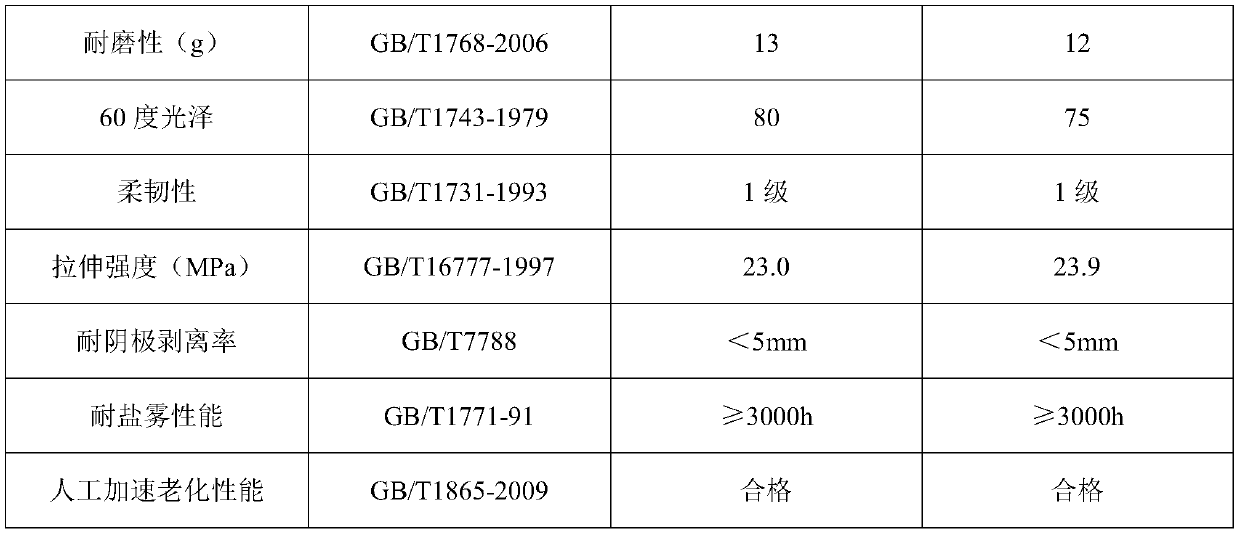

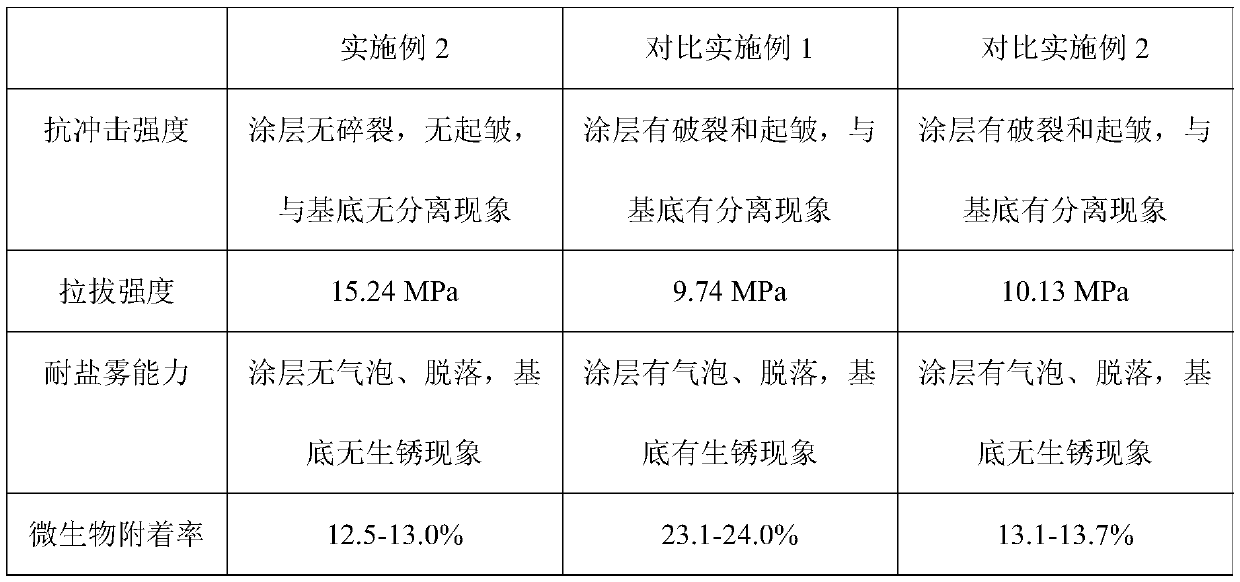

[0055] The preparation of embodiment 2 anti-corrosion polyurea coating

[0056] S1: Dehydrate 34 parts of polycarbonate diol at 120° C. and vacuum degree of -0.08Mpa for 2 hours, and then lower it to room temperature for use;

[0057] S2: put 66 parts of diphenyltoluene diisocyanate into the reaction kettle, heat up to 45°C, slowly add polycarbonate diol dropwise, heat up to 80°C after the dropwise addition, keep the temperature for 2 hours, take a sample to measure the NCO content, when the NCO When the content is 19.0%, it is lowered to room temperature, filtered, and sealed with nitrogen for storage for later use;

[0058] S3: Put 34 parts of amino-terminated polyether D2000 into the stirring tank, add 30 parts of diethyltoluenediamine, 10 parts of 4,4-bis-sec-butylaminodiphenylmethane, stir for 0.5 hour, add hydroxyethyl ethylene diamine 5 parts of amine triacetic acid, 8 parts of Sea-Nine211, 14.7 parts of composite zinc-aluminum phosphate, 0.3 part of fumed silica, and ...

Embodiment 3

[0059] The preparation of embodiment 3 anticorrosion polyurea coating

[0060] S1: dehydrate 50 parts of polycarbonate diol at 110° C. and vacuum degree of -0.08Mpa for 2 hours, and then lower it to room temperature for use;

[0061] S2: Put 70 parts of diphenyltoluene diisocyanate into the reaction kettle, heat up to 50°C, slowly add polycarbonate diol dropwise, heat up to 80°C after the dropwise addition, keep the temperature for 2 hours, take samples to measure the NCO content, when the NCO When the content is 20.0%, it is lowered to room temperature, filtered, and sealed with nitrogen for storage for later use;

[0062] S3: Put 40 parts of amino-terminated polyether T5000 into the mixing tank, add 30 parts of diethyltoluenediamine, 10 parts of 4,4-bis-sec-butylaminodiphenylmethane, stir for 0.5 hour, add dihydroxyethylglycine 5 parts, 10 parts of Sea-Nine211, 17 parts of composite zinc-aluminum phosphate, 0.5 part of fumed silica, then added 4 parts of modified nano-titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com