Weak-luminescence g-C3N4 photocatalyst and preparation method and application thereof

A photocatalyst, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of low specific surface area, application limitation, low photocatalytic efficiency, etc., and achieve the effect of stable chemical properties and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

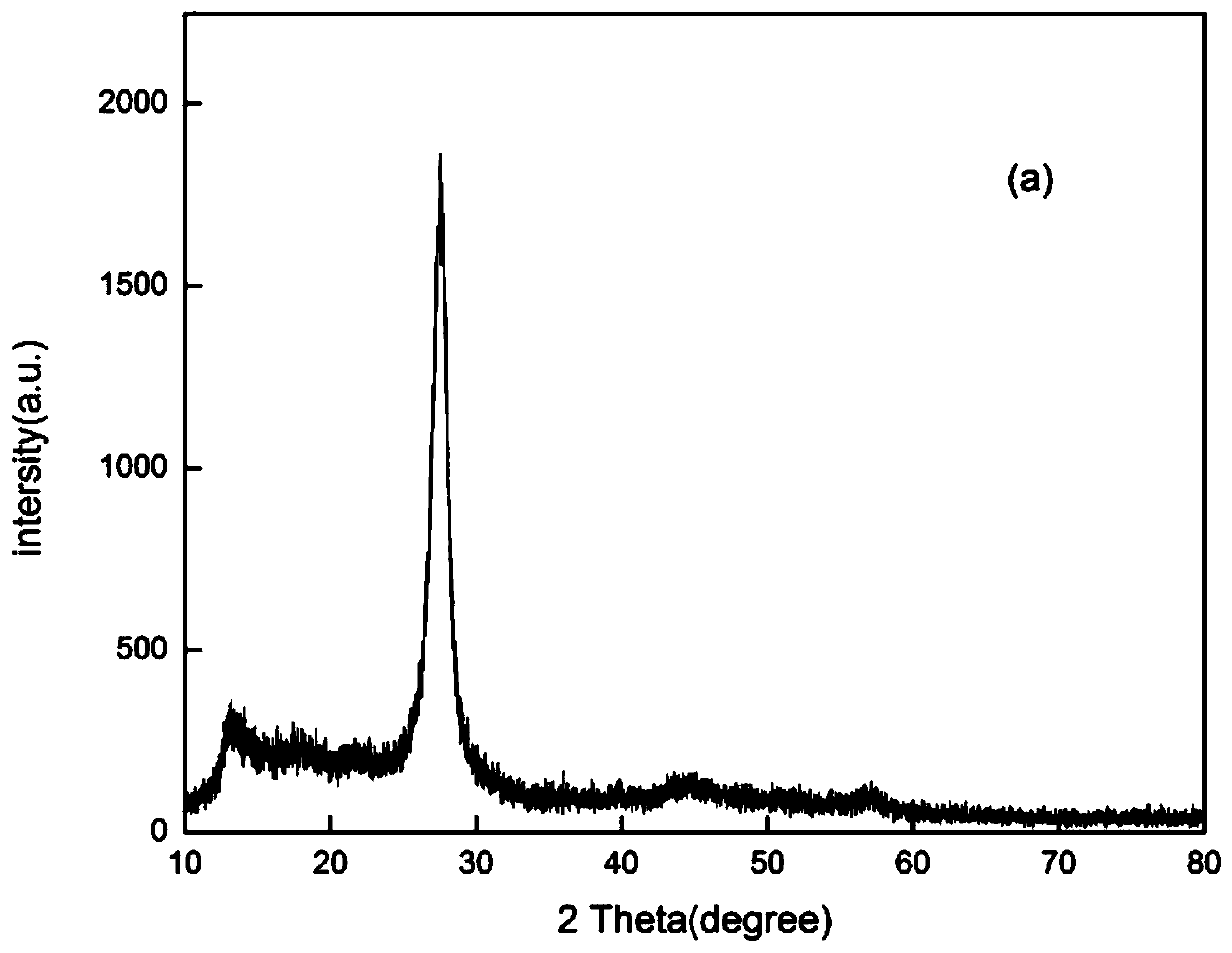

[0024] (1) Pure g-C 3 N 4 catalyst of light

[0025] Preparation method: Measure 2.52 grams of melamine into an alumina crucible, transfer it to a muffle furnace, and roast it at 550 °C for 4 hours in an air atmosphere (the heating rate is 5 °C min -1 ), to obtain pure g-C 3 N 4 catalyst of light.

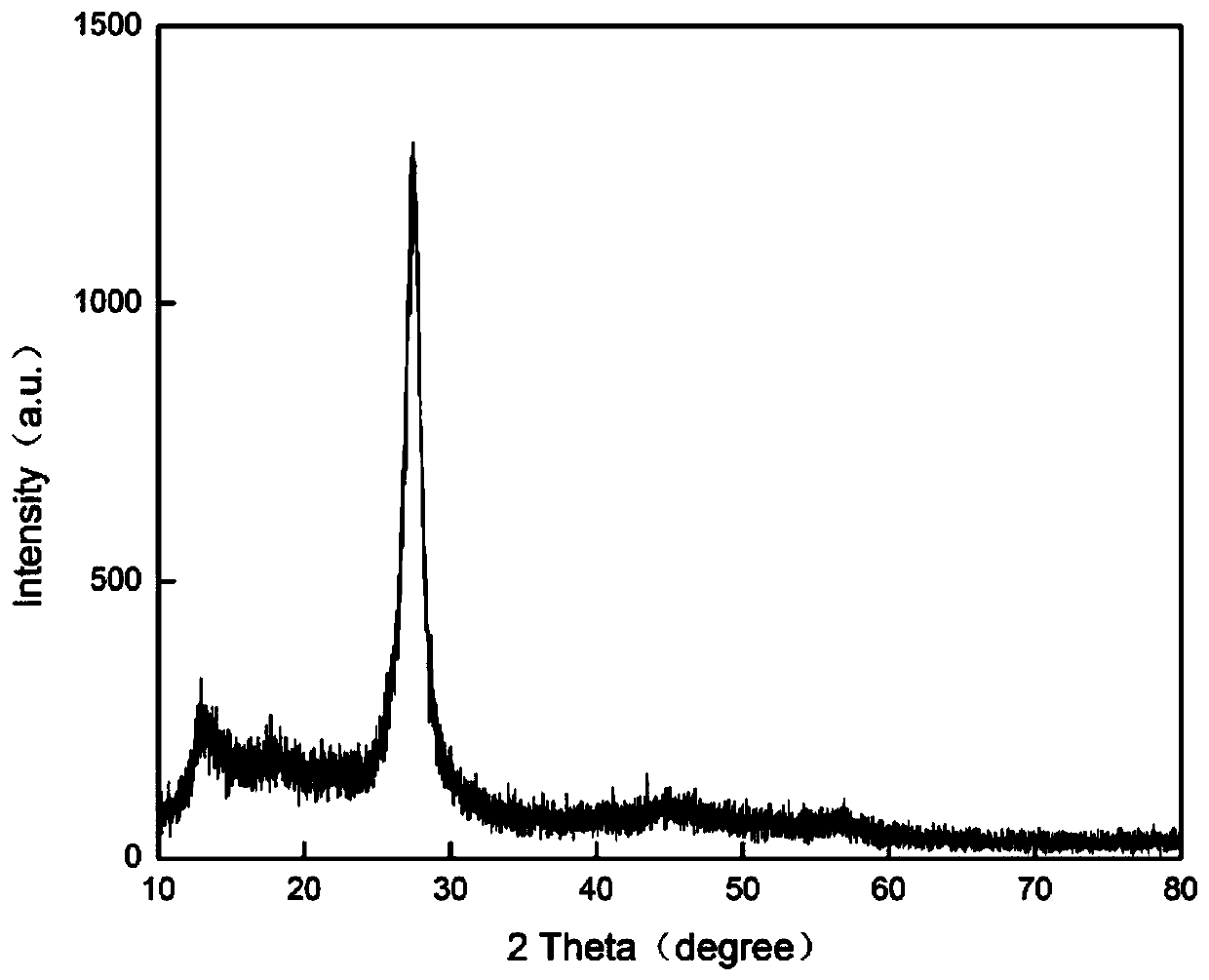

[0026] (2) Weak luminescence g-C 3 N 4 catalyst of light

[0027] Add 2.52 g (0.02 mol) of solid melamine into 100 ml of 50% (v / v) ethanol solution, stir in a water bath at 60° C. for 30 min until it dissolves uniformly. Add 0.0122g of benzoic acid (0.001mol) into 20ml of absolute ethanol, stir for 20min until it dissolves evenly, then add dropwise into the ethanol solution of melamine. Stir in a water bath at 60°C for 2h, and sonicate for 30min. The obtained product was transferred to an oven and dried at 70° C. for 12 hours to obtain a white intermediate product. Grind the obtained white intermediate product, put it into an alumina crucible, transfer it to a muffle furn...

Embodiment 2

[0035] The Molar Ratio of Melamine and Benzoic Acid Effect on Weak Luminescence g-C 3 N 4 Effect of Photocatalyst on Catalytic Degradation of Rhodamine B under Visible Light

[0036] (1) Weakly emitting g-C with different molar ratios 3 N 4 Preparation of photocatalyst

[0037] Table 1

[0038]

[0039] The preparation method is as follows: add 2.52 g (0.02 mol) of melamine solid into 100 ml of 50% (v / v) ethanol solution, stir in a water bath at 60° C. for 30 min until it is uniformly dissolved. As shown in Table 1, add benzoic acid into 20ml of absolute ethanol, stir for 20min until it dissolves evenly, and then add it dropwise into the ethanol solution of melamine. Stir in a water bath at 60°C for 2h, and sonicate for 30min. The obtained product was transferred to an oven and dried at 70° C. for 12 hours to obtain a white intermediate product. Grind the obtained white intermediate product, put it into an alumina crucible, transfer it to a muffle furnace, and bake i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com