Lithium lanthanum titanate composite material and preparation method thereof, and lithium ion solid state battery

A composite material and solid-state battery technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, etc., can solve the problems of low total conductivity, achieve simple preparation process, improve total ion conductance, and high material density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

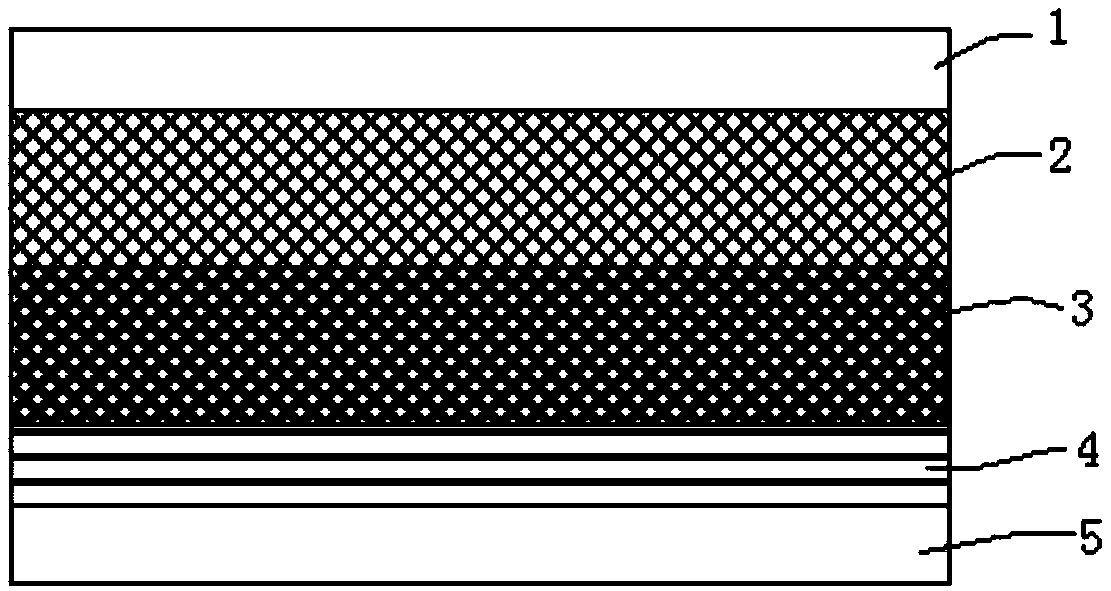

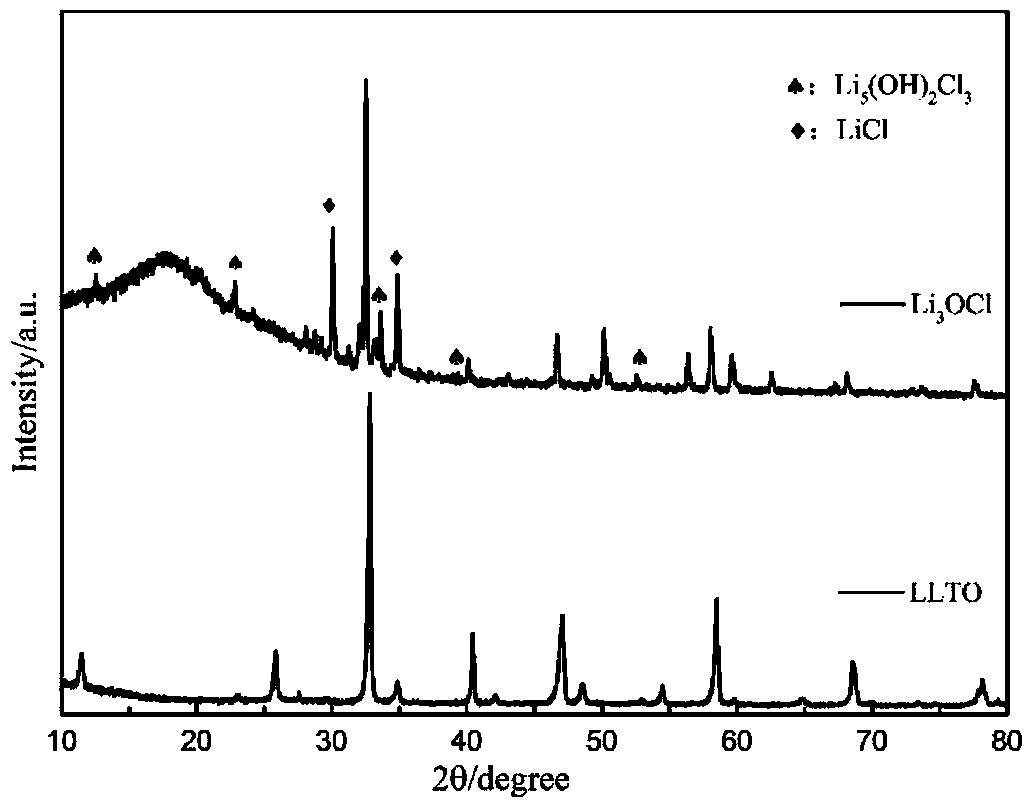

[0036] The lithium titanate lanthanum composite material of the present embodiment is made of Li 0.5 La 0.5 TiO 3 and Li 3 OCl is compounded, and the structure diagram is as follows figure 1 As shown, Li 3 OX is distributed at the grain boundary between lithium lanthanum titanate grains, and part of Li 3 OX also diffuses into the grains of lithium lanthanum titanate; Li 0.5 La 0.5 TiO 3 and Li 3 The mass ratio of OCl is 9.99:0.01.

[0037] The preparation method of the lithium lanthanum titanate composite material of the present embodiment adopts the following steps: 9.99gLi 0.5 La 0.5 TiO 3 and 0.01g Li 3 Grind and mix OCl, weigh 1g of the mixed powder, and press it into a tablet in a mold with a diameter of 16mm. The pressure during pressing is 20MPa, and the holding time is 2min. Lithium lanthanum titanate composite.

[0038] The lithium-ion solid-state battery of this embodiment has a structural schematic diagram as figure 2 As shown, it includes a positive...

Embodiment 2

[0044] The structure of the lithium lanthanum titanate composite material of this embodiment is basically the same as that of Example 1, the only difference being that Li 0.5 La 0.5 TiO 3 and Li 3 The mass ratio of OCl is 9.985:0.015.

[0045] The preparation method of the lithium lanthanum titanate composite material in this embodiment is prepared with reference to Example 1.

[0046] The lithium-ion solid-state battery of this embodiment was prepared with reference to Example 1.

Embodiment 3

[0048] The structure of the lithium lanthanum titanate composite material of this embodiment is basically the same as that of Example 1, the only difference being that Li 0.5 La 0.5 TiO 3 and Li 3 The mass ratio of OCl is 9.98:0.02.

[0049] The preparation method of the lithium lanthanum titanate composite material in this example is basically the same as that in Example 1, except that the calcination condition is 1100° C. for 7 hours.

[0050] The lithium-ion solid-state battery of this embodiment is basically the same as that of Embodiment 1, the only difference being that the thickness of the positive active material layer is 30 μm, and the active material layer is made of positive active material, conductive carbon black, PVDF and lithium lanthanum titanate composite material Composition, the mass ratio of each component is 91:3:3:3; the thickness of the solid electrolyte layer on the active material layer is 35 μm, and the mass ratio of lithium lanthanum titanate comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com