Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as circuit short circuit, semiconductor device yield reduction, barrier dielectric layer deposition, etc., to achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

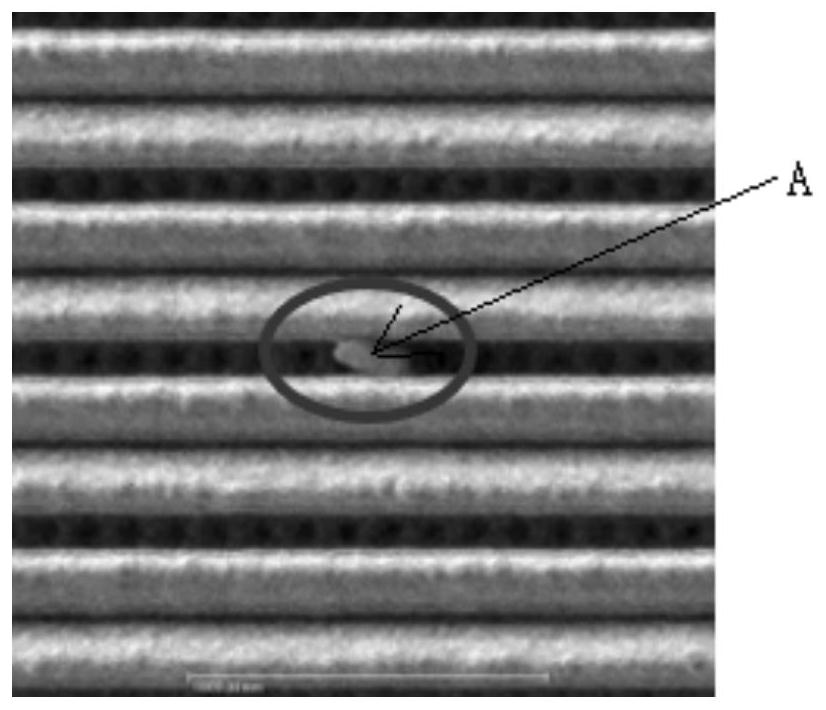

Image

Examples

Embodiment Construction

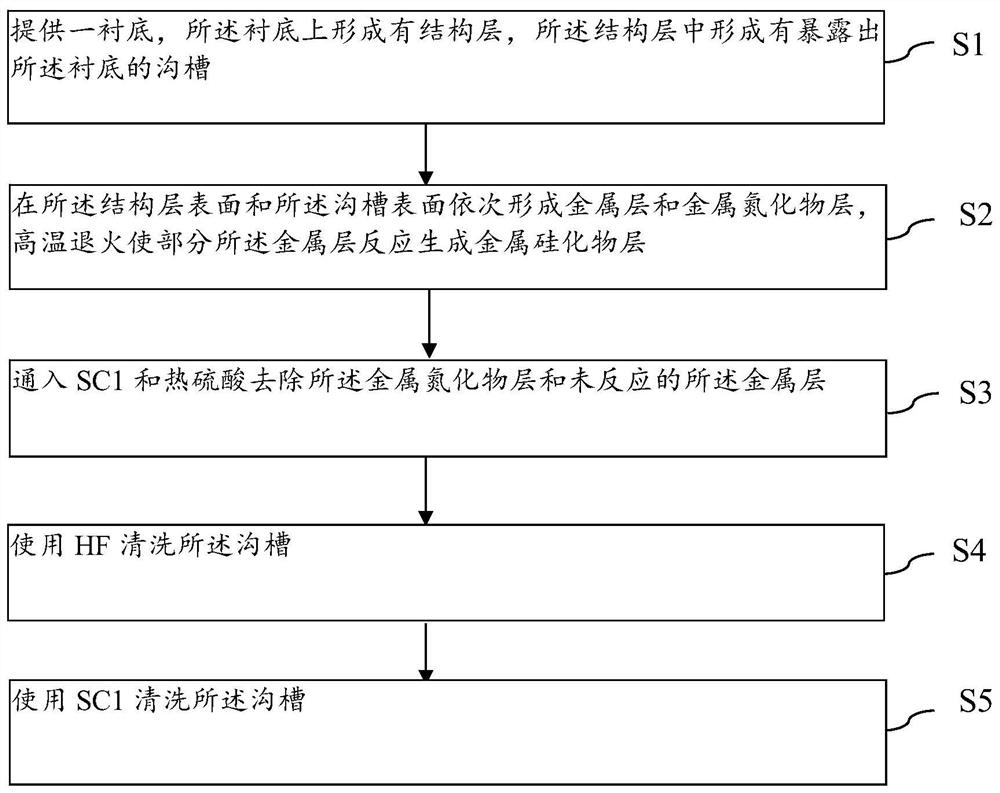

[0027] Embodiments of the present invention provide a semiconductor device and a manufacturing method thereof. Below in conjunction with the accompanying drawings and specific embodiments

[0029] providing a substrate on which a structural layer is formed, in which a structure layer exposing the substrate is formed

[0033] The trenches are cleaned using SC1.

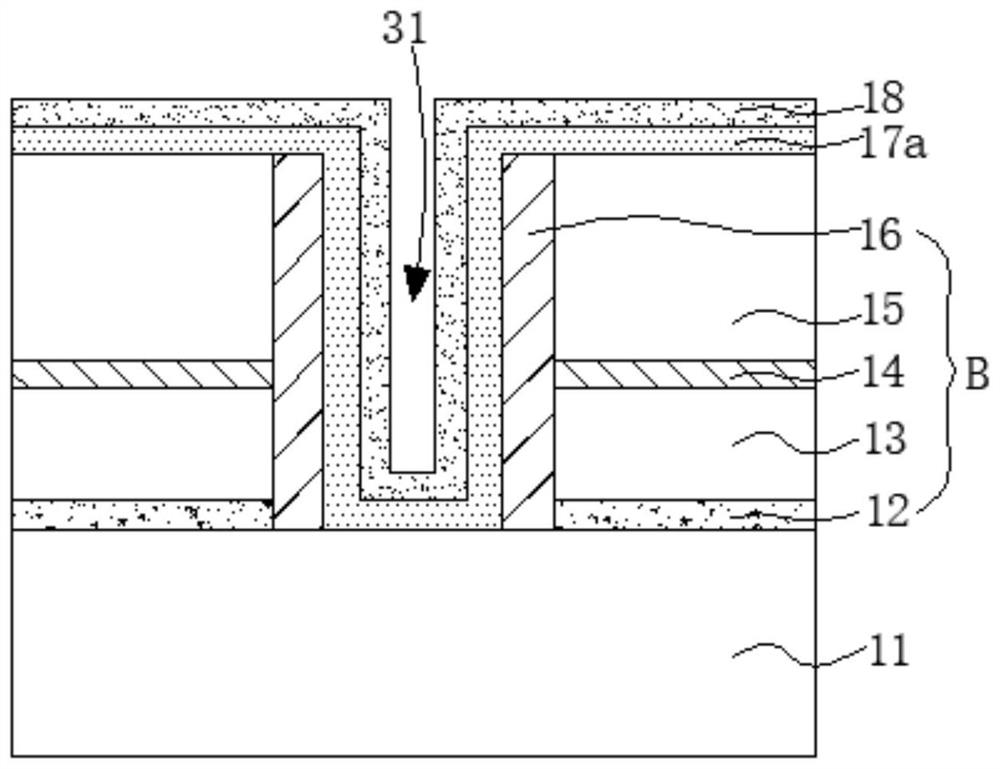

[0034] The steps of the manufacturing method of the semiconductor device of the present embodiment are described below with reference to FIGS. 3 to 7 .

[0035] As shown in FIG. 3 and FIG. 4, a substrate 11 is provided on which a structural layer B is formed, and the structural layer B is

[0037] The substrate 11 can provide an operating platform for the subsequent process, which can be any use known to those skilled in the art.

[0038] As shown in FIG. 3 to FIG. 5, the metal nitride layer 18 and the unreacted gold are removed by feeding SC1 and hot sulfuric acid.

[0039] As shown in FIG. 5 and FIG. 6, the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com