Bark-like polypropylene/polycarbonate nanofiber meltblown air filter material and preparation method thereof

A technology of polycarbonate and nanofiber, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as high cost and complicated process, and achieve the effect of improving the ability to intercept atmospheric particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

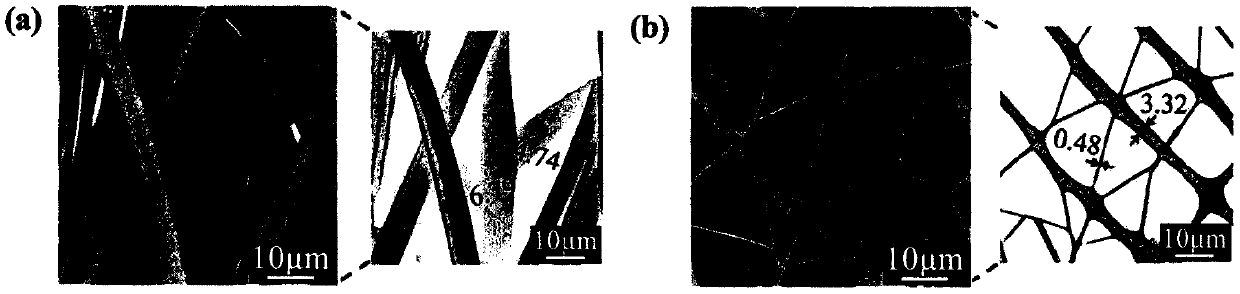

[0023] The technical problem to be solved by the present invention is to invent a method for preparing bark-like polypropylene / polycarbonate nanofiber melt blown air filter material.

[0024] Step 1. Dry the polypropylene and polycarbonate polymer with a mass ratio of 95:5 in a blast drying oven at 80°C and 120°C for 2h and 4h, respectively. The melt index and melting point of polypropylene are 35g / 10min and 169℃, the melt index and melting point of polycarbonate are 14.4g / 10min and 250℃ respectively; after drying, the polycarbonate and polypropylene are uniformly mixed and pelletized by a single screw pelletizer; pelletizing cycle 2 Two-component polypropylene / polycarbonate masterbatch was prepared after the second time; the temperature of screw 1, screw 2, screw 3, and die head of the single-screw granulator were 240, 260, 275, and 200 ℃ respectively, and single-screw granulation The screw speed and cutting speed of the machine are 21r·min respectively -1 And 32r·min -1 ;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com