Static cotton material and preparation method and application thereof

A technology of electrostatic cotton and raw materials, applied in the field of electrostatic cotton materials, can solve the problems of strong odor, obvious static attenuation, poor durability, etc., and achieve the effects of low high temperature filtration effect attenuation, strong charge retention ability, and beautiful cloth style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

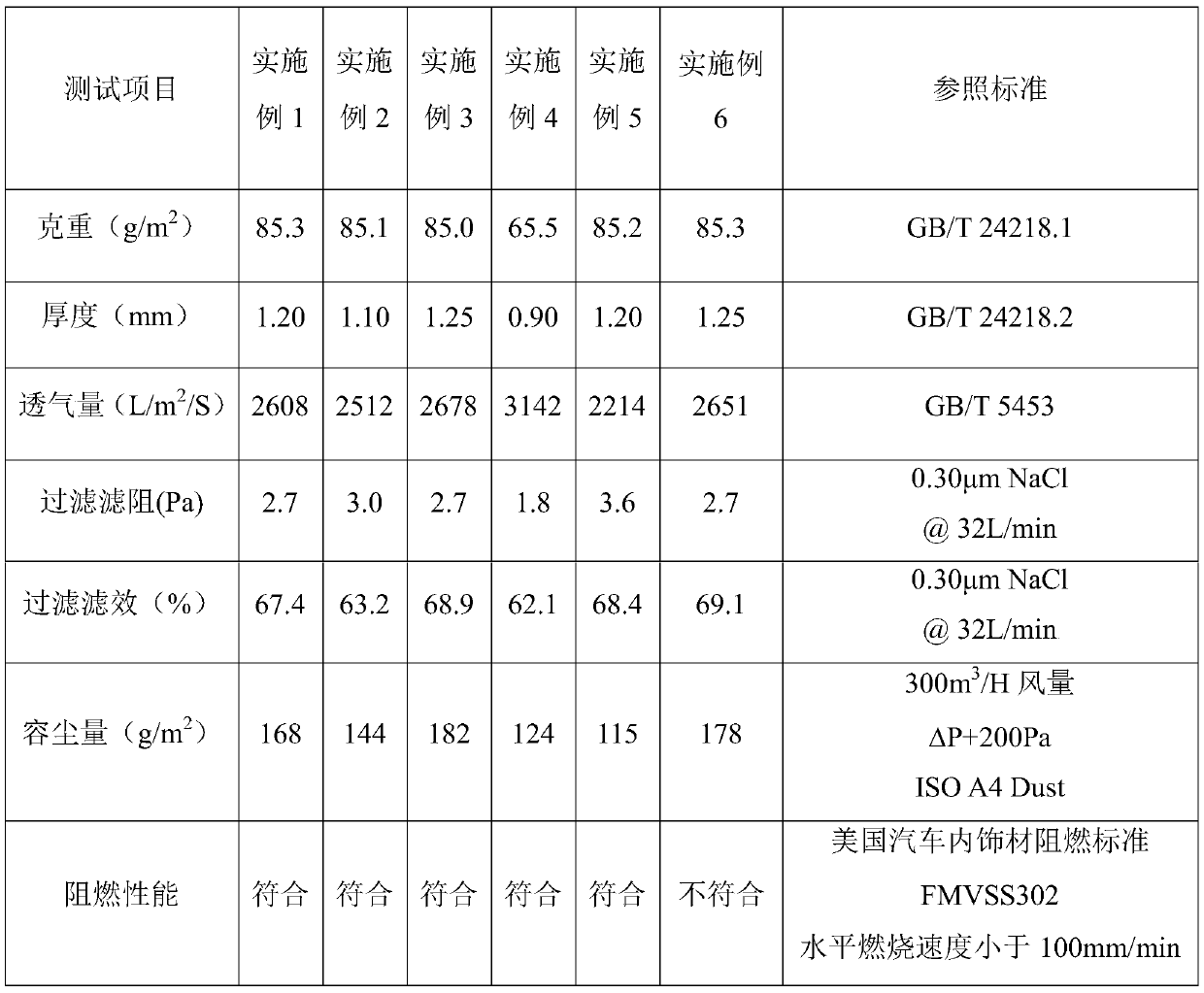

Examples

Embodiment 1

[0054] The production of the embodiment of the present invention mainly includes the following steps:

[0055] Component A polymer is homopolypropylene, melting point 158~168℃;

[0056] The B-component polymer is a polyester chip treated with phosphorus-based flame retardant modification, with a melting point of 235-255°C and an oxygen index greater than 28%.

[0057] Parallel two-component matching ratio A: B=45:55 (mass ratio)

[0058] The two polymers mentioned above are polyolefin and polyester polymers. The former does not need to be baked by a single-screw extruder for direct melting and extrusion, while the latter requires a baking treatment at 155°C for 9 hours and then a single screw. The extruder performs melt extrusion.

[0059] The raw material of component A (containing 1.5wt% electret masterbatch) is melted through a single screw extruder, and its temperature zone is set to: 195℃, 205℃, 230℃, 230℃, 230℃, 230℃, 230℃, 225℃, melt temperature 225℃, screw pipe temperature 230...

Embodiment 2

[0063] The production of the embodiment of the present invention mainly includes the following steps:

[0064] Component A polymer is homopolypropylene, melting point 158~168℃;

[0065] The B-component polymer is a polyester chip treated with phosphorus-based flame retardant modification, with a melting point of 235-255°C and an oxygen index greater than 28%.

[0066] Parallel two-component collocation ratio A: B = 41:59 (mass ratio)

[0067] The two polymers mentioned above are polyolefin and polyester polymers. The former does not need to be baked by a single-screw extruder for direct melting and extrusion, while the latter requires a baking treatment at 155°C for 9 hours and then a single screw. The extruder performs melt extrusion.

[0068] The raw material of component A (containing 1.5% electret masterbatch) is melted through a single screw extruder, and its temperature zone is set to: 195℃, 205℃, 230℃, 230℃, 230℃, 230℃, 230℃, 225 ℃, melt temperature 225℃, screw pipe temperature...

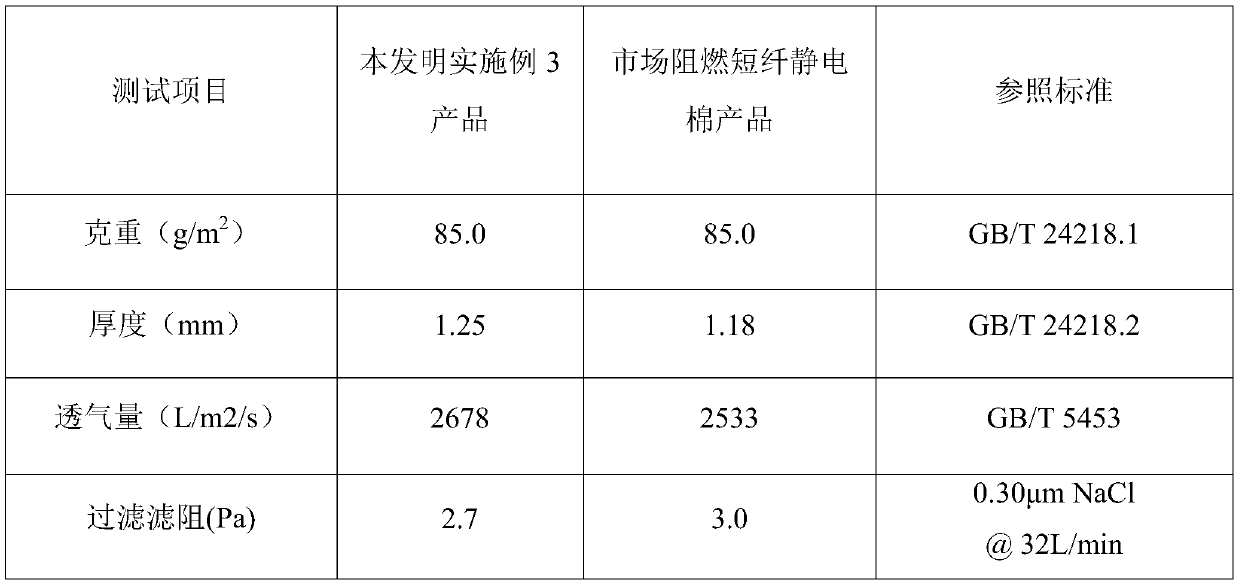

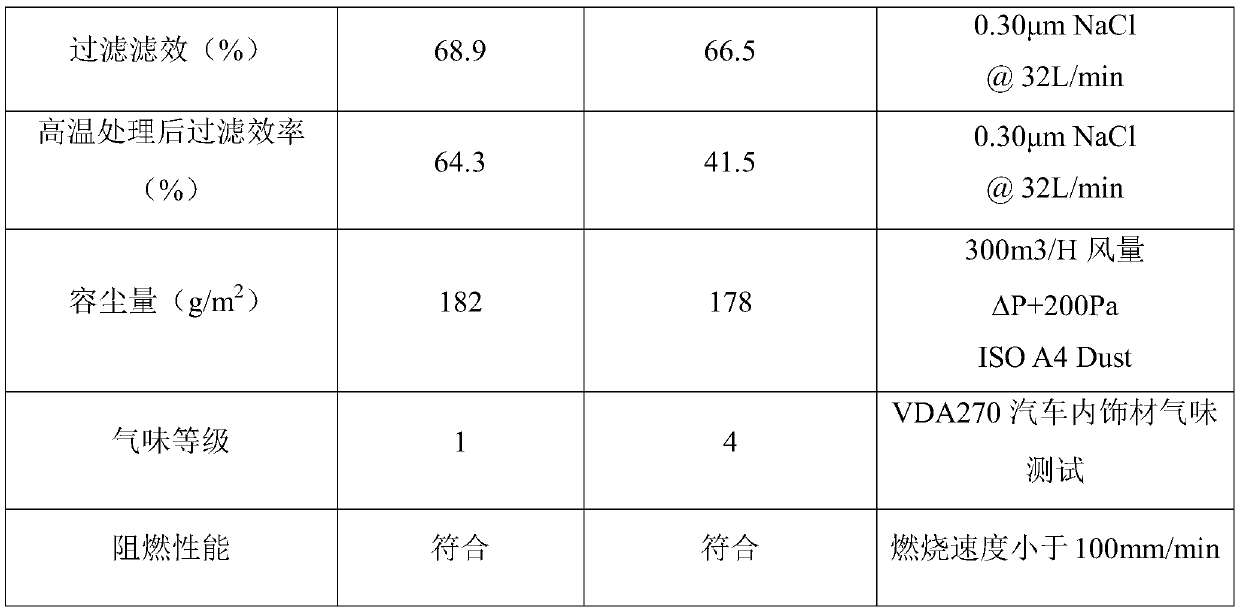

Embodiment 3

[0072] The production of the embodiment of the present invention mainly includes the following steps:

[0073] Component A polymer is homopolypropylene, melting point 158~168℃;

[0074] The B-component polymer is a polyester chip treated with phosphorus-based flame retardant modification, with a melting point of 235-255°C and an oxygen index greater than 28%.

[0075] Parallel two-component matching ratio A: B=48:52 (mass ratio)

[0076] The two polymers mentioned above are polyolefin and polyester polymers. The former does not need to be baked by a single-screw extruder for direct melting and extrusion, while the latter requires a baking treatment at 155°C for 9 hours and then a single screw. The extruder performs melt extrusion.

[0077] The raw material of component A (containing 1.5% electret masterbatch) is melted through a single screw extruder, and its temperature zone is set to: 195℃, 205℃, 230℃, 230℃, 230℃, 230℃, 230℃, 225 ℃, melt temperature 225℃, screw pipe temperature 230℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com