PCM plate for air conditioner outdoor unit and production process of PCM plate

A technology for outdoor units and substrates of air conditioners, which can be applied to coatings, special surfaces, pretreated surfaces, etc., and can solve the problems of salt spray corrosion of color-coated panels, poor tensile properties of top coats and base coats, and achieve strong resistance. Corrosion performance, good corrosion resistance effect, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

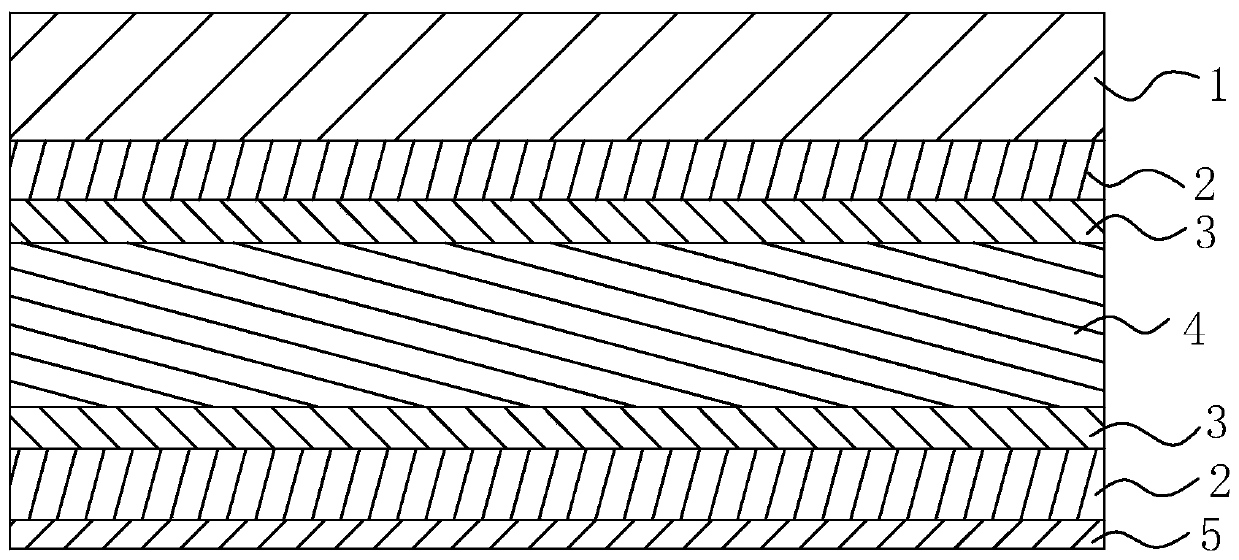

Image

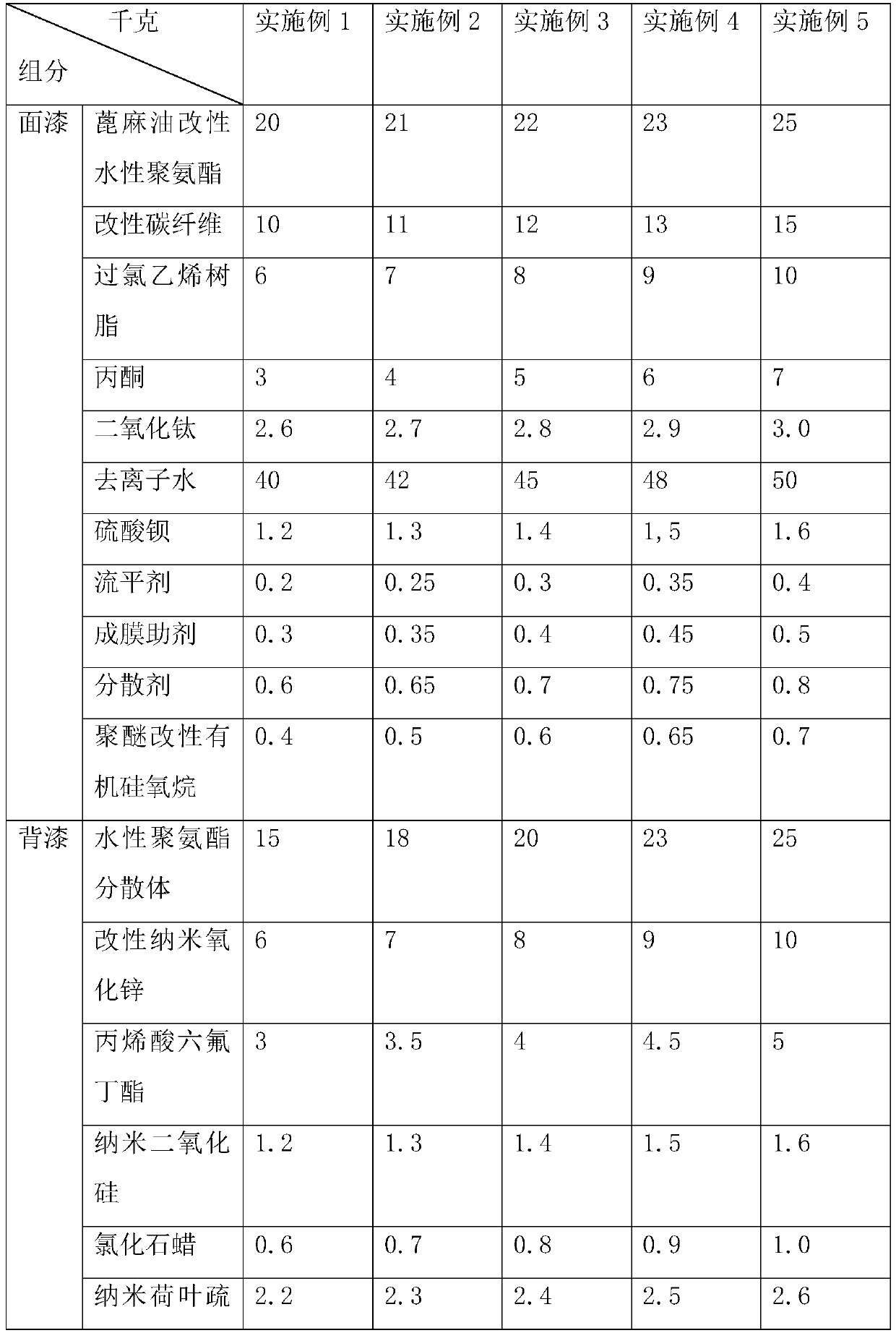

Examples

preparation example 1

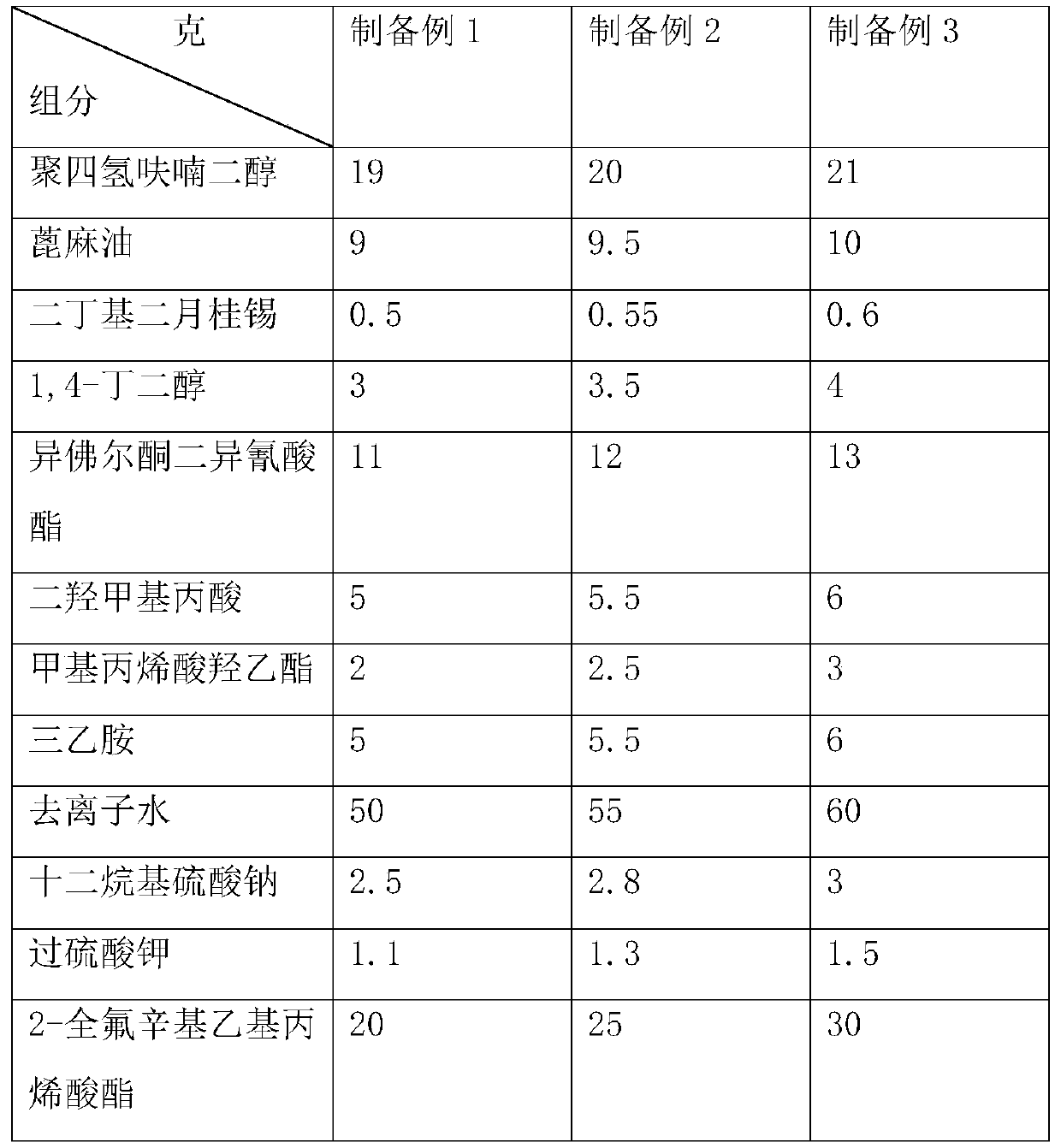

[0043] Preparation Example 1: According to the raw material ratio in Table 1, dry 19g of polytetrahydrofuran diol at 80°C for 2 hours at a constant temperature, take it out, add 9g of castor oil, 0.5g of dibutyl dilaurate, 3g of 1,4-butanediol Alcohol, 11g isophorone diisocyanate and 5g dimethylolpropionic acid, stirred for 2h, added 2g of hydroxyethyl methacrylate to continue the reaction for 0.8h, cooled to 35°C, added 5g of triethylamine for neutralization for 30min, added 50g of deionized water was stirred for 30 minutes, 2.5g of sodium lauryl sulfate, 1.1g of potassium persulfate and 20g of 2-perfluorooctyl ethyl acrylate were added, and stirred for 3 hours to obtain a modified waterborne polyurethane.

[0044] The raw material consumption of castor oil modified waterborne polyurethane in table 1 preparation example 1-3

[0045]

preparation example 2

[0046] Preparation Example 2: According to the ratio of raw materials in Table 1, 20g of polytetrahydrofuran diol was dried at a constant temperature of 85°C for 1.5h, taken out, and added with 9.5g of castor oil, 0.55g of dibutyl dilaurate, 3.5g of 1,4 -Butanediol, 12g isophorone diisocyanate and 5.5g dimethylol propionic acid, stirred for 2.5h, added 2.5g hydroxyethyl methacrylate to continue the reaction for 0.9h, cooled to 38°C, added 5.5g tris Ethylamine was neutralized for 28 minutes, 55g of deionized water was added, stirred for 28 minutes, 2.8g of sodium lauryl sulfate, 1.3g of potassium persulfate and 25g of 2-perfluorooctyl ethyl acrylate were added, and stirred for 3.5 hours to obtain the modified Waterborne polyurethane.

preparation example 3

[0047] Preparation Example 3: According to the raw material ratio in Table 1, dry 21g of polytetrahydrofuran diol at 90°C for 1 hour at a constant temperature, take it out, add 11g of castor oil, 0.6g of dibutyl dilaurate, 6g of 1,4-butanediol Alcohol, 13g isophorone diisocyanate and 6g dimethylolpropionic acid, stirred for 3h, added 3g hydroxyethyl methacrylate to continue the reaction for 1h, cooled to 40°C, added 6g triethylamine for neutralization for 25min, added 50g Deionized water, stirred for 25 minutes, added 3g of sodium lauryl sulfate, 1.5g of potassium persulfate and 30g of 2-perfluorooctyl ethyl acrylate, stirred for 4 hours to prepare a modified waterborne polyurethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com