Method for preparing high-adsorption ceramsite by using biochar

A technology of high adsorption and biochar, applied in the direction of chemical instruments and methods, applications, household appliances, etc., can solve the problem of low adsorption, achieve the effect of simple and easy preparation process, enhance adsorption, and improve ion exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

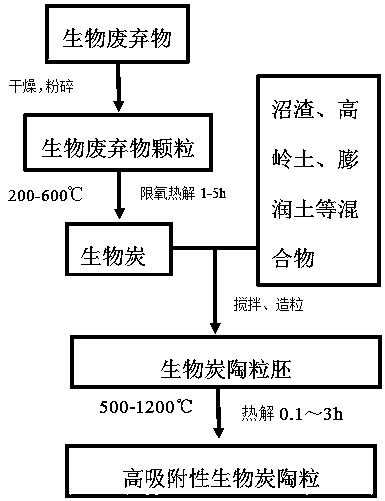

[0022] The method of a kind of highly adsorptive biochar ceramsite of the present embodiment, flow process is as follows figure 1 As shown, the specific steps are as follows:

[0023] 1. Waste treatment: Sampling biogas residue waste, drying, crushing, and passing through a 80-mesh sieve.

[0024] 2. Preparation of biochar: put the dried and pulverized biogas residue into a closed apparatus, make a homemade crucible, pyrolyze it in a muffle furnace at 450° C. for 4 hours, and cool it to room temperature to obtain biochar.

[0025] 3. Production of ceramsite embryo: choose biochar, biogas residue powder, kaolin powder, bentonite powder and dolomite powder and mix thoroughly, and the weight ratio is 3:2:3:9:3. Granulate through a disc granulator to obtain ceramsite embryos.

[0026] 4. Preparation of high-adsorption biochar ceramsite: put the ceramsite embryo into a muffle furnace, roast at 1000°C for 0.5h, cool down, and pulverize.

[0027] 5. The commercially available cera...

Embodiment 2

[0029] The method of a kind of highly adsorptive biochar ceramsite of the present embodiment, flow process is as follows figure 1 As shown, the specific steps are as follows:

[0030] 1. Waste treatment: Sampling rice husk waste, drying, crushing, and passing through 80-mesh sieve.

[0031] 2. Preparation of biochar: Put the dried and pulverized rice husk waste particles into a closed apparatus, make a crucible, and pyrolyze in a muffle furnace at 500°C for 3h, and cool to room temperature to obtain biochar.

[0032] 3. Production of ceramsite embryo: select biochar, kaolin powder, montmorillonite powder, bentonite powder, diatomite powder and dolomite powder and mix thoroughly, and the weight ratio is 2:2:8:5:1:1. Granulate through a disc granulator to obtain ceramsite embryos.

[0033] 4. Preparation of high-adsorption biochar ceramsite: put the ceramsite embryo into a muffle furnace, roast at 1100°C for 0.4h, cool down, and pulverize.

[0034] 5. Adsorb malodorous gas H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com