Cooling material with electrocaloric effect

An electric card effect and matrix technology, applied in the field of composite materials, can solve the problems of inability to industrialize, restrict the application of electric card refrigeration devices, etc., and achieve the effects of loose experimental conditions, economic cost savings, high electric card effect and electric card coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

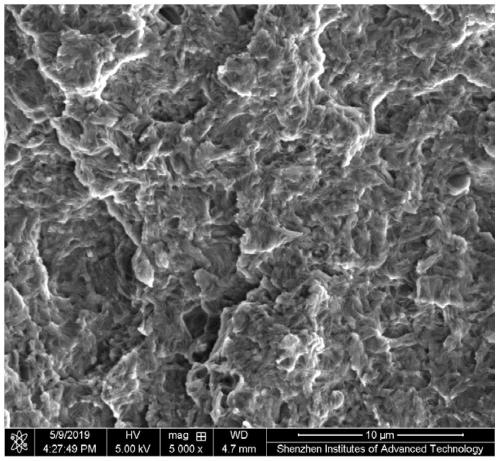

[0034] Example 1: Ba(Ti 0.96 Nb 0.04 )O 3 Preparation of / P(VDF-TrFE-CFE) composites

[0035] 1. Put 2.4g of sodium hydroxide into a beaker, add water to 60ml, then take 3.05g of barium chloride dihydrate into the aqueous solution of sodium hydroxide, stir at 80°C for 2 hours, then add 0.96g of titanium dioxide to it and 0.07 g of H 5 Nb 3 o 10 , and then fully mixed, put into a vacuum kettle, heated to 200°C, kept for 20h, collected the product, rinsed with low-concentration hydrochloric acid, water and ethanol, dried at 80°C for 12h, and the product obtained was Ba(Ti 0.96 Nb 0.04 )O 3 round particles.

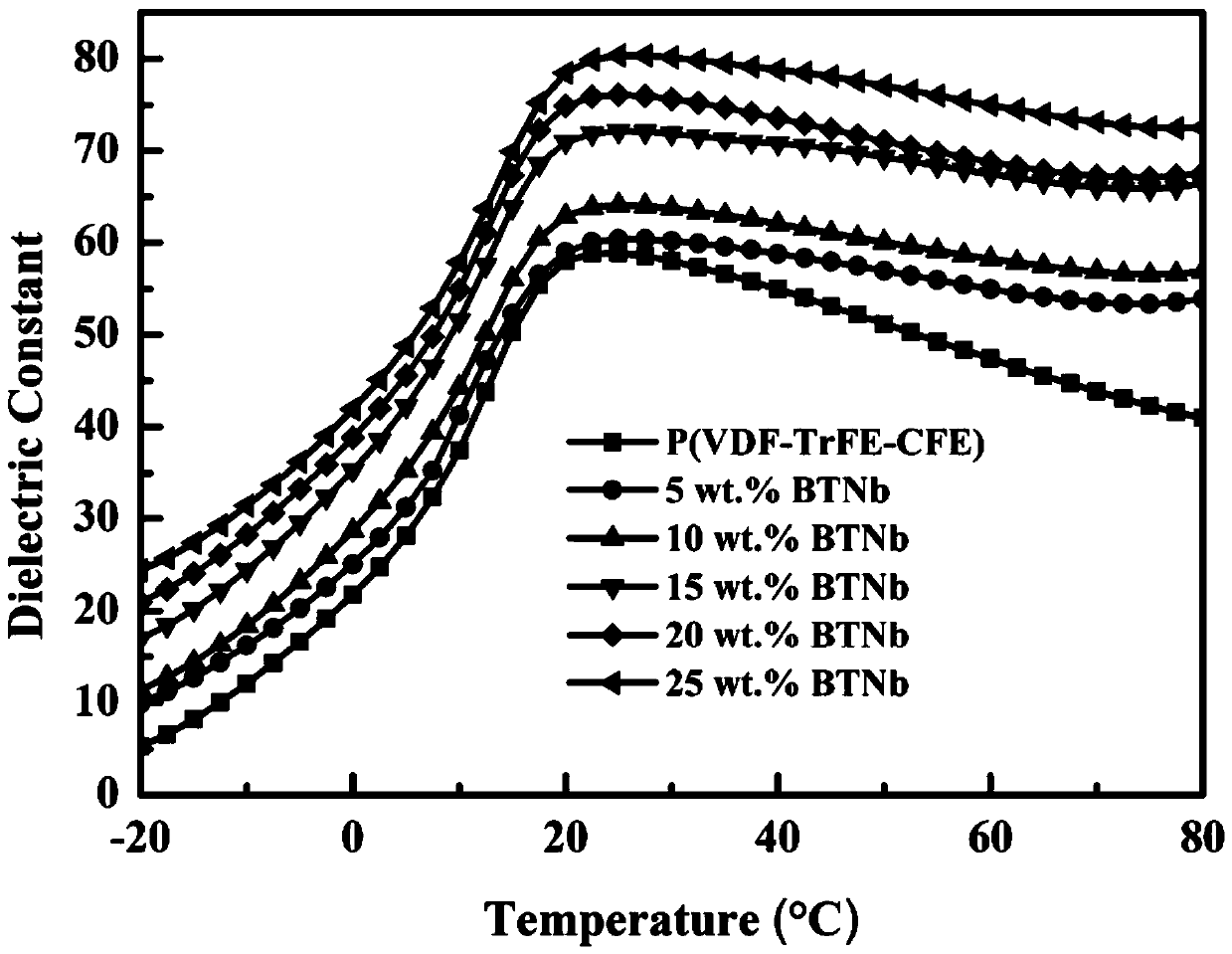

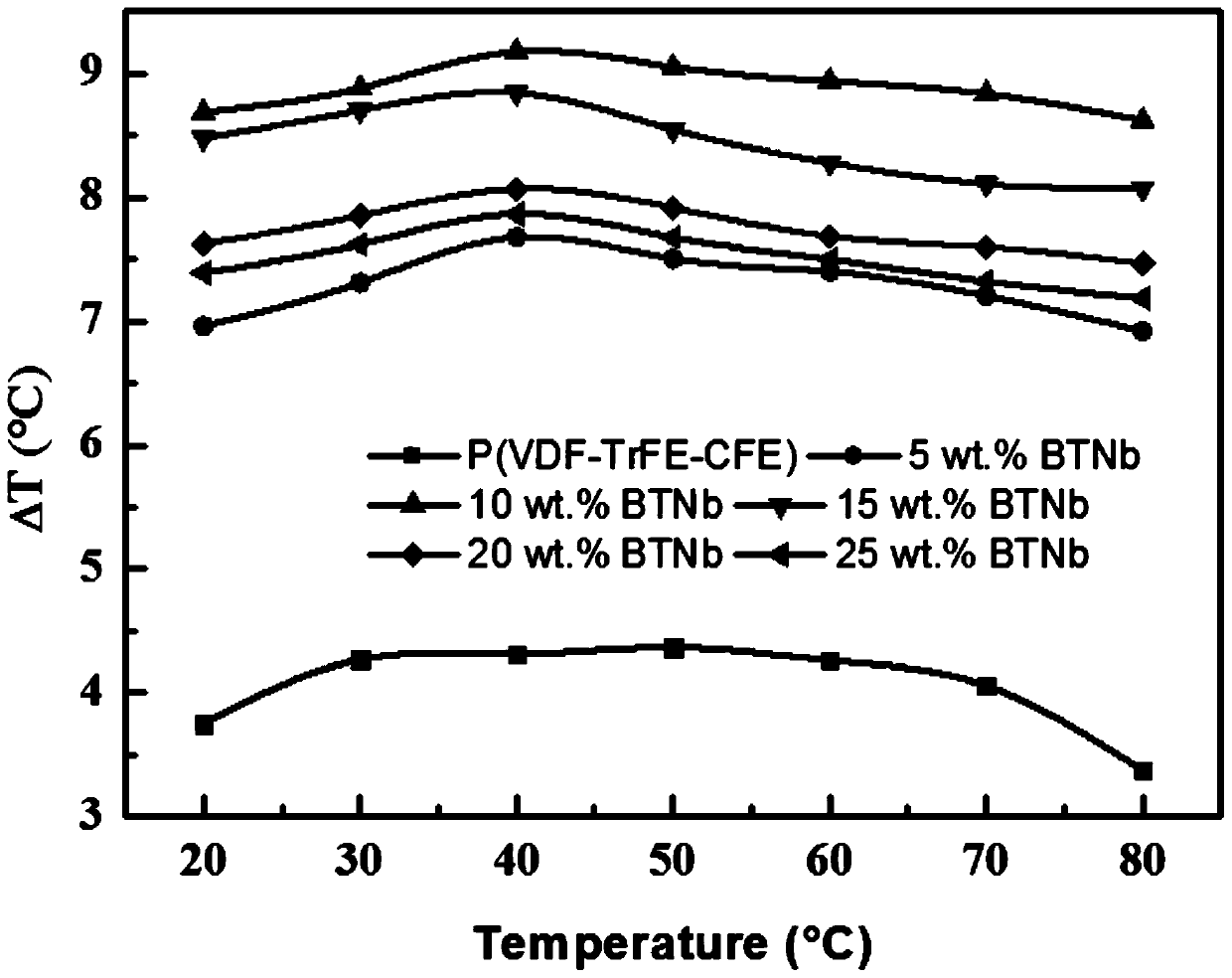

[0036] 2. Weigh 1g Ba(Ti 0.96 Nb 0.04 )O 3 and 1g of polymer P(VDF-TrFE-CFE), which were respectively added to 9g of N.N-dimethylformamide, stirred thoroughly, and dispersed to a stable suspension by ultrasonic vibration. Then take 0.11g, 0.22g, 0.35g, 0.5g, 0.67g Ba(Ti 0.96 Nb 0.04 )O 3 Put the suspension and 2g of the polymer suspension in a beaker, and stir...

Embodiment 2

[0038] Example 2: Ba(Ti 0.97 Nb 0.03 )O 3 Preparation of / P(VDF-TrFE-CFE) composites

[0039] 1. Weigh 3.63g of barium carbonate, 1.43g of titanium dioxide, 0.07g of niobium pentoxide and a certain amount of ethanol solution, pour the balls, materials, and ethanol into the ball mill jar in an appropriate proportion, and use a planetary ball mill to carry out mixed wet milling for 24 hours , then take it out and dry it, and put it in a muffle furnace at 1000°C for 5 hours. The resulting product is Ba(Ti 0.97 Nb 0.03 )O 3 round particles.

[0040] 2. Weigh 1g Ba(Ti 0.97 Nb 0.03 )O 3 and 1g of polymer P(VDF-TrFE-CFE), which were respectively added to 9g of N.N-dimethylformamide, stirred thoroughly, and dispersed to a stable suspension by ultrasonic vibration. Then take 0.11g, 0.22g, 0.35g, 0.5g, 0.67g Ba(Ti 0.97 Nb 0.03 )O 3 Put the suspension and 2g of the polymer suspension in a beaker, and stir thoroughly at a stirring speed of 1000r / min, so that the ceramic parti...

Embodiment 3

[0042] Embodiment 3: Ba(Ti 0.958 Nb 0.042 )O 3 Preparation of / P(VDF-TrFE-CFE) composites

[0043] 1. Weigh 3.26g of barium oxide, 1.63g of titanium dioxide, 0.12g of niobium pentoxide and a certain amount of ethanol solution, pour the balls, materials, and ethanol into the ball mill jar in an appropriate proportion, and use a planetary ball mill for mixed wet milling for 24 hours , then take it out and dry it, and put it in a muffle furnace at 1000°C for 5 hours. The resulting product is Ba(Ti 0.958 Nb 0.042 )O 3 round particles.

[0044] 2. Weigh 1g Ba(Ti 0.958 Nb 0.042 )O 3 and 1g of polymer P(VDF-TrFE-CFE), which were respectively added to 9g of N.N-dimethylformamide, stirred thoroughly, and dispersed to a stable suspension by ultrasonic vibration. Then take 0.22g, 0.27g, 0.33g, 0.38g Ba(Ti 0.958 Nb 0.042 )O 3 Put the suspension and 2g of the polymer suspension in a beaker, and stir thoroughly at a stirring speed of 1000r / min, so that the ceramic particles are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com