Magnetic surface molecularly imprinted polymer and preparation method and application thereof

A surface molecular imprinting and polymer technology, applied in the direction of electrochemical variables of materials, can solve the problems of poor selectivity and low sensitivity, and achieve the effect of high accuracy, high sensitivity and improving the degree of polymerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

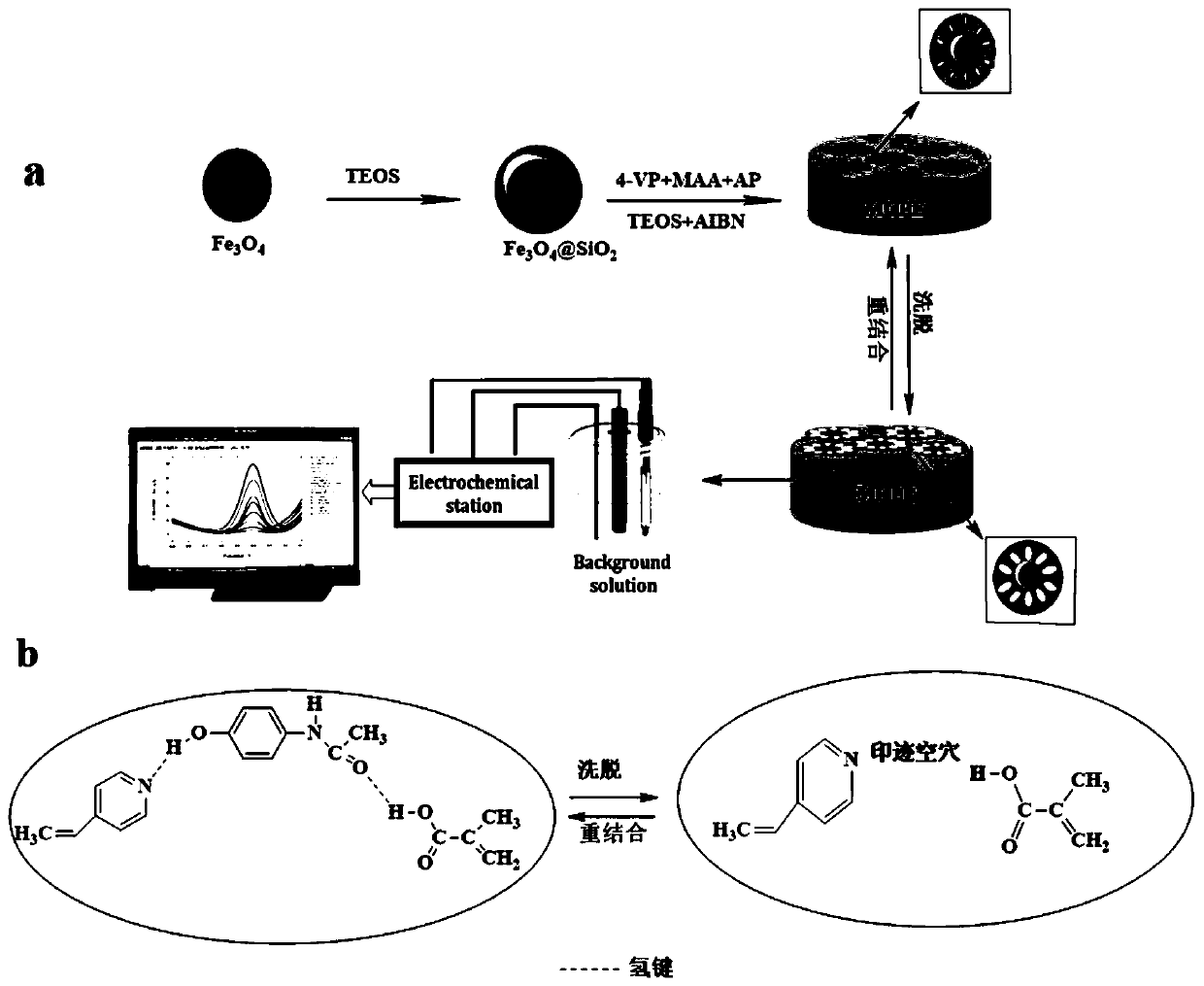

[0043] This example provides a method for preparing a molecularly imprinted polymer on a magnetic surface, such as figure 1 a. figure 1 b, including:

[0044] Add 2.5mmol AP (template molecule), 3mmol methacrylic acid MAA (functional monomer) and 30ml tetrahydrofuran into a beaker, stir for 30min, then add 2mmol 4-VP (functional monomer), stir for 10min, then add 0.05gFe 3 o 4 @SiO 2 , 4mmol ethyl tetrasilicate TEOS (crosslinking agent), and 20mg azobisisobutyronitrile AIBN (initiator), ultrasonic 60min, deoxygenation, sealed at 35 ℃ for 6h;

[0045] The obtained molecularly imprinted polymer was eluted in an eluent of acetic acid:methanol with a volume ratio of 2:8 for 35 minutes, and the final product was separated by a magnet, washed several times with distilled water, dried in vacuum at 60°C for 8 hours, and set aside.

Embodiment 2

[0047] This embodiment provides a method for preparing an electrochemical sensor, comprising: weighing 4g of graphite powder and 1ml of paraffin oil in a beaker, mixing and stirring until a paste is formed, and then taking an appropriate amount of the paste and pressing it into a mixture with a length of about 8 cm and an inner diameter of about 8 cm. In a 4mm polypropylene plastic tube, a pencil lead with a length of about 5cm is inserted at the end of the tube as a circuit connection point, and a round NdFeB magnet (diameter 4mm, thickness 2mm) is embedded in the other end about 1.5mm, and then filled with the above prepared Coated with graphite powder 2mm, and finally polished into a smooth mirror surface on paper, the magnetic carbon paste electrode (MCPE) was obtained.

[0048] Then ultrasonically disperse 1.0 mg of the magnetic polymer (MMIP) prepared in Example 1 in 1 ml of tetrahydrofuran, get 25 μL of the suspension and evenly drop it on the surface of MCPE to obtain t...

Embodiment 3

[0050] This embodiment provides an AP detection method, including:

[0051] The CHI660C electrochemical workstation (Shanghai Chenhua Co., Ltd.) was used as the detection platform, MCPE was used as the working electrode, the calomel electrode was used as the reference electrode, and the platinum electrode was used as the counter electrode.

[0052] Perform electrochemical experiments according to the optimized conditions. Before each experiment, immerse the working electrode in 5.0mL paracetamol standard solution for recombination for 25min, then wash the surface impurities with distilled water, and immerse the above electrode in 5.0ml of 0.2mmol / L PBS buffer (pH 5.0) for detection.

[0053] DPV experiments were performed over a potential range of 0.8 V to 0 V, with a pulse width of 170 ms, a potential increment of 20 mV, a pulse amplitude of 50 mV, and a scan rate of 25 mV s -1 .

[0054] The test results are as follows:

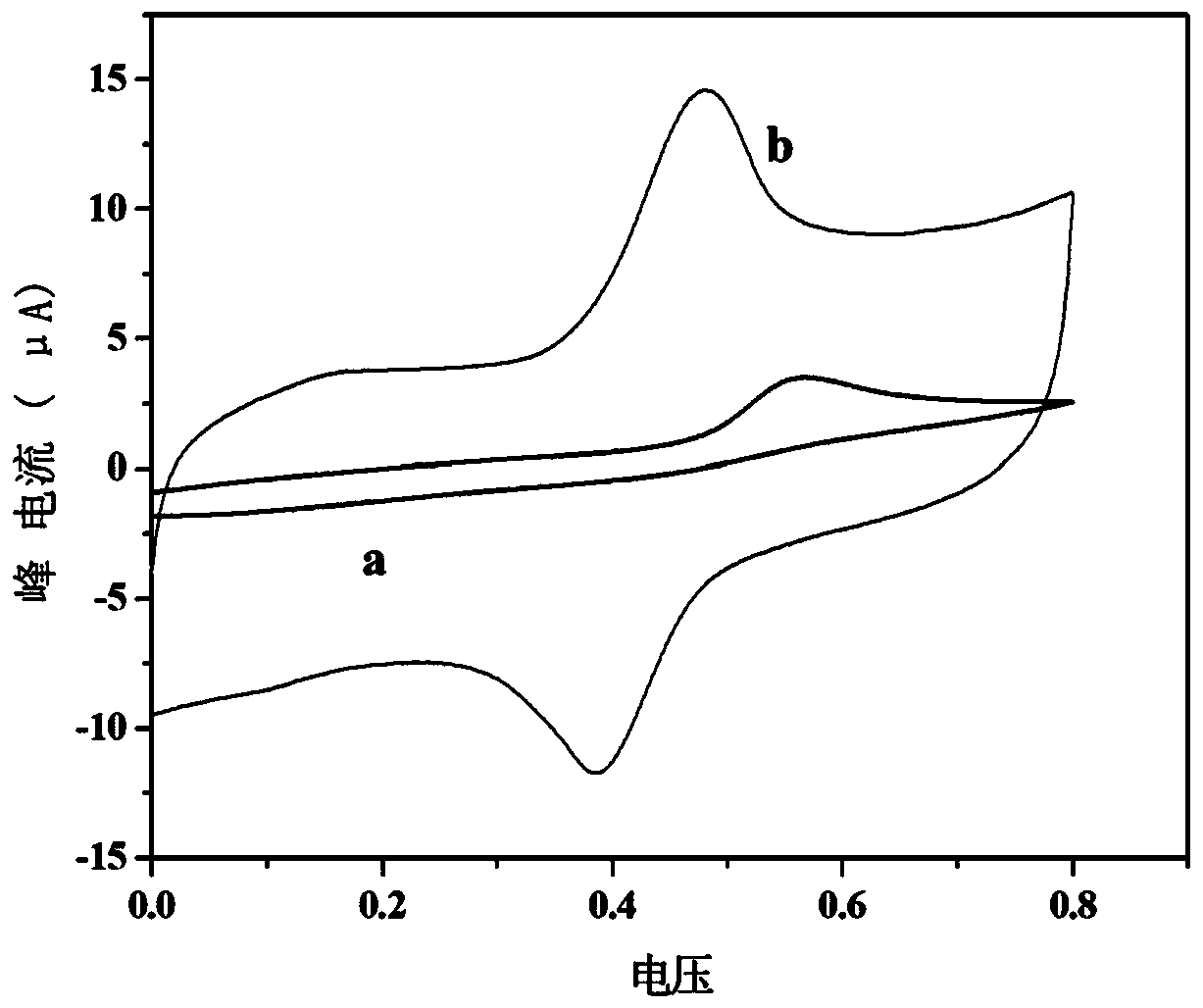

[0055] 1. Cyclic voltammetry characterization

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com