Ferrite substrate polishing method adopting acidic polishing solution and metal-based polishing disk

A polishing liquid and ferrite technology, which is used in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, low product accuracy, affecting the dielectric constant of the workpiece, and decreasing inductance L value, etc. The effect of strong chemical bonding of materials, improving processing efficiency and processing uniformity, and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

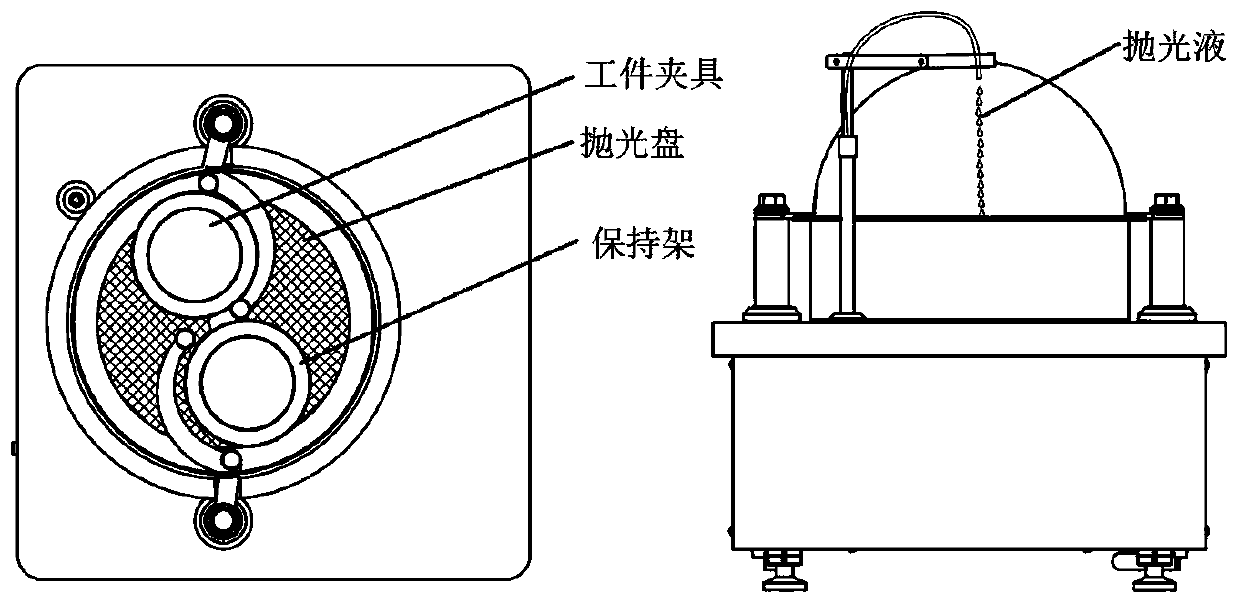

[0038] (1) Preparation of amorphous metal-based polishing disc

[0039] Step 1: Prepare mixed slurry. First put the mixed powder of abrasive, filler and amorphous alloy powder into a V-type barrel mixer and mix for 6 hours, mix evenly, pass through a 200-mesh sieve, put it into a ball mill, add water and additives and mix for 15 to 36 hours. Hour, obtain mixed slurry, concrete composition and quality are as shown in the table below:

[0040]

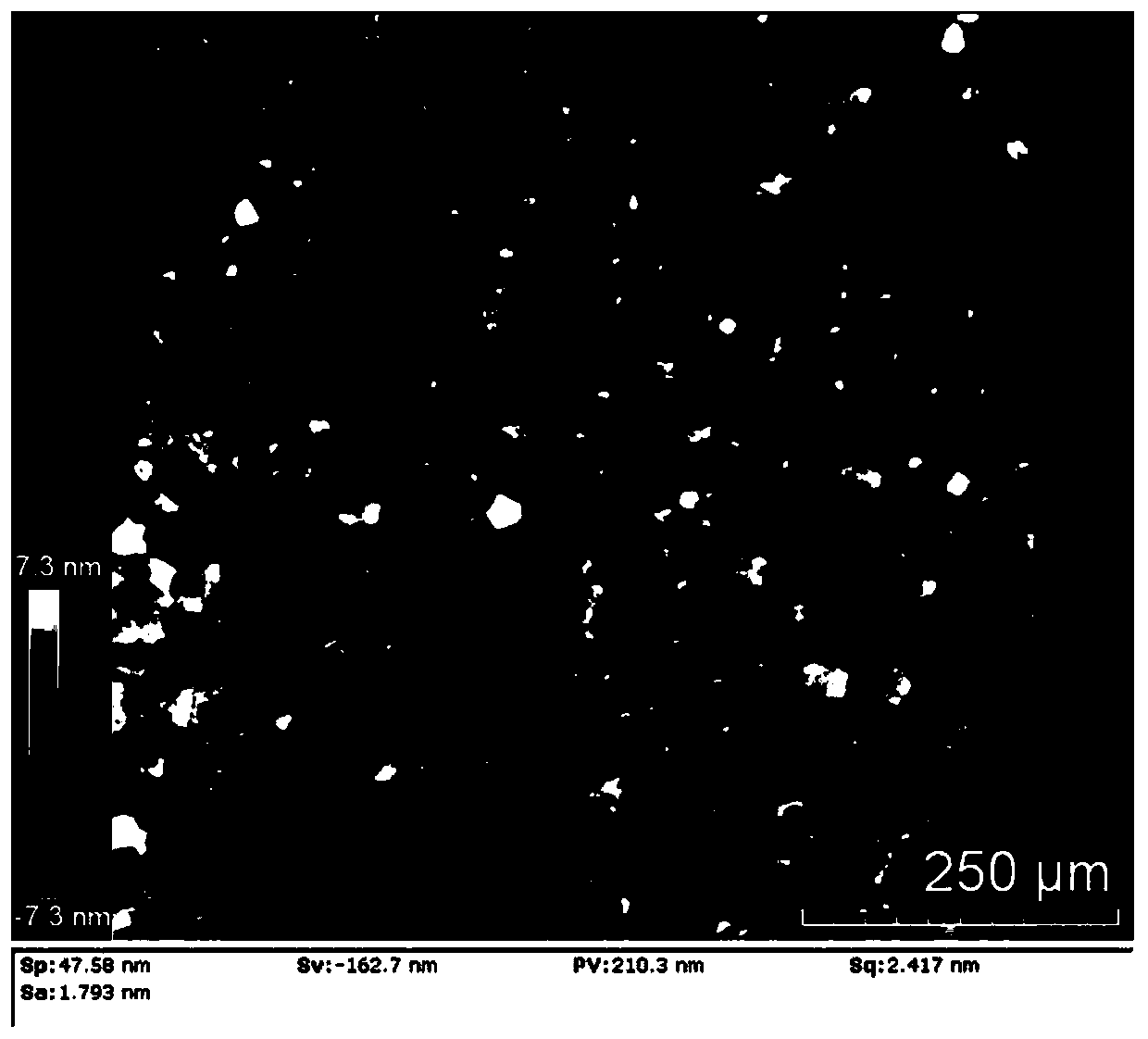

[0041] Among them, the crystal grains of alumina and zirconia are both 1 μm. If the grains are too small, the abrasive grain size will decrease, and the polishing efficiency will decrease. There will be scratches left by the previous grinding process on the surface of the ferrite substrate, resulting in The roughness of the ferrite surface is relatively large; if the crystal grains are too large, the abrasive grain size increases, and the mechanical effect of the abrasive grains on the surface of the ferrite substrate is enhanced. Ex...

Embodiment 2

[0054] The operation is basically the same as in Example 1, the difference is that in step 1, 20% iron-based nano-amorphous alloy powder is added to the iron-nickel-based amorphous alloy powder, and the particles of the amorphous nano-alloy powder are spherical and agglomerated. The diameter is 20-50nm, and the nano-scale powder improves the performance of the sintered body, improves the strength, toughness and wear resistance, and the pores are controllable. Compared with Example 1, the flexural strength of the amorphous metal-based polishing disc has reached 200kg / cm 2 , the tensile strength reached 150kg / cm 2 , the flexural strength and tensile strength are greatly improved, because when there are nanocrystals uniformly distributed on the amorphous alloy matrix, the performance of the amorphous alloy can be further optimized, and the low plasticity of the amorphous alloy can be improved while maintaining high strength. Problems, ease the stress concentration, delay the ex...

Embodiment 3

[0056] The operation is basically the same as in Example 1, the difference is that in step 1, the grains of alumina and zirconia abrasives are changed to 0.5 μm, polished for 20 minutes, and there are scratches left by the previous grinding process on the ferrite surface, rough The degree is worse than that of Example 1, and this is because the abrasive particle size decreases and the polishing efficiency decreases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com