High-temperature carburizing steel, high-temperature carburizing steel component and preparation method thereof

A high-temperature carburizing and component technology, applied in the field of steel alloys, can solve the problems of continuous casting tundish nozzle blockage and inability to mass production, and achieve the effects of inhibiting grain growth, reducing oxidation in grain boundaries, and ensuring fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of high temperature carburizing steel of the present invention

[0066] A preparation method of high-temperature carburized gear steel, and a manufacturing method for ensuring less Al-containing brittle B-type inclusions and improving the fatigue life of gears:

[0067] The first step: Converter smelting, the control target of tapping at the end point: C≥0.10%, P≤0.015%, alloying starts about 90 seconds after tapping starts, and the amount of aluminum-iron alloy added is controlled at 100±10kg; to ensure the tapping temperature ≥1610℃;

[0068] Step 2: Refining in LF ladle furnace, control the basicity of slag to 2.0-3.0, and control the flow of Ar gas at the same time to prevent the molten steel from tumbling and slag curling. Aluminum particles are used as deoxidizer and silicon carbide diffusion deoxidation for comprehensive deoxidation. The amount of aluminum particles added is 80kg±20kg. A sufficient amount of aluminum wire is fed within 10 ...

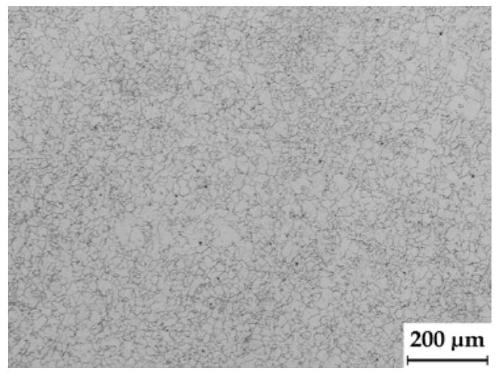

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com