Heat treatment technology for preparing high-performance low-residual stress aluminum alloy

A residual stress and aluminum alloy technology is applied in the field of heat treatment for preparing high-performance low residual stress aluminum alloys. It can solve the problems of consuming material plastic reserve, increasing plastic deformation, and demanding material shape and size, and achieves fast heating speed and reduced heat loss. The effect of small lattice distortion and good high temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

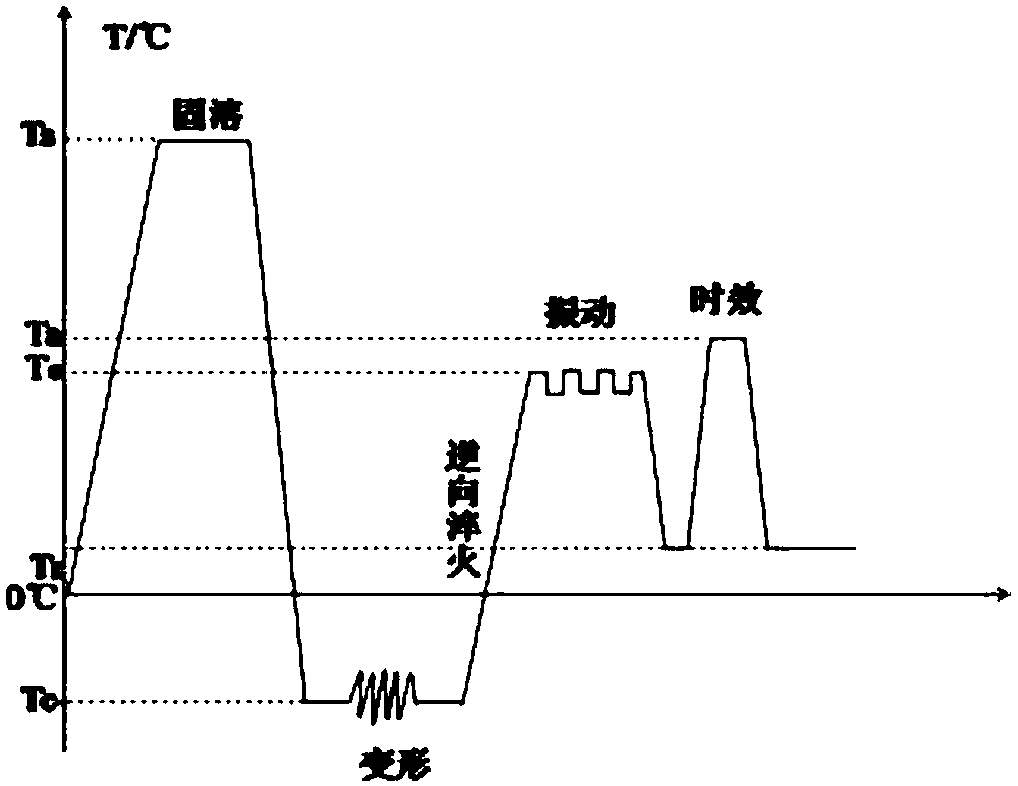

Method used

Image

Examples

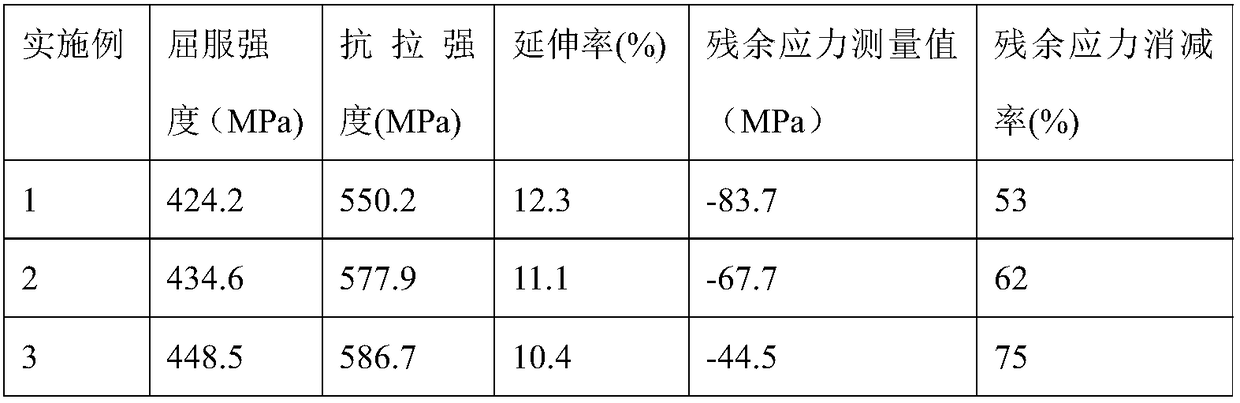

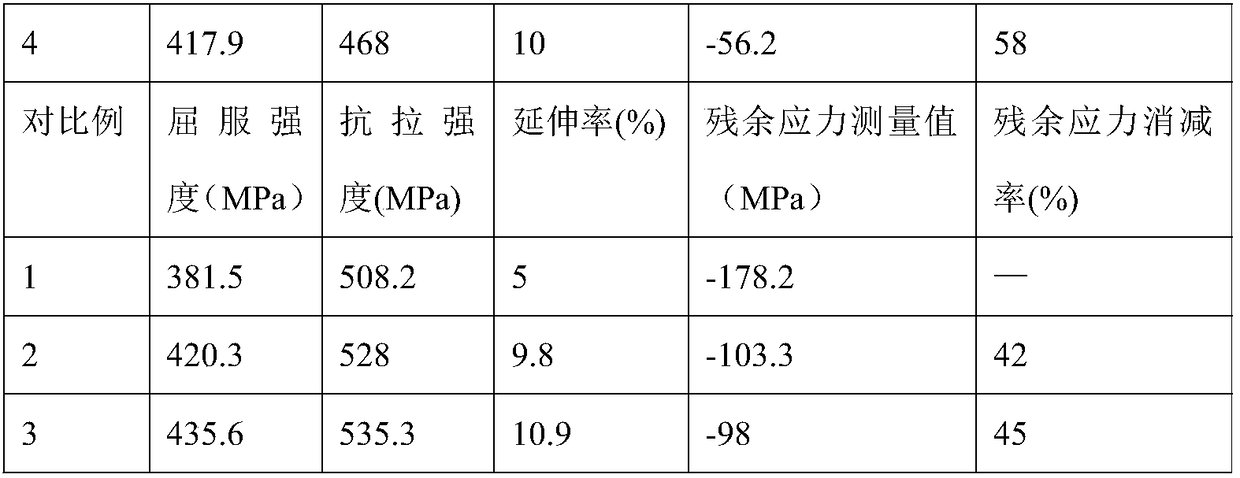

Embodiment 1

[0047] A 2xxx series alloy cold-rolled plate with a sample thickness of 6 mm was used, and its alloy composition was Al-4.45Cu-1.5Mg-0.54Mn (mass fraction %). Firstly, put the sample into an air furnace with a temperature of 495°C for 1 hour; then quench the sample at a low temperature, and then perform cryogenic deformation treatment on the quenched sample, and the deformation amount is 10%; after the cryogenic deformation treatment Immediately put it in a heat medium at 150°C for 12 minutes, and at the same time use a vibrator to vibrate it. The dynamic stress provided by the vibrator is 55MPa; finally, perform aging treatment with an aging temperature of 120°C and a time of 45h. The yield strength, tensile strength, elongation, residual stress measurement value and residual stress reduction rate of the 2xxx alloy treated in this embodiment are shown in Table 1.

Embodiment 2

[0049] A 2xxx series alloy cold-rolled plate with a sample thickness of 6 mm was used, and its alloy composition was Al-4.45Cu-1.5Mg-0.54Mn (mass fraction %). Firstly, put the sample in an air furnace with a temperature of 485°C and keep it warm for 1 hour; then the sample is subjected to low-temperature quenching, and the quenched sample is subjected to cryogenic deformation treatment, and the deformation amount is 25%; after cryogenic deformation treatment Immediately put it in a heat medium at 180°C for 10 minutes, and at the same time use a vibrator to vibrate it. The dynamic stress provided by the vibrator is 75MPa; finally, perform aging treatment with an aging temperature of 170°C and a time of 16h. The yield strength, tensile strength, elongation, residual stress measurement value and residual stress reduction rate of the 2xxx alloy treated in this embodiment are shown in Table 1.

Embodiment 3

[0051] A 2xxx series alloy cold-rolled plate with a sample thickness of 6 mm was used, and its alloy composition was Al-4.45Cu-1.5Mg-0.54Mn (mass fraction %). First, put the sample in an air furnace at 500°C for 1 hour; then quench the sample at low temperature, and then perform cryogenic deformation treatment on the quenched sample, and the deformation amount is 40%; after cryogenic deformation treatment Immediately put it in a heat medium at 200°C for 8 minutes, and at the same time, use a vibrator to vibrate it. The dynamic stress provided by the vibrator is 84MPa; finally, perform aging treatment with an aging temperature of 200°C and a time of 1.5h. The yield strength, tensile strength, elongation, residual stress measurement value and residual stress reduction rate of the 2xxx alloy treated in this embodiment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com