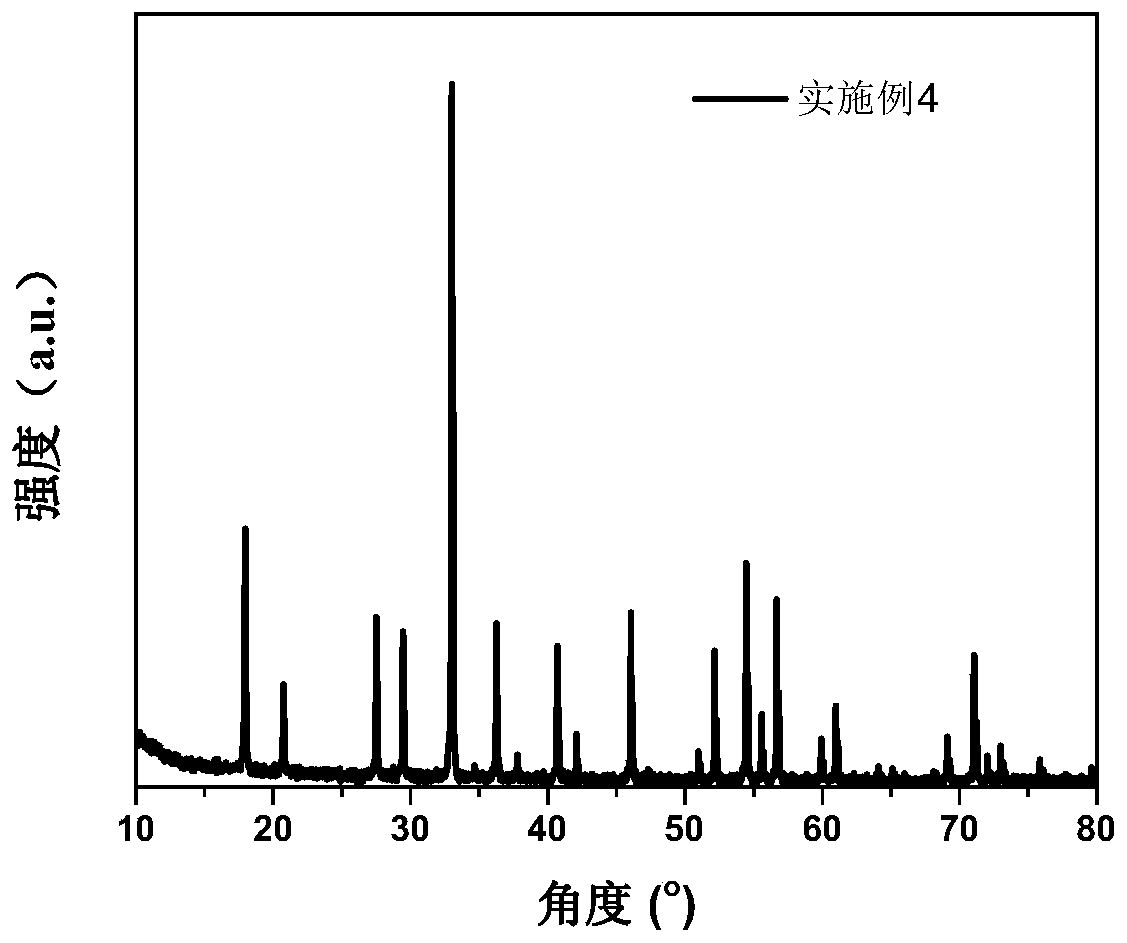

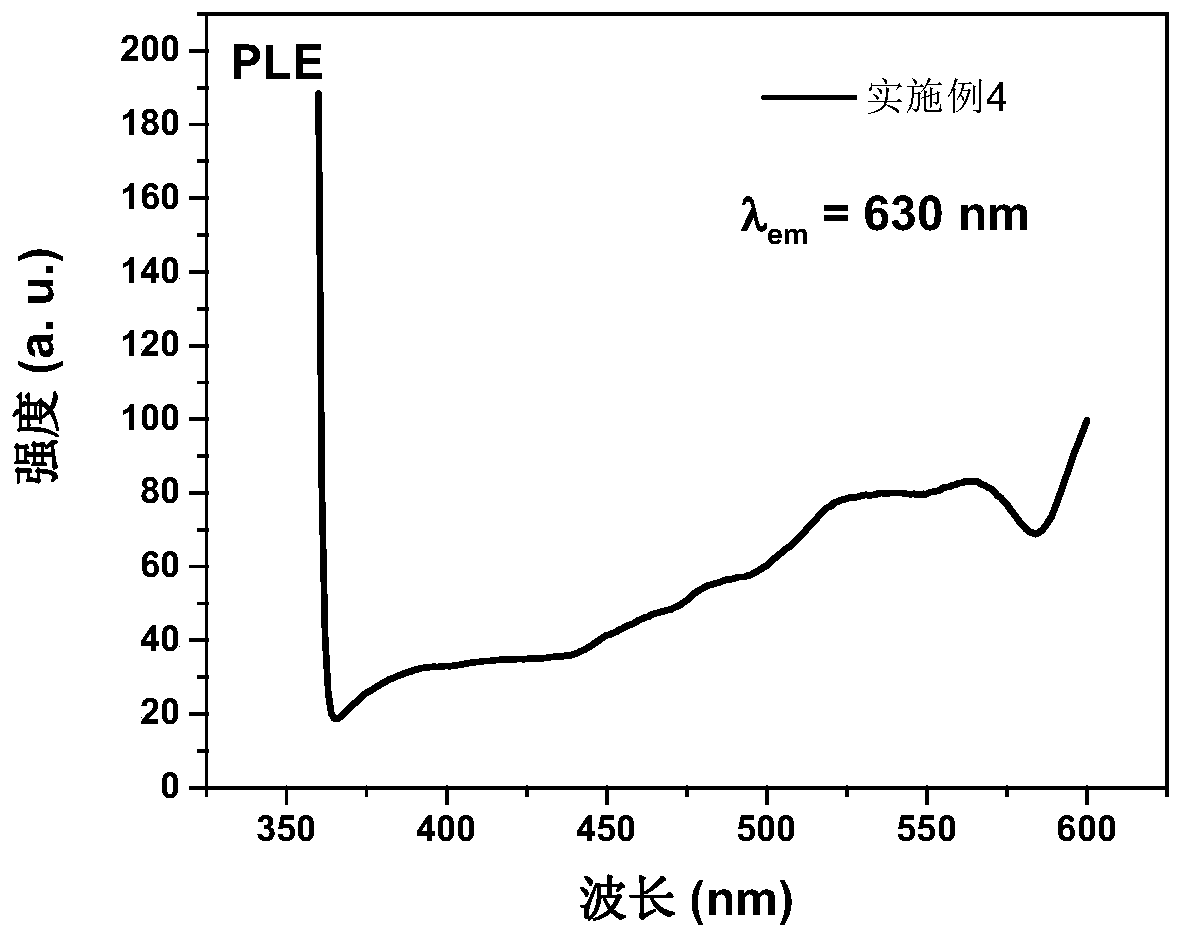

Red luminescent material and preparation method and application thereof

A technology of red light emission and emission wavelength, which is applied in the field of red light-emitting materials and its preparation, can solve the problems of low efficiency in the red light band and limit the application of red light, and achieve excellent light-emitting performance, low cost, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing the above-mentioned red luminescent material, the method comprising the following steps:

[0056] S100: According to Gd 3-x mn x al 4 GaO 12 (wherein, 0.001≤x≤0.5, x is the mole fraction) stoichiometric ratio weighs the reaction raw materials.

[0057] Preferably, the reaction raw materials are oxides, fluorides, chlorides, carbonates, borates, oxalates or acetates containing elements in the above red luminescent materials.

[0058] S200: Grinding and mixing the weighed reaction raw materials.

[0059] Generally, the grinding of the reaction raw materials is carried out in an agate mortar, and alcohol or acetone is usually added to the reaction raw materials to speed up the grinding process.

[0060] Preferably, in order to allow the reaction raw materials to fully react in the subsequent process, in step S200, the average particle size of the reaction raw materials after grinding is 300-600 mesh.

[0061] S...

Embodiment 1

[0070] Weigh 1.4995molGd 2 o 3 , 0.001molMnO 2 , 2molAl 2 o 3 , 0.5molGa 2 o 3 The reaction raw materials; mix and grind the weighed reaction raw materials evenly and put them into a high-purity corundum crucible; under the air atmosphere, sinter in a tube furnace at 1500°C for 2 hours, and then grind after cooling to room temperature with the furnace. get Gd 2.999 mn 0.001 al 4 GaO 12 Fluorescent powder, recorded as sample 1#.

Embodiment 2

[0072] Weigh 1.495molGd 2 o 3 , 0.01molMnO 2 , 2molAl 2 o 3 , 0.5molGa 2 o 3 The reaction raw materials; mix and grind the weighed reaction raw materials evenly and put them into a high-purity corundum crucible; sinter in a tube furnace at 1700°C for 5 hours in an air atmosphere, and then grind after cooling to room temperature with the furnace. get Gd 2.99 mn 0.01 al 4 GaO 12 Phosphor powder, recorded as sample 2#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com